Sep . 06, 2024 19:33 Back to list

China HDPE Pipe Sizes and Prices - Comprehensive Guide

Understanding HDPE Pipe Sizes and Prices in China

High-Density Polyethylene (HDPE) pipes have gained substantial popularity in various industries due to their robustness, flexibility, and resistance to corrosion. One of the leading producers of HDPE pipes is China, which offers a wide range of sizes and competitive pricing. This article delves into the different sizes of HDPE pipes available in China and factors influencing their prices.

HDPE Pipe Sizes

HDPE pipes are manufactured in various diameters to cater to different applications, including water supply, irrigation, drainage, and industrial uses. The most common sizes range from 20 mm to 1600 mm in diameter.

1. Small Diameter Pipes (20 mm - 63 mm) These sizes are typically used for residential applications and small-scale irrigation systems. They are lightweight and easy to handle, making them ideal for projects that require mobility and flexibility.

2. Medium Diameter Pipes (75 mm - 250 mm) These pipes are commonly used in municipal water supply systems and larger irrigation systems. They balance flexibility and strength, providing a reliable solution for transporting water over moderate distances.

3. Large Diameter Pipes (300 mm and above) These sizes are essential for industrial applications, including wastewater management, large-scale irrigation, and infrastructure projects. They support high-volume water transportation and are designed to handle significant pressure and stress.

Pricing Factors

The prices of HDPE pipes can vary significantly based on several factors

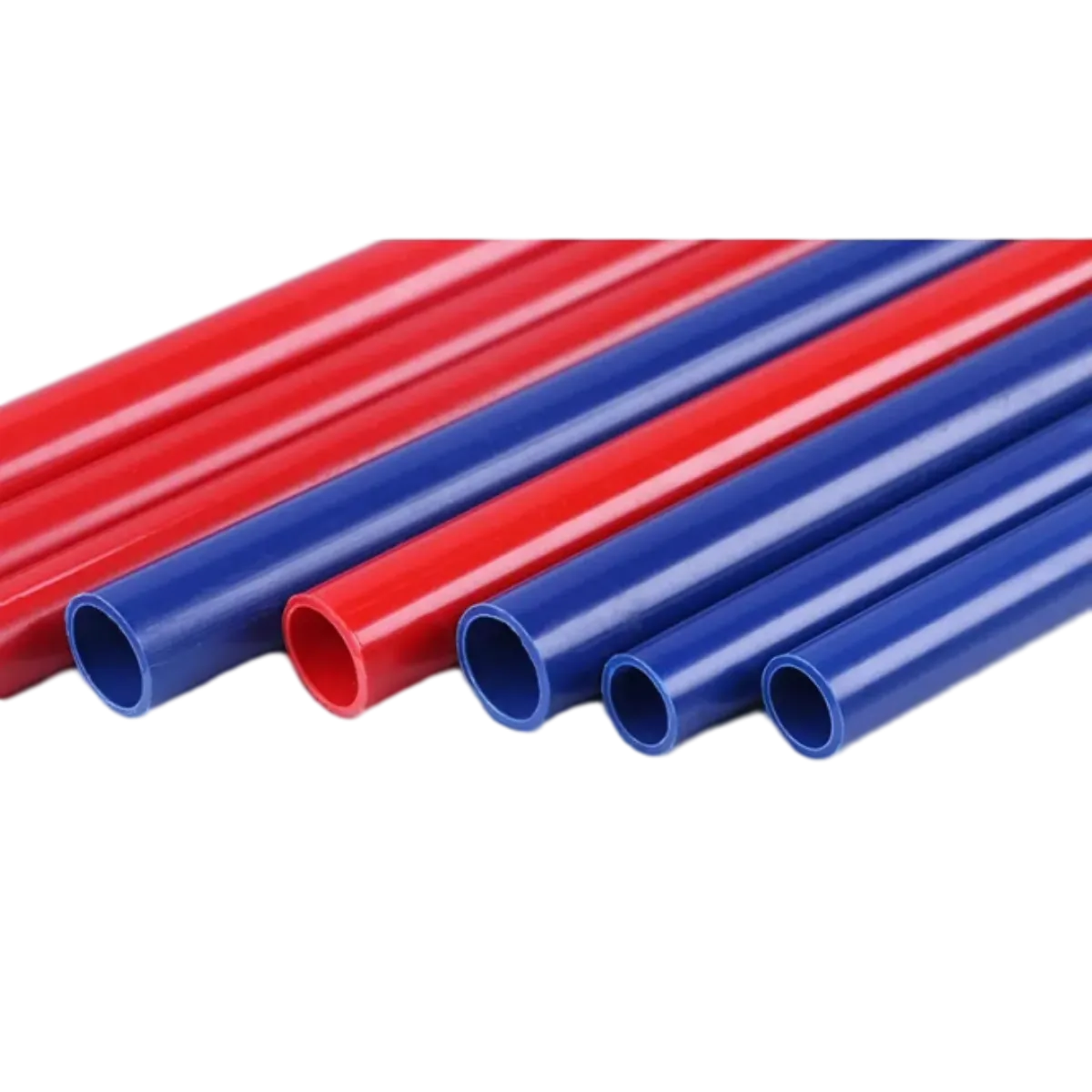

china hdpe pipe sizes and prices

1. Material Quality The quality of the polyethylene resin used in the manufacturing process plays a crucial role in pricing. Higher-quality materials generally lead to improved durability and longer service life, which may justify a higher price tag.

2. Pipe Size Larger pipes typically cost more due to the increased material requirements and the complexities involved in their production.

3. Production Techniques Different manufacturing techniques can influence the final cost of HDPE pipes. Methods that provide better performance or increased efficiency often come with a higher price.

4. Market Demand Prices can also fluctuate based on the overall demand for HDPE pipes. Periods of high demand may drive prices up, while lower demand can lead to competitive pricing strategies.

5. Supplier Location and Logistics The geographical location of suppliers and the shipping costs associated with transporting pipes can further impact prices. Suppliers closer to major construction sites may offer better pricing due to reduced logistics costs.

6. Regulatory Factors Compliance with local and international standards for quality and safety can affect pricing, as manufacturers may need to invest in certifications and quality control processes.

Conclusion

In conclusion, HDPE pipes are widely used across various sectors due to their exceptional features and durability. In China, the availability of different sizes allows for diverse applications while offering competitive pricing influenced by material quality, size, production techniques, market demand, and logistical factors. For those looking to purchase HDPE pipes, understanding these elements is crucial in making informed decisions that best meet their project requirements. As the market continues to evolve, staying updated on the latest pricing trends and product developments will be essential for consumers and industry professionals alike.

-

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

NewsAug.10,2025

-

140mm PVC Drilling Pipe: Durable & Efficient Well Casings

NewsAug.09,2025

-

Flexible DN50 HDPE Pipes in Coils: Durable & Easy Install

NewsAug.08,2025

-

DN100 PVC Pipes for Well Casings | Durable & Corrosion-Proof

NewsAug.07,2025

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025