Jun . 24, 2024 10:19 Back to list

10 key reasons to choose PVC pipes

10 key reasons to choose PVC pipes

PVC pipes are cost-efficient

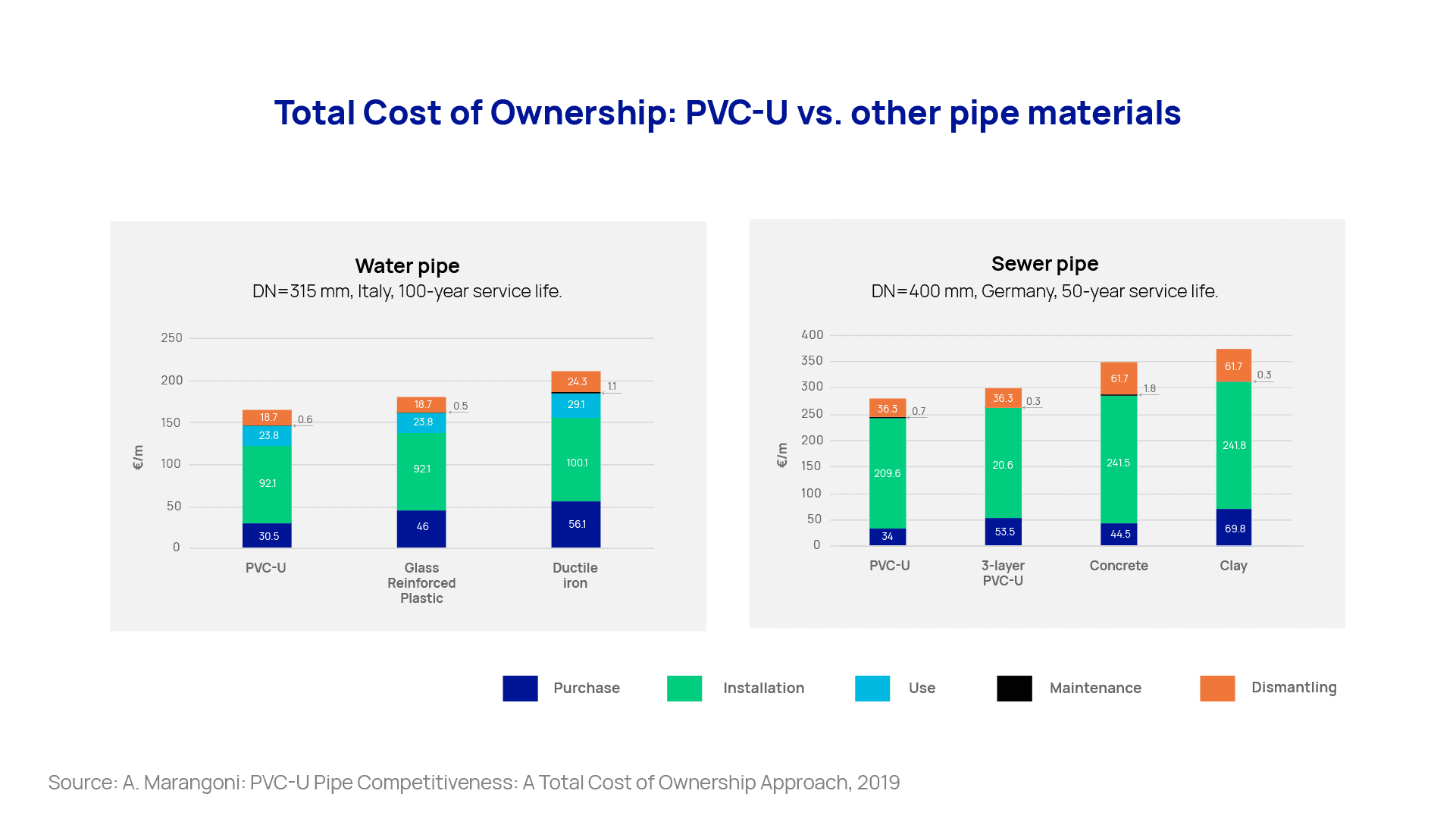

Comparative studies from several European countries document PVC water and sewer pipes have the lowest Total Cost of Ownership compared to non-plastic materials. This includes the costs to purchase pipes, install, operate and maintain and dismantle the pipeline. 100+ years of service life and low Total Cost of Ownership mean utilities can safely choose PVC for their piping infrastructure.

