Blog

-

HDPE AND DI PIPE - DIFFERENCES THAT MATTER - A COMPARATIVE NARRATIVE

High-Density Polyethylene (HDPE) is made from ethylene, which is derived from petroleum and natural gas. In order to form HDPE pipe, ethylene in pellet form is melted into a molding machine and then extruded into its finished pipe form. Little, if any, true recycling is involved with HDPE products manufactured for the water and sewer industry.Conversely, Ductile iron pipe (DI pipe) is created from ferric scrap metal typically containing greater than 98 percent recycled content. Primarily consisting of recycled automobiles, the renewable ingredient stream of DI pipe is at the core of its gold-rated SMaRT© certification as a sustainable product safe for public health and the environment.Read more -

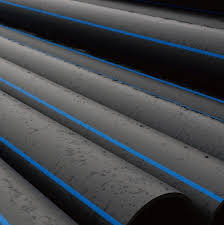

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code.In 2007, the global HDPE market reached a volume of more than 30 million tons.Read more

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code.In 2007, the global HDPE market reached a volume of more than 30 million tons.Read more -

What is HDPE Pipe, and Why is it the Best Choice for Your Pipe System?

HDPE stands for high-density polyethylene pipe, a plastic material with many benefits over traditional materials such as PVC, copper, or galvanized steel pipes.HDPE pipe is strong, durable, flexible, and lightweight, making it an ideal choice for many piping applications.It is made from a thermoplastic polymer that has a high strength-to-weight ratio. This makes it easy to transport and install in difficult places. Such as under foundations or on the side of buildings.It’s also corrosion-resistant, meaning it won’t corrode or rust due to various external factors. HDPE pipes are also ideal for use in areas where water quality is an issue, as they’re resistant to chemicals and contaminants.Read more -

HDPE pipe is a type of plastic pipe that’s used to transfer fluids and gases or to replace ageing concrete or steel mains pipelines. HDPE pipe (which stands for high-density polyethylene pipe) is flexible, highly impermeable, and suitable for high pressure pipelines. Most commonly, HDPE pipe can be seen in use for water mains, gas mains, sewer mains, slurry transfer lines, rural irrigation, fire system supply lines, electrical conduits, communication conduits and drainage pipes.Read more

HDPE pipe is a type of plastic pipe that’s used to transfer fluids and gases or to replace ageing concrete or steel mains pipelines. HDPE pipe (which stands for high-density polyethylene pipe) is flexible, highly impermeable, and suitable for high pressure pipelines. Most commonly, HDPE pipe can be seen in use for water mains, gas mains, sewer mains, slurry transfer lines, rural irrigation, fire system supply lines, electrical conduits, communication conduits and drainage pipes.Read more -

7 Ways to Identify the Quality of HDPE Pipe

HDPE pipe, also known as High Density Polyethylene Pipe, is a strong, flexible piping system that is the ideal piping material of choice for many applications including fluid and gas transportation around the world. Polyethylene’s toughness, corrosion resistance, excellent chemical resistance, and light weight allow it to provide long-term, cost-effective piping systems.Unlike decades past, today more and more companies are choosing HDPE pipe fittings because of their affordability and efficiency. Users recognize the environmentally friendly nature of HDPE pipes and thus apply it as a green solution.Read more -

What is HDPE Piping & its Benefits

High-density polyethylene (HDPE) piping is a type of plastic piping that has become increasingly popular in recent years due to its many benefits. HDPE pipes are used in a wide range of applications, from gas distribution to industrial piping systems.HDPE piping is a type of plastic piping used for carrying fluids under pressure. The pipe is lightweight, corrosion-resistant, impact-resistant, and abrasion-resistant. It can be designed to withstand high temperatures and pressures. HDPE pipe installation has become a choice in the petroleum industries because of its durability and resistance to harsh chemicals. Read to know more about HDPE piping and benefits of HDPE Pipe in detail.Read more -

HDPE Pipe: how the High-Density Polyethylene (HDPE) pipe is leading the pack

HDPE is a high-density polyethylene pipe. HDPE is one of the toughest and most durable choices for a pipe material used for utility construction today. HDPE is currently used for a variety of applications. Through this article, we will show you what makes an HDPE pipe so ideal for municipal usages, such as water, and also for industrial applications. We will focus on the benefits of an HDPE pipe as well as its applications. An HDPE pipe has been groundbreaking for the safety of underground utility delivery systems today, like municipal water, as it does not add chemicals to the water source. This innovation and many more are why HDPE pipe applications are leading the market today.Read more -

All About HDPE Pipes for Municipal Water/Sewer Systems

High-density polyethylene (HDPE) is a popular choice for municipal piping systems and its popularity only keeps on growing. This is thanks to the numerous benefits that HDPE pipes bring in a wide range of municipal and industrial applications.In this article, Blair Supply Corp, one of the most reputable companies in the utility distribution industry, shares valuable information on the use of HDPE pipes in municipal water systems. Feel free to browse our selection of quality HDPE pipes, top-notch Ford repair clamps, Smith-Blair couplings, and other utility distribution equipment for sale or keep on reading to learn all about HDPE for piping.Read more -

