Blog

-

Which Is Better HDPE Or PPR Pipe?

When it comes to selecting pipe materials for water supply systems, there are various types available in the market. The two most commonly used pipe materials are High-density Polyethylene (HDPE) and Polypropylene Random Copolymer (PPR). Both materials are widely used in different industries for their unique properties. In this article, we will compare HDPE and PPR pipes and explore which is better for use in water supply systems based on their properties, installation procedures, and user requirements.Read more -

What Are PPR Pipes and Fittings?

PPR fittings are made from the same material as PPR pipes, which means they are also resistant to temperature changes, UV radiation, and chemical degradation. They are easy to install and require no special tools or equipment, making them a popular choice for plumbing and heating systems.Read more -

PPR pipes, also known as polypropylene random copolymer pipes, have been gaining popularity in various industries due to their durability, ecological benefits, and economic efficiency. These pipes are commonly used in home installations, water supply systems, hot water pipe systems, heating pipe systems, and air conditioning pipe systems. In this comprehensive guide, we will explore everything you need to know about PPR pipes, including their characteristics, main uses, advantages, and installation process.Read more

PPR pipes, also known as polypropylene random copolymer pipes, have been gaining popularity in various industries due to their durability, ecological benefits, and economic efficiency. These pipes are commonly used in home installations, water supply systems, hot water pipe systems, heating pipe systems, and air conditioning pipe systems. In this comprehensive guide, we will explore everything you need to know about PPR pipes, including their characteristics, main uses, advantages, and installation process.Read more -

What are the Main Uses of PPR Pipe?

PPR Pipe has been growing in popularity over the last couple of years, and rightly so. Its durability, ecological, and economic benefits make PPR pipes one of the best in the industry. That is why most industry leaders have turned to PPR pipes for all their needs.PPR pipes are commonly used in home installations. It is also used in sanitary liquid, alkaline and acidic solutions, compressed air, and transferring water. But what exactly is PPR pipe, and how is it used? We have prepared this comprehensive guide to help you learn everything about PPR pipes.Read more -

PPR pipes are an excellent choice for plumbing and water supply applications. They are durable, cost-effective, and easy to install, making them a popular choice for both residential and commercial applications. They are also environmentally friendly, hygienic, and resistant to chemicals and bacteria, which makes them a safe and reliable choice for a wide range of applications.Read more

PPR pipes are an excellent choice for plumbing and water supply applications. They are durable, cost-effective, and easy to install, making them a popular choice for both residential and commercial applications. They are also environmentally friendly, hygienic, and resistant to chemicals and bacteria, which makes them a safe and reliable choice for a wide range of applications.Read more -

PPR pipe as a common pipeline water supply system is widely used in various construction industries, including residential domestic piping systems, hotels and shopping mall plumbing projects, etc...So how much do you know the PPR pipe you are using? How do you select the best PPR pipe or fitting for your project? Through this article, let get to know about PPR pipe!Read more

PPR pipe as a common pipeline water supply system is widely used in various construction industries, including residential domestic piping systems, hotels and shopping mall plumbing projects, etc...So how much do you know the PPR pipe you are using? How do you select the best PPR pipe or fitting for your project? Through this article, let get to know about PPR pipe!Read more -

A PPR pipe is a form of plastic pipe made from a material known as polypropylene random copolymer plastic. The material is similar to that used in the manufacturing of water supply materials for household purposes, but it can be used to provide hot and cold drinking water as well as for heating systems. It was first launched in France in 1962 by its trade name ‘Plastic Pipe Revolvy.’Read more

A PPR pipe is a form of plastic pipe made from a material known as polypropylene random copolymer plastic. The material is similar to that used in the manufacturing of water supply materials for household purposes, but it can be used to provide hot and cold drinking water as well as for heating systems. It was first launched in France in 1962 by its trade name ‘Plastic Pipe Revolvy.’Read more -

What is PPR Pipe & What is it Used For?