PVC pipes are increasingly sustainable

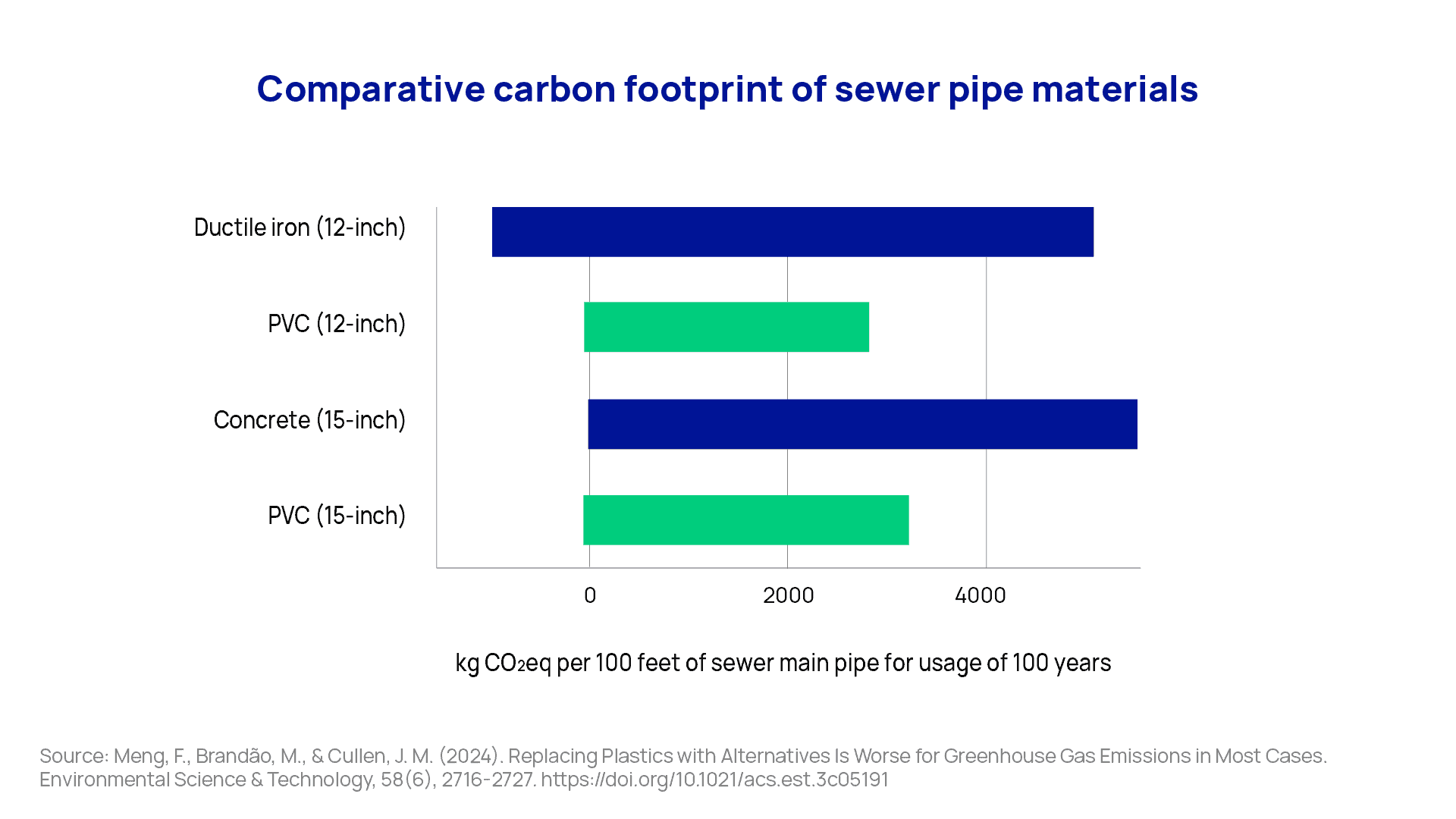

Recent peer-reviewed research and comparative Life Cycle Assessments (LCAs) underscore the significant environmental advantages of PVC pipes over traditional materials like ductile iron and concrete, particularly in terms of their carbon footprint. PVC pipes weigh less, which not only requires less energy for production but also minimises the greenhouse gas (GHG) emissions associated with transport and installation.

PVC is inherently a low carbon plastic, made from 57% chlorine derived from common salt. The high chlorine content means it consumes less primary energy than other plastics such as HDPE, LDPE, and PP.

Thanks to innovation and investments, bio-attributed and bio-circular PVC resin and non-fossil additives are available on the market and are already being used in pipes.

Long-lasting, circular, efficient

PVC pipes have a long service life, spanning 100 years or more when buried underground. Their unique molecular structure enables up to 10 cycles of mechanical recycling without significant loss of functional properties. Moreover, the ultra-smooth surface of PVC pipes reduces pumping costs and energy use, and their leak-free fittings eliminate water loss. This is good for both the environment and the utility bill.

PVC pipes are recyclable and increasingly being recycled

PVC pipes can be recycled 8 to 10 times without losing their technical properties. Each year around 50,000 tonnes of PVC pipes and fittings are recycled in Europe through the VinylPlus® programme. Since 2000 around 820,000 tonnes have been recycled. PVC pipes are also a major uptake for recycled PVC in Europe. 75,000 tonnes of recycled PVC are safely used in new pipes each year. Traceability and certification schemes for recyclates ensure a high degree of safety and quality for the recycled PVC.

PVC recycling creates jobs and saves energy and resources

Using recycled PVC helps meet resource-efficiency targets and allows the preservation of natural resources. For each kg of PVC recycled, 2 kg of CO2 are saved. On this basis, CO2 savings from PVC recycling in Europe are 16.2 million tonnes since 2000. Recycled PVC’s primary energy demand is up to 90% lower than virgin PVC production. PVC recycling also creates green jobs – the 813,266 tonnes of PVC pipes and other products recycled in Europe in 2022 through VinylPlus contributed to the creation of more than 1,600 direct jobs in recycling plants.

Cost-Benefit Analyses highlight economic benefits of recycling

Plastic recycling not only contributes to creation of green European jobs and resource, energy, and carbon savings. Through the methodology of Cost-Benefit Analysis (CBA), it has been demonstrated that recycling versus incineration or landfilling of PVC pipes yields significant cost benefits. Even as Europe grapples with rising energy costs, the economic rationale for PVC pipe recycling remains compelling.

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025

-

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

NewsAug.17,2025

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025