Nov . 06, 2024 10:09 Back to list

The Evolution of PVC Piping Standards: Meeting the Demands of Modern Construction

PVC (polyvinyl chloride) piping has become a cornerstone of modern construction, widely used for water distribution, sewage, and industrial applications. The evolution of PVC piping standards has played a crucial role in ensuring that these pipes meet the increasingly complex demands of contemporary construction projects. This article explores how PVC piping standards have evolved over time and how they continue to adapt to modern construction needs.

Origins of PVC Piping and Early Standards

The development of PVC piping began in the early 20th century, with its first applications emerging in Europe during the 1930s. These early pipes were valued for their durability, resistance to corrosion, and ease of installation compared to traditional materials like metal and concrete. However, as PVC piping began to gain popularity, it became clear that standardized guidelines were necessary to ensure consistent quality and performance.

The first set of standards for PVC piping was introduced in the mid-20th century, focusing primarily on basic manufacturing processes and material composition. These early standards laid the groundwork for more comprehensive guidelines, ensuring that pvc pipe used for water supply could withstand the pressures and environmental conditions typical of plumbing and industrial applications.

Advancements in Material Composition and Manufacturing of PVC Piping

As construction techniques evolved and the demand for more versatile materials grew, so too did the standards governing PVC piping. Advances in polymer chemistry during the latter half of the 20th century allowed for the development of more sophisticated PVC compounds, enhancing the material's strength, flexibility, and resistance to environmental stressors.

Modern pvc sewer pipes are now subject to stringent standards that dictate everything from the raw materials used in their production to the specific processes employed during manufacturing. These standards ensure that the pipes exhibit uniform wall thickness, proper joint integrity, and resistance to UV degradation, all of which are critical for maintaining long-term performance in various applications.

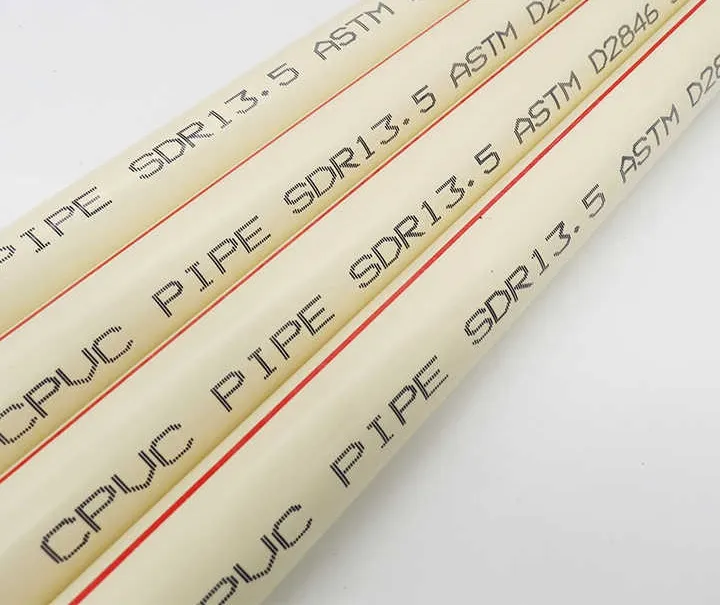

In response to the increasing complexity of construction projects, standards have also been established for specialized types of PVC pipes, such as chlorinated polyvinyl chloride (CPVC) and oriented polyvinyl chloride (PVC-O). These variants offer enhanced performance characteristics, such as higher temperature resistance and improved impact strength, making them suitable for a broader range of applications.

Meeting Environmental and Safety Regulations of PVC Piping

As environmental concerns and safety regulations have become more prominent in the construction industry, PVC piping standards have evolved to address these issues. Modern standards now include guidelines for the reduction of harmful emissions during the manufacturing process, as well as the safe disposal and recycling of PVC products.

The introduction of lead-free PVC formulations is one of the most significant advancements in response to environmental and health concerns. Lead was once a common stabilizer used in PVC production, but its toxic effects prompted a shift towards safer alternatives. Today, PVC pipes must meet rigorous lead-free standards, ensuring that they are safe for use in potable water systems and other sensitive applications.

Additionally, PVC piping standards now emphasize the importance of sustainability, encouraging the use of recycled materials and the development of more energy-efficient production methods. These efforts align with the broader goals of the construction industry to reduce its environmental footprint and promote sustainable practices.

Adapting to Modern Construction Techniques About PVC Piping

The evolution of PVC piping standards has also been driven by advancements in construction techniques and the need for materials that can keep pace with these innovations. Modern construction projects often involve complex systems that require precise coordination between various building components, including plumbing, electrical, and HVAC systems.

To meet these demands, PVC piping standards have been updated to include guidelines for installation practices that ensure compatibility with other building materials and systems. For example, standards now address the proper installation of PVC pipes in buildings with high seismic activity, where flexibility and joint integrity are critical to preventing damage.

The advent of trenchless construction methods, such as pipe bursting and directional drilling, has also influenced the evolution of PVC piping standards. These methods require pipes that can withstand the stresses of being installed without traditional open trenching, leading to the development of standards that specify enhanced durability and flexibility for PVC pipes used in these applications.

The Future of PVC Piping Standards

As the construction industry continues to evolve, so too will the standards governing PVC piping. Emerging trends, such as the increasing use of smart technology in buildings and the push towards net-zero energy construction, will likely influence future standards. For instance, the integration of sensors and other smart devices into PVC piping systems may require new guidelines to ensure compatibility and long-term performance.

Moreover, as global construction projects become more ambitious, with megacities and infrastructure projects demanding materials that can withstand extreme conditions, PVC piping standards will need to adapt to these challenges. This may involve the development of new PVC compounds with enhanced properties or the creation of standards that address specific regional requirements, such as those related to climate or seismic activity.

HORON INTERNATIONAL-Your Reliable Construction Plastic Pipes Manufacturer

Construction plastic pipes play a vital role in many of industrial fields. Only by purchasing from trustworthy manufacturers can the quality and precision be guaranteed. HORON INTERNATIONAL is a leading manufacturer of construction plastic pipes in China, With many years of industry experience and excellent reputation, is able to be come your reliable supplier. Contact us now to get more information.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025