Jun . 28, 2024 16:30 Back to list

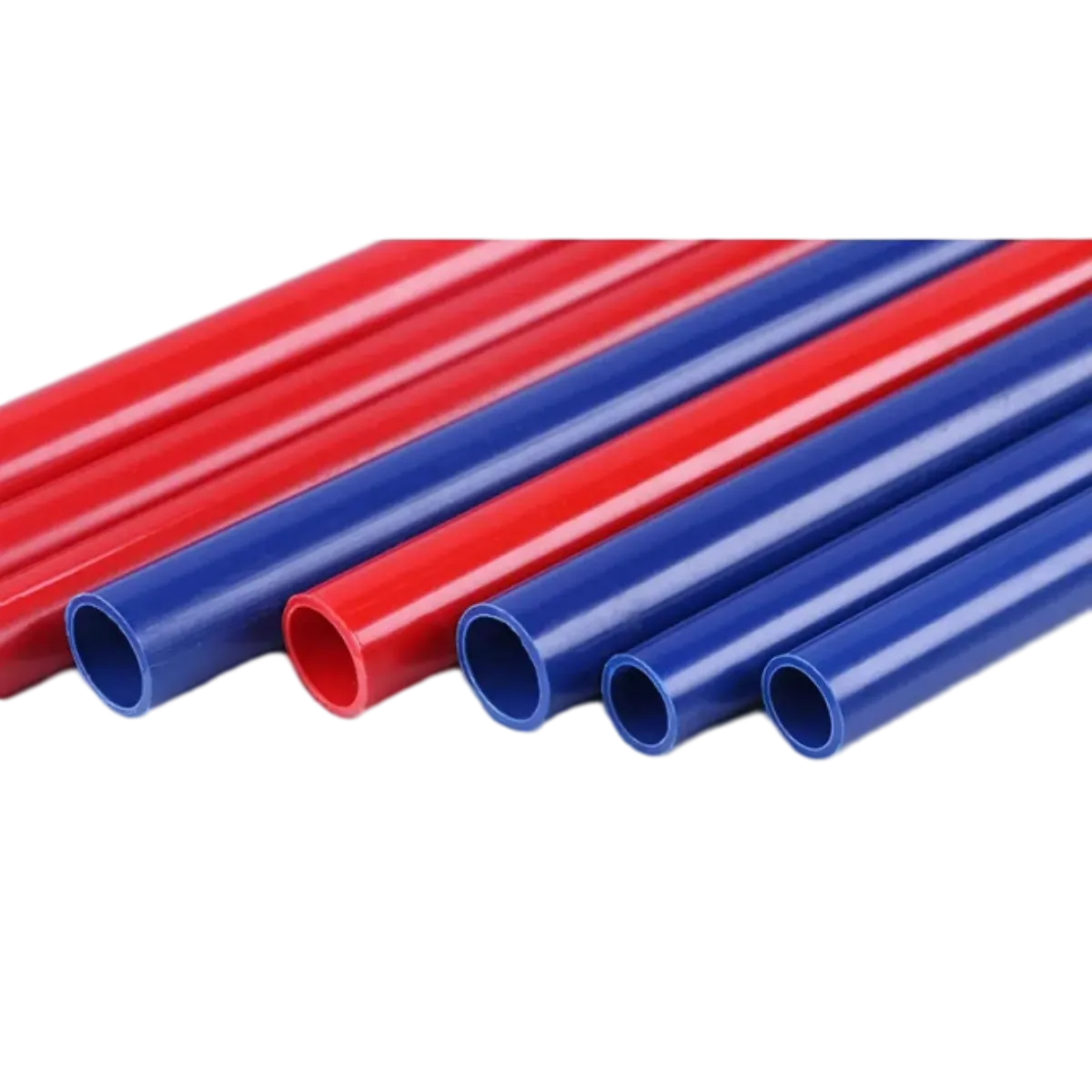

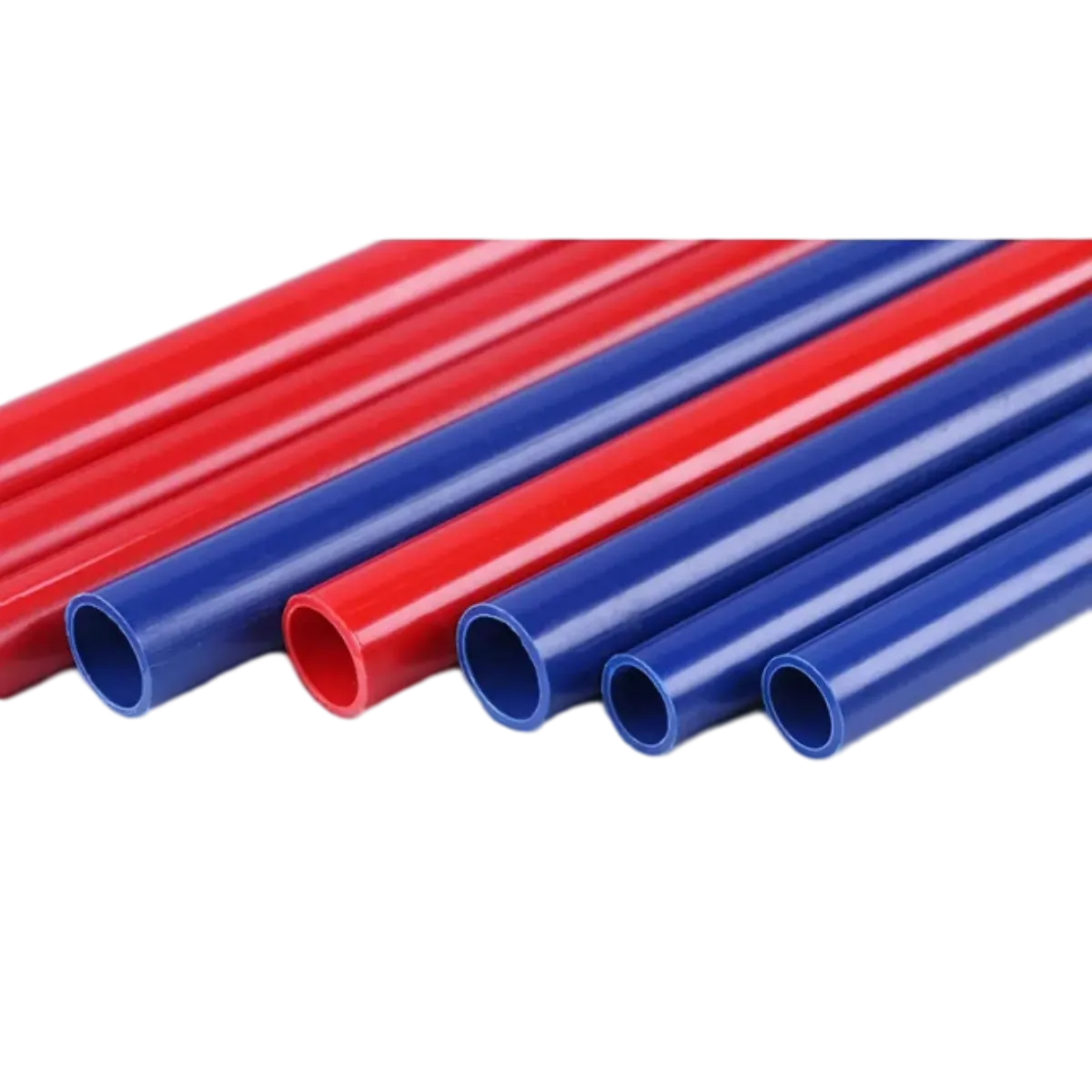

PPR Water Pipe Manufacturing Facilities An Overview of Key Factories

Technological advancements within these factories have led to the production of more sophisticated pipe systems that cater to the needs of diverse applications, from residential to commercial settings Technological advancements within these factories have led to the production of more sophisticated pipe systems that cater to the needs of diverse applications, from residential to commercial settings

Technological advancements within these factories have led to the production of more sophisticated pipe systems that cater to the needs of diverse applications, from residential to commercial settings Technological advancements within these factories have led to the production of more sophisticated pipe systems that cater to the needs of diverse applications, from residential to commercial settings water pipe ppr factories. Furthermore, the focus on quality assurance has elevated standards, ensuring that each pipe meets stringent performance criteria.

However, the proliferation of PPR pipe factories has also presented challenges, including increased competition and concerns over raw material sourcing. As the demand for sustainable building practices grows, manufacturers are under pressure to source recycled or bio-based materials. In response, many factories have started implementing green initiatives, using environmentally friendly processes and reducing waste.

