Oct . 31, 2024 16:08 Back to list

Connecting 4% HDPE to PVC Couplings for Efficient Plumbing Solutions

Transitioning from 4% HDPE to PVC Coupling A Practical Approach

In various industries, the selection of materials for plumbing and piping systems plays a crucial role in ensuring efficiency, durability, and cost-effectiveness. High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) are two materials that are often considered when designing piping systems. The transition from a 4% HDPE to PVC coupling service is not only a technical adjustment but also one that can offer multiple benefits when executed properly.

Transitioning from 4% HDPE to PVC Coupling A Practical Approach

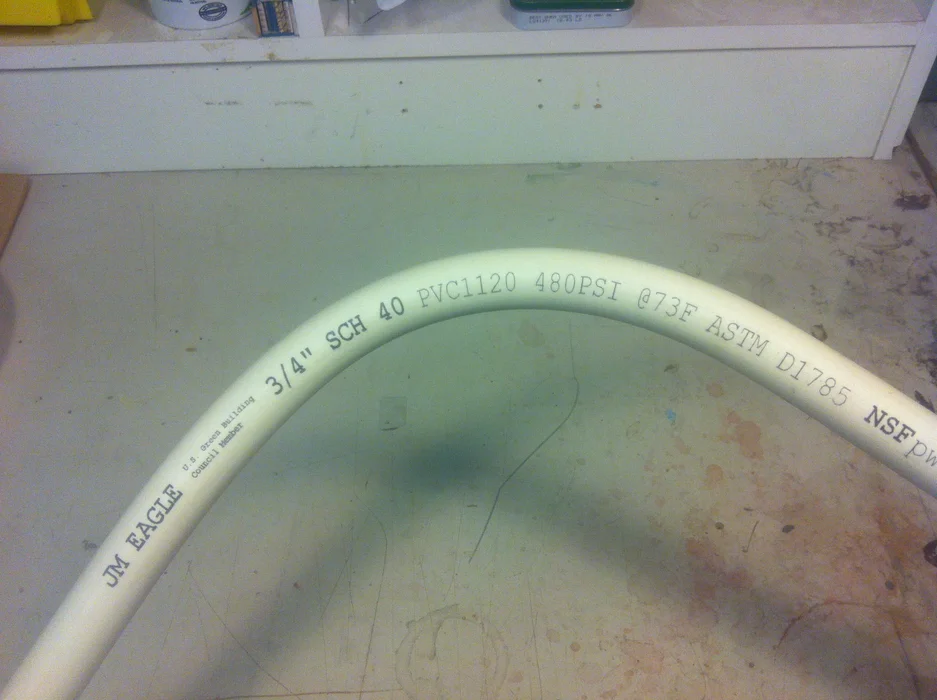

PVC, on the other hand, provides superior strength and is highly resistant to environmental stressors, including heat and chemicals found in wastewater. It is lightweight and easier to install, significantly reducing labor costs during installation. When considering a coupling service, transitioning from a 4% HDPE to a PVC coupling can provide several advantages.

4 hdpe to pvc coupling service

One of the main benefits of using PVC couplings is their compatibility with a wide range of fittings and existing piping systems. PVC couplings are designed with standardized sizing, which simplifies integration into various pipeline setups. This adaptability is particularly beneficial in retrofit or upgrade scenarios where existing HDPE pipes need to be connected to new PVC lines.

Moreover, PVC's rigidity and dimensional stability allow for efficient transport and installation. While HDPE pipes may expand and contract with temperature changes, PVC remains stable, ensuring a reliable connection over time. When dealing with fluctuating environmental conditions, this stability can translate into fewer maintenance issues and a longer lifespan for the overall piping system.

Another important factor to consider is the cost. The transition from 4% HDPE to PVC coupling may result in lower long-term expenses owing to reduced maintenance and longer durability. As PVC has a longer track record in certain applications, it can offer peace of mind regarding performance and reliability.

In conclusion, while both HDPE and PVC have their respective advantages, the shift from a 4% HDPE to PVC coupling service can bring about enhanced compatibility, rigidity, and cost savings. By evaluating the specific requirements of your application, whether it be for residential, commercial, or industrial use, one can make an informed decision that ultimately leads to a more efficient and effective piping solution. The transition, though technical, is a step towards optimizing functionality and ensuring durable connections in any piping system.

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025

-

Flexible 32mm HDPE Pipes in Coil | Durable Water & Gas Lines

NewsAug.12,2025

-

DN50 HDPE Pipes in Coils: Flexible, Durable & Easy Install

NewsAug.11,2025

-

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

NewsAug.10,2025