Pipelines are vital in providing essential water and wastewater services to the public and represent a significant investment. However, trillions of gallons of water are lost annually, with a substantial portion of the loss caused by undetected leaks from irrigation systems (1). Adopting pipelines with improved joints can significantly reduce these leaks.High-density polyethylene (HDPE) pipes are an innovative agricultural application solution, including irrigation, drainage, waste management, and livestock watering systems (2). These pipes and fittings offer various benefits, such as flexibility and a long lifespan (3, 4), and provide significantly improved leakage protection thanks to their heat-fused joints (5). Given these benefits, HDPE pipes are an attractive option for piping systems that feed into irrigation systems.Read more

Pipelines are vital in providing essential water and wastewater services to the public and represent a significant investment. However, trillions of gallons of water are lost annually, with a substantial portion of the loss caused by undetected leaks from irrigation systems (1). Adopting pipelines with improved joints can significantly reduce these leaks.High-density polyethylene (HDPE) pipes are an innovative agricultural application solution, including irrigation, drainage, waste management, and livestock watering systems (2). These pipes and fittings offer various benefits, such as flexibility and a long lifespan (3, 4), and provide significantly improved leakage protection thanks to their heat-fused joints (5). Given these benefits, HDPE pipes are an attractive option for piping systems that feed into irrigation systems.Read more -

The HDPE this unique piping is made of is a thermoplastic of the polyethylene variety, which is made from petroleum. Of the three polyethylene resins, it is the most widely used due to its flexibility and high tensile strength.Known for being a very versatile and processable resin that is inexpensive and recyclable, its usage has spiked in many industries. In fact, it is one of the most often used plastics in business today. However, even though it was discovered in 1898, production didn’t take off until the 1950s. By then, improvement in the manufacturing process made production more efficient and less costly.Naturally, this made mass production at an affordable rate a reality and therefore more HDPE found its way into everyday items. HDPE has an amazingly simple, no-frills chemical structure compared to other plastics, making it easy to process into different end products. It can be found in packaging and prescription drug bottles, building sheath, and of course, HDPE pipe to name a few applications.Read more

The HDPE this unique piping is made of is a thermoplastic of the polyethylene variety, which is made from petroleum. Of the three polyethylene resins, it is the most widely used due to its flexibility and high tensile strength.Known for being a very versatile and processable resin that is inexpensive and recyclable, its usage has spiked in many industries. In fact, it is one of the most often used plastics in business today. However, even though it was discovered in 1898, production didn’t take off until the 1950s. By then, improvement in the manufacturing process made production more efficient and less costly.Naturally, this made mass production at an affordable rate a reality and therefore more HDPE found its way into everyday items. HDPE has an amazingly simple, no-frills chemical structure compared to other plastics, making it easy to process into different end products. It can be found in packaging and prescription drug bottles, building sheath, and of course, HDPE pipe to name a few applications.Read more -

Everything you need to know about HDPE pipes: Features and Applications

The HDPE, or high density polyethylene, is a synthetic polymer made from petroleum which is commonly used in production of plastic bottles, water pipes, corrosion resistant piping, and more. Known for high density and large strength, HDPE pipes enjoy average life span of more than 50 years. High density polyethylene can be found in objects as common as containers, bottles, helmets, toys, cosmetics and all popular forms of domestic objects. Being non-toxic, odourless and insipid, HDPE boats a higher volume of production throughout the world. There are numerous HDPE pipes manufacturers around the world but you need to find the reliable ones to gain maximum benefits from HDPE pipes.Read more -

HDPE pipes consisting of flexible thermoplastic polymers are commonly used for the transport of fluids and gases at lower temperatures. In recent times, HDPE pipes have been extensively utilised for the conveyance of potable water, hazardous substances, various gases, slurry, stormwater, firewater, and more. The strength of HDPE pipe materials, characterised by robust covalent bonds, makes them well-suited for high-pressure pipeline applications. Polyethylene pipes have an extended service life in industries such as oil, gas, mining, and water. Due to its high corrosion resistance and low weight, the HDPE pipe industry is growing enormously.Erhard Holzkamp and Karl Ziegler discovered high-density polyethylene (HDPE) in 1953. These HDPE pipes can operate successfully in a large temperature span ranging from 2200 F to +1800 F. However, HDPE pipes cannot be used if the fluid temperature exceeds 1220 F (500 C).Read more

HDPE pipes consisting of flexible thermoplastic polymers are commonly used for the transport of fluids and gases at lower temperatures. In recent times, HDPE pipes have been extensively utilised for the conveyance of potable water, hazardous substances, various gases, slurry, stormwater, firewater, and more. The strength of HDPE pipe materials, characterised by robust covalent bonds, makes them well-suited for high-pressure pipeline applications. Polyethylene pipes have an extended service life in industries such as oil, gas, mining, and water. Due to its high corrosion resistance and low weight, the HDPE pipe industry is growing enormously.Erhard Holzkamp and Karl Ziegler discovered high-density polyethylene (HDPE) in 1953. These HDPE pipes can operate successfully in a large temperature span ranging from 2200 F to +1800 F. However, HDPE pipes cannot be used if the fluid temperature exceeds 1220 F (500 C).Read more