Since its development in the early 90’s the application of PPR pipe has become commonplace, due to its durability, cost effectiveness and long service life. As a manufacturer you may be curious as to why some companies choose to produce PPR over PVC and PE pipe. In this article we will cover the basics of PPR pipe, its features, advantages, and its most common applications.Read more -

PPR pipe is a copolymer made of propylene monomer and ethylene monomer and is one of the most energy-saving and environmentally friendly plastic pipe products. As an emerging material, PPR pipes must have advantages and disadvantages. This post will take you through the advantages and disadvantages of PPR pipes.Read more

PPR pipe is a copolymer made of propylene monomer and ethylene monomer and is one of the most energy-saving and environmentally friendly plastic pipe products. As an emerging material, PPR pipes must have advantages and disadvantages. This post will take you through the advantages and disadvantages of PPR pipes.Read more -

Which Pipe is Safe for You – PPR or CPVC?

Before going into the specification let’s make ourselves clear what each material is made up of. PPR is the short-form for Polypropylene Random Copolymer while CPVC is Chlorinated Polyvinyl Chloride is produced by a process of chlorination to Polyvinyl Chloride.PPR is the most widely used plumbing piping system in Europe, Russia, South America, Africa, South Asia, China and Middle East while CPVC is used mainly in India and Mexico. PPR is superior to CPVC not because of wide acceptability but also it is safe for potable water.Now, let’s help you make a safer decision as to why CPVC Pipes are not safe and why you should prefer PPR Pipes.Read more -

What is the difference between PPR pipe and PVC pipe?

The main material of PPR pipe is copolymerized polypropylene, so PPR pipe is also called three-type polypropylene pipe, while PVC is made of polyvinyl chloride material. The two kinds of pipes have different performance characteristics due to different main raw materials. It is also because of the raw materials that PPR pipes are mostly hot-melted during installation, and PVC pipes are mostly glued.Read more -

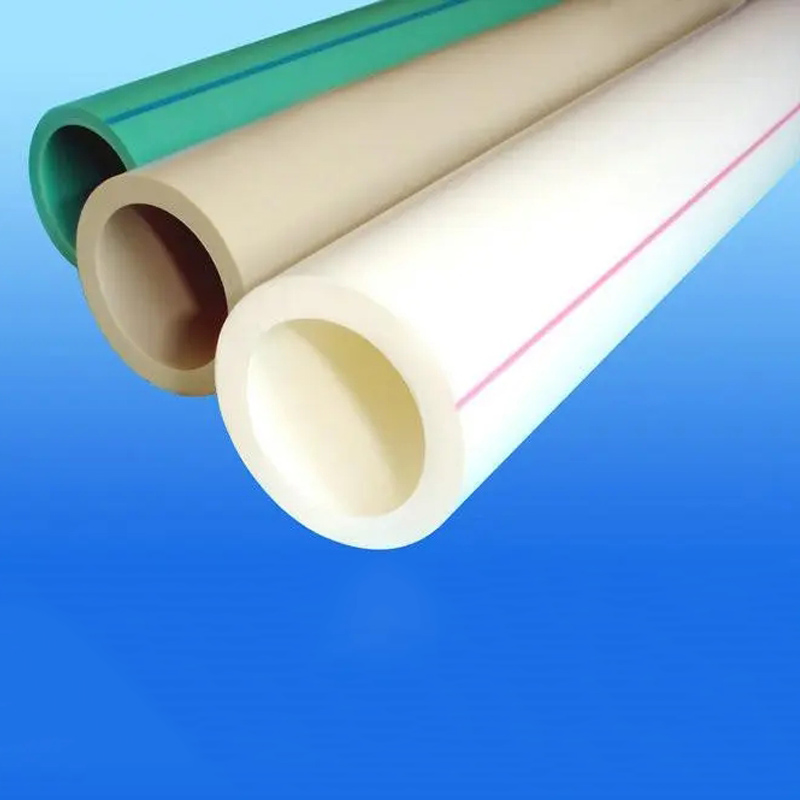

WHAT ARE PPR PIPES? FEATURES AND APPLICATIONS

PPR pipes (Polypropylene Random Copolymer pipes) are a type of plastic pipe made from a blend of polypropylene and ethylene copolymers. PPR is a high-technology plastic pipe, which is modern plumbing’s important solution when matched to cold galvanized pipes for all hot water systems. PPR Pipe and fittings are made with high-grade raw materials. It is one of the essential plastic pipe products which are used for extreme tempratures ranging from -20°C to 95°C. Mostly these pipes are green or white in color.These Pipes are made with a variety of fittings, accessories, and replacement components and each pipe diameter has its own set of attachments.Read more