The evolution of PPR water pipe factories reflects broader trends in industrialization and eco-consciousness. Their products not only enhance the reliability of water supply systems but also contribute to the architectural beauty of modern buildings. As these facilities continue to innovate and adapt to global demands, they play a pivotal role in shaping the future of plumbing and water management worldwide.

water pipe ppr factories. Furthermore, the focus on quality assurance has elevated standards, ensuring that each pipe meets stringent performance criteria.

However, the proliferation of PPR pipe factories has also presented challenges, including increased competition and concerns over raw material sourcing. As the demand for sustainable building practices grows, manufacturers are under pressure to source recycled or bio-based materials. In response, many factories have started implementing green initiatives, using environmentally friendly processes and reducing waste.

The evolution of PPR water pipe factories reflects broader trends in industrialization and eco-consciousness. Their products not only enhance the reliability of water supply systems but also contribute to the architectural beauty of modern buildings. As these facilities continue to innovate and adapt to global demands, they play a pivotal role in shaping the future of plumbing and water management worldwide. -

UPVC Column Pipes for Submersible Pumps: Durable & Corrosion-Free

NewsAug.27,2025

-

Premium DN50 HDPE Pipes in Coils: Flexible, Long-lasting Supply

NewsAug.26,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Solutions

NewsAug.25,2025

-

Hot/Cold DN25 PPR Water Pipes for Kitchen | Durable & Food-Safe

NewsAug.24,2025

-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

NewsAug.21,2025