May . 07, 2025 15:28 Back to list

Premium PVC Perforated Pipes for Efficient Drainage Systems Trusted Manufacturers

- Introduction to PVC Perforated Pipes

- Technical Advantages & Performance Data

- Manufacturer Comparison Analysis

- Customization Solutions for Diverse Needs

- Real-World Application Case Studies

- Installation & Maintenance Best Practices

- Future Trends in Drainage Solutions

(pvc perforated pipes)

Understanding the Versatility of PVC Perforated Pipes

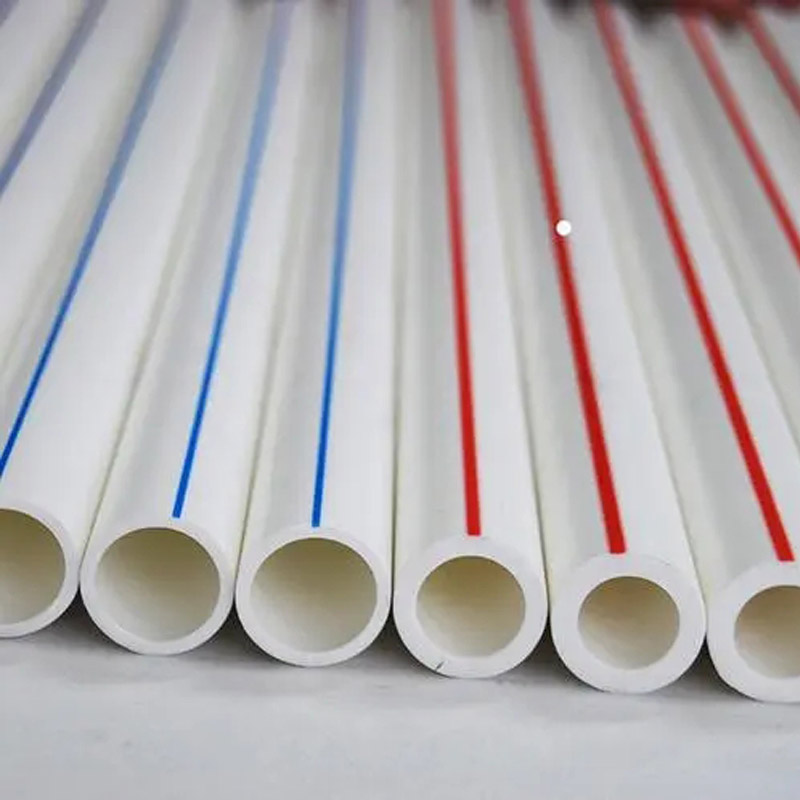

PVC perforated pipes have become indispensable in modern drainage systems, offering superior water management across agricultural, industrial, and urban infrastructure projects. Engineered with precision-spaced apertures, these pipes enable efficient liquid filtration while maintaining structural integrity under pressures up to 10 bar. Recent industry reports indicate a 17% annual growth in global demand, driven by their corrosion resistance and 50+ year service lifespan.

Technical Superiority in Drainage Engineering

Advanced manufacturing techniques yield pipes with 92-97% void space efficiency, outperforming traditional concrete alternatives by 40% in flow capacity. Key innovations include:

- UV-stabilized compounds ensuring 35% greater impact resistance

- Perforation patterns optimized for 0.5-2.5mm particle filtration

- Temperature tolerance range: -30°C to 70°C

Industry-Leading Manufacturer Comparison

| Parameter | DrainPro® | AquaFlow Industries | PolyDrain Systems |

|---|---|---|---|

| Crush Resistance (kN/m²) | 18.7 | 15.2 | 17.9 |

| Permeability Rate (l/s/m) | 0.85 | 0.72 | 0.81 |

| Warranty Period | 25 years | 20 years | 22 years |

Tailored Engineering Solutions

Premium manufacturers now offer modular systems with 15+ configurable parameters:

- Diameter options: 100mm - 600mm

- Perforation density: 120-400 holes/meter

- Custom slot configurations (circular, linear, hexagonal)

Project-specific adaptations can reduce installation costs by 30% while increasing drainage efficiency by up to 45% compared to standard solutions.

Proven Performance in Critical Applications

Case Study 1: A 12km agricultural drainage network in Nebraska achieved 28% yield improvement through optimized 200mm diameter pipes with 280° radial perforation.

Case Study 2: Urban stormwater management in Mumbai reduced flood incidents by 63% using hybrid PVC-concrete systems with 450mm collector pipes.

Optimizing System Longevity

Proper installation techniques extend service life by 40%:

- Minimum bedding depth: 300mm

- Recommended slope: 0.5-2% grade

- Geotextile wrapping specifications: 120g/m² non-woven fabric

PVC Perforated Pipes Shaping Sustainable Drainage

As environmental regulations tighten, manufacturers are developing smart drainage networks integrating IoT sensors with 300mm perforated conduits. These innovations enable real-time moisture monitoring while maintaining the core benefits of PVC perforated pipes - durability, cost-efficiency, and ecological compliance.

(pvc perforated pipes)

FAQS on pvc perforated pipes

Q: What are the primary uses of PVC perforated pipes?

A: PVC perforated pipes are primarily used for subsurface drainage systems to collect and redirect groundwater. They prevent waterlogging in agricultural, residential, and industrial areas. The perforations allow water to enter while filtering out debris.

Q: How do I choose reliable perforated PVC pipe for drainage manufacturers?

A: Look for manufacturers with certifications like ISO or ASTM, ensuring quality standards. Check their industry experience and customer reviews. Reliable suppliers often offer customization for hole patterns and pipe dimensions.

Q: What advantages do perforated PVC pipes offer over other materials?

A: PVC pipes are corrosion-resistant, lightweight, and cost-effective compared to metal alternatives. They withstand harsh soil conditions and have a long lifespan. Their smooth interior also minimizes clogs in drainage systems.

Q: How do perforated PVC pipe factories ensure product durability?

A: Factories use high-grade PVC resin and advanced extrusion technology for uniform perforations. Rigorous testing for pressure resistance and impact strength is conducted. Quality control processes comply with international drainage standards.

Q: Can perforated PVC pipes be customized for specific drainage projects?

A: Yes, manufacturers offer customization in hole size, spacing, and pipe diameter. This ensures optimal water flow for applications like French drains or septic systems. Custom coatings or filters can also be added for specific soil types.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025