Blog

-

A PPR pipe is a form of plastic pipe made from a material known as polypropylene random copolymer plastic. The material is similar to that used in the manufacturing of water supply materials for household purposes, but it can be used to provide hot and cold drinking water as well as for heating systems. It was first launched in France in 1962 by its trade name ‘Plastic Pipe Revolvy.’Read more

A PPR pipe is a form of plastic pipe made from a material known as polypropylene random copolymer plastic. The material is similar to that used in the manufacturing of water supply materials for household purposes, but it can be used to provide hot and cold drinking water as well as for heating systems. It was first launched in France in 1962 by its trade name ‘Plastic Pipe Revolvy.’Read more -

What is PPR Pipe & What is it Used For?

Since its development in the early 90’s the application of PPR pipe has become commonplace, due to its durability, cost effectiveness and long service life. As a manufacturer you may be curious as to why some companies choose to produce PPR over PVC and PE pipe. In this article we will cover the basics of PPR pipe, its features, advantages, and its most common applications.Read more -

PPR pipe is a copolymer made of propylene monomer and ethylene monomer and is one of the most energy-saving and environmentally friendly plastic pipe products. As an emerging material, PPR pipes must have advantages and disadvantages. This post will take you through the advantages and disadvantages of PPR pipes.Read more

PPR pipe is a copolymer made of propylene monomer and ethylene monomer and is one of the most energy-saving and environmentally friendly plastic pipe products. As an emerging material, PPR pipes must have advantages and disadvantages. This post will take you through the advantages and disadvantages of PPR pipes.Read more -

Which Pipe is Safe for You – PPR or CPVC?

Before going into the specification let’s make ourselves clear what each material is made up of. PPR is the short-form for Polypropylene Random Copolymer while CPVC is Chlorinated Polyvinyl Chloride is produced by a process of chlorination to Polyvinyl Chloride.PPR is the most widely used plumbing piping system in Europe, Russia, South America, Africa, South Asia, China and Middle East while CPVC is used mainly in India and Mexico. PPR is superior to CPVC not because of wide acceptability but also it is safe for potable water.Now, let’s help you make a safer decision as to why CPVC Pipes are not safe and why you should prefer PPR Pipes.Read more -

What is the difference between PPR pipe and PVC pipe?

The main material of PPR pipe is copolymerized polypropylene, so PPR pipe is also called three-type polypropylene pipe, while PVC is made of polyvinyl chloride material. The two kinds of pipes have different performance characteristics due to different main raw materials. It is also because of the raw materials that PPR pipes are mostly hot-melted during installation, and PVC pipes are mostly glued.Read more -

