Nov . 06, 2024 10:17 Back to list

Connecting PVC Pipes to HDPE Pipes for Efficient Water Management Solutions

Connecting PVC and HDPE Pipes A Comprehensive Guide

In modern plumbing and construction, the choice of materials is crucial for ensuring efficiency, durability, and cost-effectiveness. Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE) pipes are two popular options that serve various applications across industry sectors. Although these materials possess unique properties, there are situations where professionals must connect PVC pipes to HDPE pipes. This article provides an overview of the best practices for establishing a reliable connection between PVC and HDPE, along with the advantages and challenges of using these materials.

Understanding PVC and HDPE

PVC pipes are widely known for their rigidity, chemical resistance, and durability. They are commonly used in water supply systems, drainage, and sewage applications. On the other hand, HDPE pipes are recognized for their flexibility, light weight, and resistance to corrosion. They are often used in applications requiring extensive bending, such as in mining, gas distribution, and telecommunications.

The Importance of Proper Connection

Connecting PVC and HDPE pipes can sometimes be necessary due to availability, cost considerations, or specific project requirements. However, improper connections might lead to leaks, failures, and costly repairs. Therefore, understanding the right methods and products is vital for ensuring a successful connection.

Methods for Connecting PVC to HDPE

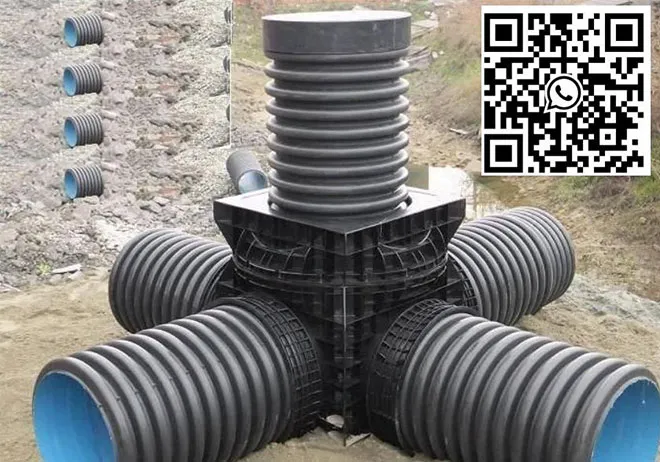

1. Mechanical Couplings One of the most common methods for joining PVC to HDPE is through mechanical couplings. These couplings can accommodate differences in the diameters and material properties of both types of pipes. When using mechanical couplings, it is essential to ensure that the fittings are compatible with both PVC and HDPE materials to provide a secure seal.

2. Transition Fittings Transition fittings specifically designed for joining different materials are another effective solution. These fittings typically have one end designed to fit PVC and the other for HDPE. It is crucial to choose transition fittings that meet industry standards and are suitable for the intended application.

pvc to hdpe pipe connection product

3. Glue and Adhesives While glue is often used for PVC pipe connections, it is generally not recommended for HDPE due to its non-porous nature. However, specialized adhesives that bond various materials may provide a viable solution in specific scenarios. Always follow the manufacturer's guidelines and ensure that the adhesive is suitable for both types of pipes.

4. Fusion Welding For HDPE, fusion welding is a common method for creating a strong, leak-free connection. However, this method is not applicable to PVC. In cases where both types of pipes need to be fused together, a suitable transition fitting should be installed to facilitate proper connection.

Challenges and Considerations

While connecting PVC and HDPE pipes can be accomplished effectively, several challenges must be considered

- Thermal Expansion Different rates of thermal expansion between the two materials may cause stress at the connection point. It is essential to allow flexibility in the installation to accommodate these variations.

- Pressure Ratings Ensure that the pressure rating of the connection is adequate for the intended application. Both PVC and HDPE have distinct pressure ratings, and the connection should not exceed the lower rating to ensure safety.

- Local Codes and Regulations Always check local plumbing codes and regulations regarding the use of PVC and HDPE. Compliance with these regulations is crucial for ensuring safety and preventing future complications.

Conclusion

Connecting PVC to HDPE pipes can be an essential part of modern plumbing and construction projects. By understanding the materials, methods, and challenges involved, professionals can achieve secure and efficient connections that support long-term performance. Proper adherence to industry standards and local regulations will contribute to successful projects and enhance the overall reliability of piping systems.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025