Aug . 11, 2024 07:28 Back to list

Top HDPE Duct Coupler Suppliers Offering High-Quality Solutions for Your Installation Needs

HDPE Duct Coupler Manufacturers An Overview

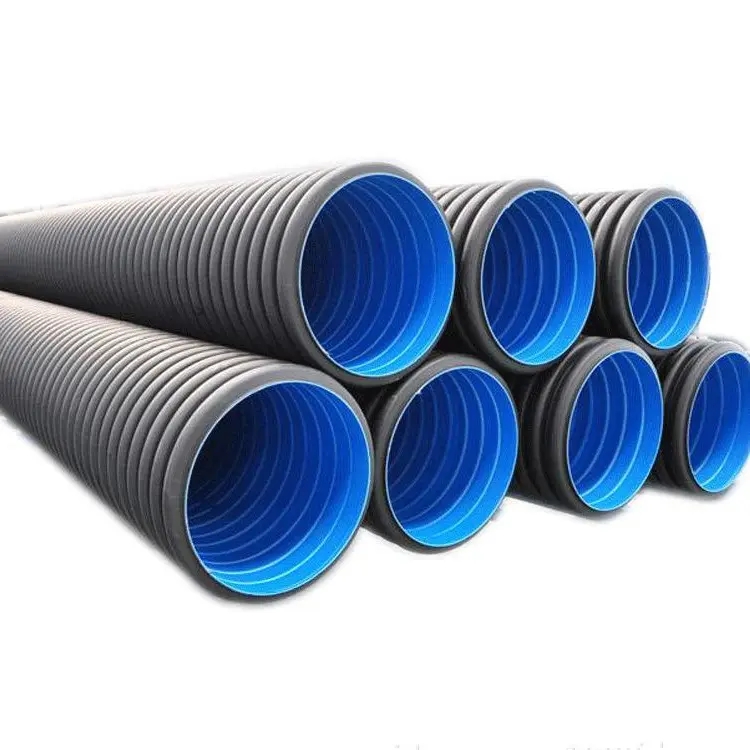

High-Density Polyethylene (HDPE) duct couplers play a vital role in the construction and telecommunications industries, providing essential connections and seals for pipeline and duct systems. The versatility of HDPE material, combined with its resistance to chemical corrosion and durability, makes it an ideal choice for various applications, including water supply, drainage systems, and telecom installations. As the demand for HDPE duct systems continues to grow, manufacturers of HDPE duct couplers are increasingly meeting the needs of the market with innovative and reliable solutions.

The Importance of HDPE Duct Couplers

Duct couplers serve the critical function of connecting two sections of duct, ensuring that the system operates efficiently and preventing leaks or failures in the connection points. They must withstand extreme environmental conditions while maintaining the integrity of the overall system. With the ability to adapt to different sizes and configurations, HDPE duct couplers provide a flexible solution for projects of varying scales—ranging from small residential installations to large industrial setups.

One of the key advantages of HDPE duct couplers is their lightweight nature combined with high strength, making them easy to handle and install. This ease of transportation and installation can significantly decrease labor costs and project timelines. Furthermore, HDPE's resistance to UV radiation, moisture, and certain chemicals enhances its longevity, making it a cost-effective option for long-term applications.

Choosing the Right Manufacturer

When selecting a manufacturer for HDPE duct couplers, several factors must be considered to ensure quality and compatibility with project specifications

. Here are some essential criteria for choosing the right manufacturer1. Experience and Reputation Established manufacturers with a proven history in producing HDPE products typically have more refined processes and quality control measures. Researching customer reviews and industry feedback can provide valuable insights into a manufacturer's reputation.

hdpe duct coupler manufacturers

2. Quality Assurance It is crucial that the manufacturer adheres to strict quality control standards. Certifications from recognized organizations, such as ISO or ASTM, can indicate that the manufacturer meets industry standards for durability and performance.

3. Materials and Technology Understanding the materials used in production is vital. Quality manufacturers will utilize high-grade HDPE that complies with relevant regulations. Additionally, manufacturers incorporating advanced production techniques and technology can offer more innovative solutions and improve the performance of their couplers.

4. Product Range and Customization A manufacturer that offers a diverse range of products can better meet unique project requirements. Some manufacturers may also provide customization options, allowing for tailored solutions that fit specific applications.

5. Customer Support and Service Effective customer support is essential for addressing any issues that may arise during the installation or use of HDPE duct couplers. Manufacturers that prioritize customer service, providing technical assistance and reliable post-sales support, can foster better long-term partnerships.

The Future of HDPE Duct Coupler Manufacturing

As industries evolve, so too do the needs for efficient and sustainable solutions in pipeline and duct systems. Manufacturers of HDPE duct couplers are continuously innovating to meet these demands. Emerging trends include the integration of smart technologies that enhance monitoring and maintenance capabilities, as well as sustainability initiatives focusing on reducing waste and promoting recycled materials in manufacturing processes.

Moreover, with the increasing focus on infrastructure development and telecommunications expansion, the market for HDPE duct couplers is poised for growth. Manufacturers must stay ahead of industry trends, invest in research and development, and collaborate with stakeholders to deliver cutting-edge solutions that address the challenges of modern construction and utilities management.

In conclusion, HDPE duct coupler manufacturers play a crucial role in the efficiency and reliability of duct and pipeline systems. By focusing on quality, innovation, and customer satisfaction, these manufacturers can effectively contribute to the evolving landscape of infrastructure and utility services.

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025

-

Flexible 32mm HDPE Pipes in Coil | Durable Water & Gas Lines

NewsAug.12,2025

-

DN50 HDPE Pipes in Coils: Flexible, Durable & Easy Install

NewsAug.11,2025