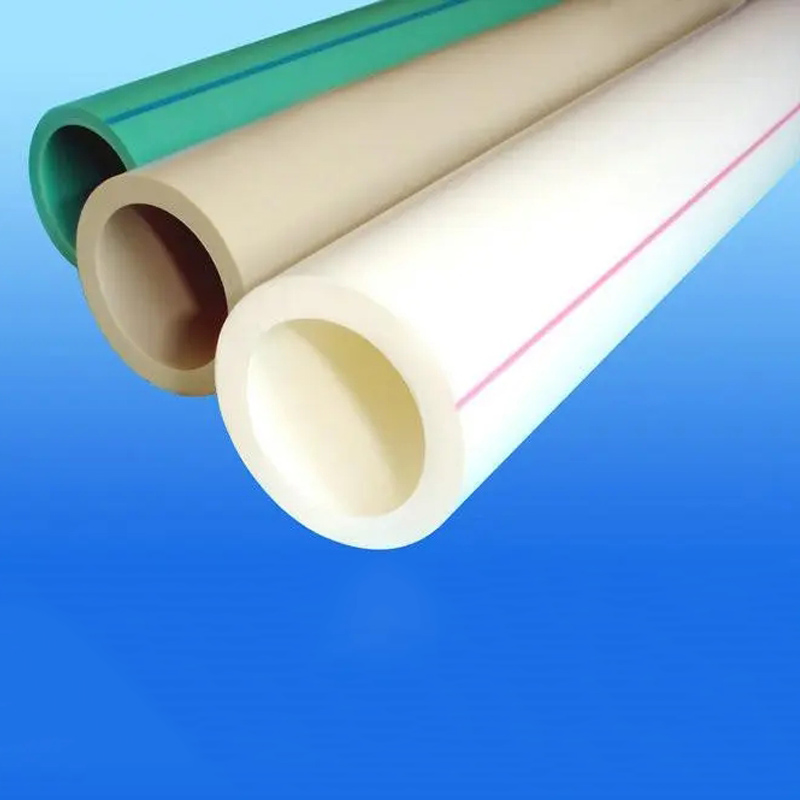

WHAT ARE PPR PIPES? FEATURES AND APPLICATIONS

PPR pipes (Polypropylene Random Copolymer pipes) are a type of plastic pipe made from a blend of polypropylene and ethylene copolymers. PPR is a high-technology plastic pipe, which is modern plumbing’s important solution when matched to cold galvanized pipes for all hot water systems. PPR Pipe and fittings are made with high-grade raw materials. It is one of the essential plastic pipe products which are used for extreme tempratures ranging from -20°C to 95°C. Mostly these pipes are green or white in color.These Pipes are made with a variety of fittings, accessories, and replacement components and each pipe diameter has its own set of attachments.Read more -

Large Diameter HDPE Pipe – What’s the big deal?

Large diameter pipe has been around for a while. It’s not new technology.There is however a perception that large diameter HDPE is the smart phone of the telephone family.While HDPE does have numerous advantages that mirror the value of having an iPhone, the perceived youth of large diameter has a narrow world view to blame.Large diameter HDPE pipe is relatively new in its usage in North America. Countries overseas have been utilizing it for much longer. The cost of shipping large diameter HDPE pipe has made it difficult to justify it as a viable option, so it wasn’t until the pipe was manufactured domestically that the perception began to change.And change it did.Read more -

Polyethylene piping’s performance in mining, dredging and similar applications proves it will outwear many more costly piping materials when conveying a variety of abrasive slurries. HDPE has excellent corrosion resistance and is virtually inert. It does not need expensive maintenance or cathodic protection. It offers better overall resistance to corrosive acids, bases and salts than most piping materials. In addition, polyethylene is unaffected by bacteria, fungi and the most “aggressive” naturally occurring soils. It has good resistance to many organic substances, such as solvents and fuels.Read more

Polyethylene piping’s performance in mining, dredging and similar applications proves it will outwear many more costly piping materials when conveying a variety of abrasive slurries. HDPE has excellent corrosion resistance and is virtually inert. It does not need expensive maintenance or cathodic protection. It offers better overall resistance to corrosive acids, bases and salts than most piping materials. In addition, polyethylene is unaffected by bacteria, fungi and the most “aggressive” naturally occurring soils. It has good resistance to many organic substances, such as solvents and fuels.Read more -

Common Uses of High-Density Polyethylene

High-density polyethylene or HDPE is a commonly used petroleum thermoplastic and the most used of the three polyethylenes for a wide range of applications. If you look at this plastic under a microscope, you would see that it has a linear structure with few branches lending to its optimal strength/density ratio. As a result of its molecular makeup, this polymer shines brightest in applications where moisture resistance and cost-effectiveness are needed.HDPE was created in the 1930s and used in high-frequency radar cables during World War II. It was introduced to the market commercially soon after. While its higher density versions yield a more rigid result, HDPE can vary in flexibility. Low-density grades of the thermoplastic are less stiff and the high-density grades have equally high crystallinity.Read more -

Is HDPE pipe safe for Drinking Water?

Rapid Response Question: Metal pipe and plumbing materials have historically had issues with corrosion, sediment build-up, pressure resistance, thermal conductivity, and chemical resistance. Cross-linked polyethylene (PEX) piping is one alternative, but the available sizes are too small for major commercial installations.Read more -

All You Need To Know About HDPE Pipes

Synthetic petroleum polymers, such as HDPE, are utilized in the manufacturing of plastic bottles and water pipes and corrosion-resistant pipework. HDPE pipes have an average lifespan of more than 50 years because of their high density and huge strength. A lot of regular items are made of high-density polyethylene, such as containers, bottles, helmets, toys, and cosmetics. HDPE's non-toxic, odorless, and insipid qualities have made it a popular choice across the globe.Read more -

HDPE Pipe for Hassle-Free Installation

AdaptabilityPE has the ability to be easily modified on site. Cutting and jointing can be carried out in final positions using butt, electro-fusion or manual welding processes with the results being instant. No curing time is required, providing watertight seals.Safe for Drinking WaterAs HDPE pipes are made of food-grade material, they are safe to transfer drinking water. Furthermore, they can maintain the fluid temperature more than other pipes; thereby preventing the need for any insulation.Read more