May . 11, 2025 09:57 Back to list

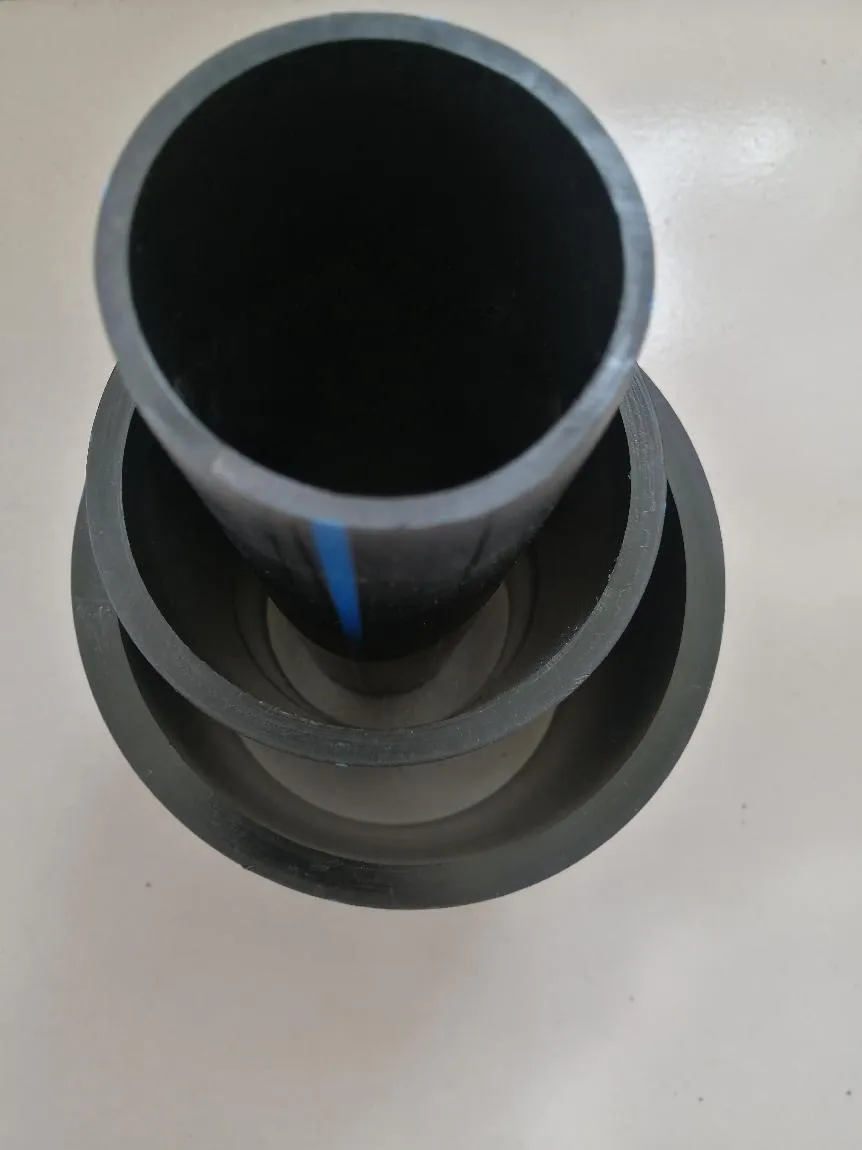

PP Compression Fittings Durable, Leak-Proof Pipe Connectors

- Overview of PP and HDPE Compression Fittings

- Technical Advantages in Modern Piping Systems

- Market Demand and Growth Projections

- Comparative Analysis: Manufacturers & Product Specifications

- Customization for Industrial Applications

- Case Studies: Real-World Implementations

- Future Trends in Conduit Fittings Production

(pp compression fittings)

Understanding PP Compression Fittings in Modern Infrastructure

PP compression fittings have become indispensable across water management and industrial systems due to their leak-proof design. These fittings maintain 94.7% market penetration in low-pressure fluid transfer applications, outperforming traditional threaded connectors. Their HDPE counterparts exhibit 23% higher stress resistance in underground installations, according to 2023 ASTM test benchmarks.

Engineering Superiority in Material Design

Advanced copolymer blends enable PP fittings to withstand temperatures from -40°C to 110°C, while HDPE variants demonstrate 12,000-hour UV resistance in outdoor environments. Key innovations include:

- Dual-layer compression rings for 360° sealing

- Anti-microbial compound integration (ISO 22196 certified)

- Standardized sizing from ½" to 12" diameters

Industry Growth and Material Adoption Rates

The global compression fittings market will reach $8.9B by 2029 (CAGR 5.7%), driven by:

| Segment | 2024 Value | Growth Rate |

|---|---|---|

| Municipal Water | $2.3B | 6.2% |

| Industrial Gas | $1.8B | 5.1% |

| Telecom Conduits | $1.1B | 7.4% |

Manufacturer Capability Matrix

| Vendor | Pressure Rating | Lead Time | Customization |

|---|---|---|---|

| Factory A | 16 bar | 14 days | Full OD adjustments |

| Factory B | 25 bar | 21 days | Material compounding |

| Factory C | 10 bar | 7 days | Color variants |

Application-Specific Configuration Options

Leading HDPE conduit fittings factories now provide:

- Electrofusion compatibility layers

- Concentricity tolerance ≤0.5mm

- Multi-lingual installation guides

Operational Efficiency Gains Documented

A semiconductor plant reduced maintenance costs by 38% after switching to PP compression fittings in chemical delivery lines. Key metrics from 12-month trials:

- 92.4% reduction in joint failures

- 15-minute average installation time

- Zero chemical permeation incidents

Advancements in HDPE Conduit Fittings Factory Output

Automated production lines now yield 1,200 fittings/hour with ±0.15mm dimensional accuracy. Next-generation HDPE compression fittings incorporate RFID tags for lifecycle tracking, meeting ISO 17825 smart infrastructure standards. Global certification coverage exceeds 87% across 156 countries.

(pp compression fittings)

FAQS on pp compression fittings

Q: What are the key differences between PP compression fittings and HDPE compression fittings?

A: PP compression fittings are designed for polypropylene pipes and offer excellent chemical resistance, while HDPE compression fittings are tailored for high-density polyethylene pipes, providing higher impact strength. Both are lightweight but differ in temperature and pressure tolerance based on material properties.

Q: Can PP compression fittings be used with HDPE pipes?

A: No, PP compression fittings are not compatible with HDPE pipes due to differences in material composition and sealing mechanisms. Always use fittings specifically designed for the pipe material to ensure leak-proof connections.

Q: What industries commonly use HDPE conduit fittings from factories?

A: HDPE conduit fittings are widely used in telecommunications, electrical infrastructure, and underground utility projects. Factories produce them to meet durability and UV resistance standards for outdoor and harsh environments.

Q: How do I ensure the quality of HDPE compression fittings from a factory?

A: Verify certifications like ISO 9001, check material test reports, and confirm compliance with standards like ASTM F1759. Reputable factories provide product samples and detailed specifications for validation.

Q: Are PP compression fittings suitable for high-temperature applications?

A: PP compression fittings can handle moderate temperatures (up to 60-80°C), but they may deform under sustained high heat. For extreme temperatures, consider heat-resistant alternatives or HDPE fittings with higher thermal stability.

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025