Nov . 06, 2024 10:05 Back to list

The Impact of PVC Pipes on Water Quality: Myths and Facts

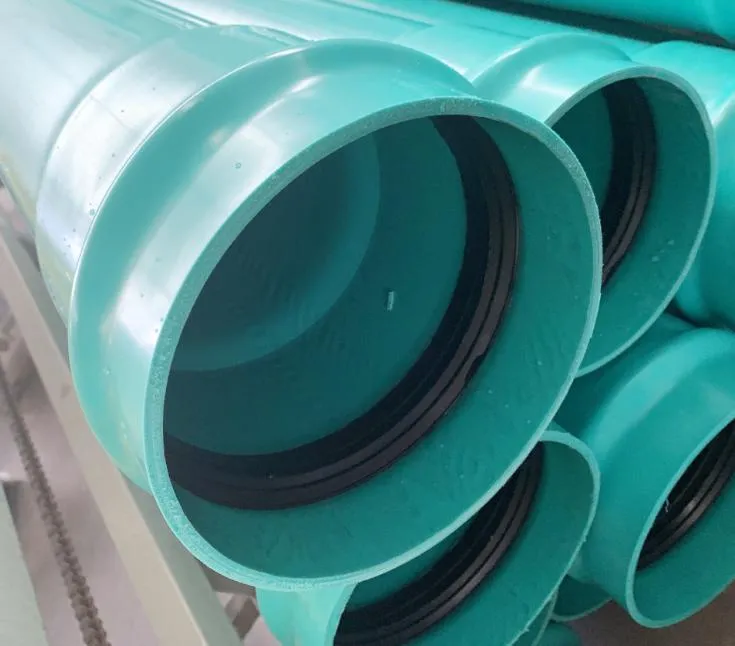

PVC (polyvinyl chloride) pipes are a common choice for water supply systems worldwide, praised for their durability, cost-effectiveness, and ease of installation. However, concerns about the potential impact of PVC pipes on water quality have led to debates and the spread of various myths. This article explores the true impact of PVC pipes on water quality, separating myths from facts to provide a clearer understanding.

Myth: PVC Pipes Release Harmful Chemicals into Drinking Water

One of the most persistent myths about pvc tubing is that they release harmful chemicals, such as vinyl chloride and phthalates, into drinking water, posing a risk to human health. While it is true that vinyl chloride, a known carcinogen, is used in the production of PVC, the finished product is stable and does not release vinyl chloride into the water.

Perforated land drainage pipes undergo rigorous testing and certification processes to ensure they meet safety standards for potable water use. These standards include limits on the amount of residual vinyl chloride and other substances that can leach into the water. Research has consistently shown that PVC pipes, when properly manufactured and installed, do not contribute harmful levels of chemicals to drinking water.

Fact: PVC Pipes Are Corrosion-Resistant and Improve Water Quality

Unlike metal pipes, which can corrode over time and release harmful substances like lead and copper into the water supply, PVC pipes are inherently resistant to corrosion. This resistance is one of the key advantages of PVC in water distribution systems, as it helps to maintain the purity of the water being transported.

Corrosion in metal pipes not only compromises water quality but also leads to pipe degradation and increased maintenance costs. By using PVC pipes, water utilities can avoid these issues, ensuring a cleaner and safer water supply with less need for chemical treatments to prevent corrosion.

Myth: PVC Pipes Affect the Taste and Odor of Water

Another common myth is that PVC pipes negatively impact the taste and odor of drinking water. Some consumers have reported a “plastic” taste or smell in their water, leading to concerns that PVC pipes might be the cause. However, these issues are often related to factors other than the pipes themselves.

For instance, new PVC pipes may have a slight odor initially due to the manufacturing process, but this dissipates quickly once the pipes are flushed and in regular use. Moreover, taste and odor issues in water can be caused by various factors, including the water source, disinfectants like chlorine, and the condition of other components in the plumbing system. Studies have shown that PVC pipes do not impart any significant taste or odor to drinking water when properly installed and maintained.

Fact: PVC Pipes Contribute to Sustainable Water Management

PVC pipes are not only safe for water quality but also contribute to sustainable water management practices. Their long lifespan—often exceeding 50 years—means that PVC pipes require less frequent replacement, reducing the environmental impact associated with manufacturing and installing new pipes.

Additionally, the smooth interior surface of PVC pipes reduces friction loss, improving the efficiency of water flow and reducing the energy required for pumping. This efficiency helps conserve energy and reduce greenhouse gas emissions, aligning with broader goals of sustainability in water management.

Furthermore, PVC is a recyclable material. When PVC pipes reach the end of their useful life, they can be recycled into new pipes or other products, further reducing their environmental footprint. This recyclability makes PVC an attractive option for water utilities and builders looking to minimize waste and promote a circular economy.

Myth: PVC Pipes Are Not Suitable for Hot Water Applications

A misconception exists that PVC pipes are unsuitable for transporting hot water due to concerns about their durability and potential for chemical leaching at higher temperatures. While it is true that standard PVC pipes are not designed for hot water applications, this issue is addressed by using CPVC (chlorinated polyvinyl chloride) pipes, which are specifically engineered to handle hot water.

CPVC pipes share many of the benefits of PVC, including corrosion resistance and a long lifespan, but they are also capable of withstanding higher temperatures without compromising water quality. For hot water distribution systems, CPVC is the recommended material, ensuring that the water remains safe for consumption while maintaining the durability of the piping system.

Fact: Regulatory Standards Ensure the Safety of PVC Pipes for Water Supply

To address concerns about water quality, PVC pipes are subject to strict regulatory standards worldwide. These standards, established by organizations such as the National Sanitation Foundation (NSF) and the American Water Works Association (AWWA), set limits on the levels of substances that can leach from pipes into drinking water.

In addition to regulatory oversight, third-party testing and certification ensure that PVC pipes used in water supply systems meet or exceed safety requirements. This rigorous process provides assurance to consumers and water utilities that PVC pipes are a safe and reliable choice for delivering clean drinking water.

HORON INTERNATIONAL-Your Reliable Construction Plastic Pipes Manufacturer

Construction plastic pipes play a vital role in many of industrial fields. Only by purchasing from trustworthy manufacturers can the quality and precision be guaranteed. HORON INTERNATIONAL is a leading manufacturer of construction plastic pipes in China, With many years of industry experience and excellent reputation, is able to be come your reliable supplier. Contact us now to get more information.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025