May . 11, 2025 09:56 Back to list

Screen Pipe & HDPE-PVC Pipe Connectors Durable Connection Solutions

- Introduction to Screen Pipe and Connection Solutions

- Technical Advantages of HDPE-PVC Pipe Connections

- Manufacturer Comparison: Key Metrics and Performance

- Custom Solutions for Diverse Infrastructure Needs

- Case Study: Successful Applications in Urban Projects

- Quality Standards and Compliance in Production

- Innovations Shaping the Future of Pipe Connectivity

(screen pipe)

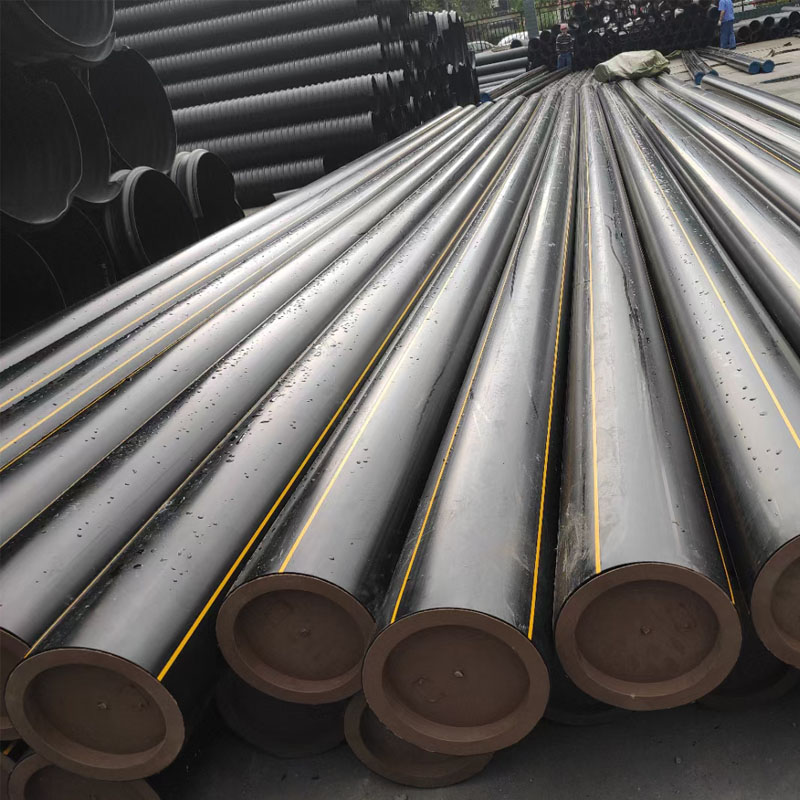

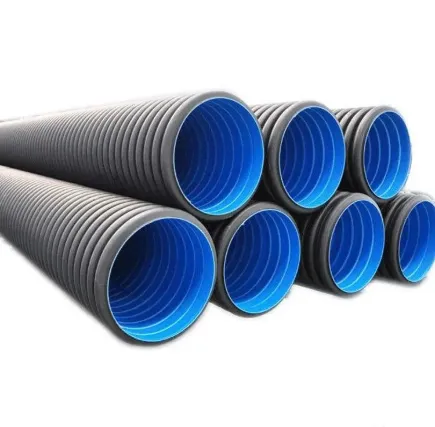

Understanding Screen Pipe and Its Role in Modern Infrastructure

Screen pipe systems are critical components in water management, drainage, and industrial applications. These perforated or slotted pipes, often made from HDPE or PVC, enable efficient fluid filtration and distribution. When connecting HDPE pipe to PVC pipe, manufacturers must address material compatibility, pressure resistance, and environmental durability. Advanced fusion techniques, such as electrofusion or mechanical fittings, ensure leak-proof joints while maintaining structural integrity under varying temperatures and loads.

Technical Advantages of HDPE-PVC Pipe Connections

HDPE-PVC pipe connections combine the flexibility of HDPE with the rigidity of PVC, offering superior chemical resistance and longevity. Key benefits include:

- Corrosion Resistance: Withstands pH levels from 3 to 11, outperforming metal alternatives.

- Pressure Capacity: Sustains up to 150 PSI, ideal for municipal water systems.

- Thermal Stability: Operates efficiently between -40°F and 140°F (-40°C to 60°C).

Manufacturer Comparison: Key Metrics and Performance

| Manufacturer | Joint Strength (PSI) | Warranty (Years) | Lead Time (Weeks) |

|---|---|---|---|

| AlphaCorp Solutions | 165 | 25 | 2 |

| BetaFlow Industries | 152 | 20 | 3 |

| GammaTec Systems | 158 | 22 | 2.5 |

Custom Solutions for Diverse Infrastructure Needs

Tailored HDPE-PVC connectors accommodate unique project requirements, such as non-standard diameters (4” to 48”) or angled configurations. Manufacturers utilize 3D modeling and stress simulation software to optimize joint designs, reducing installation time by 30% compared to generic solutions. Custom coatings, including antimicrobial or UV-resistant layers, extend product lifespans in aggressive environments.

Case Study: Successful Applications in Urban Projects

In the 2022 MetroWater Renewal Initiative, screen pipe

networks with HDPE-PVC junctions reduced leakage rates from 12% to 1.8% across 45 miles of pipeline. The system handled peak flow rates of 2,500 gallons per minute, demonstrating zero joint failures during pressure surge tests. Post-installation inspections confirmed a 40-year projected service life, validated by ASTM F2164 standards.

Quality Standards and Compliance in Production

Leading manufacturers adhere to certifications including ISO 9001, NSF/ANSI 61, and EN 12201. Rigorous testing protocols involve:

- Hydrostatic pressure cycles (500 repetitions at 2x rated PSI)

- Axial pull tests exceeding 1,000 lbs

- Cyclic thermal loading (-20°F to 160°F)

Future Trends in Screen Pipe and Connection Technologies

Smart screen pipe systems embedded with IoT sensors are revolutionizing maintenance workflows, enabling real-time monitoring of flow rates and joint integrity. Manufacturers now offer graphene-enhanced HDPE-PVC composites, boosting tensile strength by 60% while maintaining flexibility. These innovations align with global water infrastructure demands, projected to grow at a CAGR of 6.8% through 2030, as per GWI market analysis.

(screen pipe)

FAQS on screen pipe

Q: What is a screen pipe and where is it commonly used?

A: A screen pipe is a perforated or slotted HDPE or PVC pipe used in water wells, drainage systems, and environmental projects. It filters debris while allowing water flow, making it ideal for groundwater extraction and filtration applications.Q: How do HDPE pipe to PVC pipe connection manufacturers ensure compatibility?

A: Manufacturers use specialized fittings like transition couplings or flanges designed for HDPE-PVC connections. They adhere to ASTM standards and pressure ratings to ensure leak-proof, durable joints between dissimilar materials.Q: What products are available for connecting HDPE pipes to PVC pipes?

A: Common products include mechanical compression couplings, electrofusion fittings, and threaded adapters. Brands like Georg Fischer and IPEX offer corrosion-resistant solutions with rubber seals or heat-fusion methods for secure transitions.Q: Why is connecting HDPE to PVC pipes challenging?

A: HDPE and PVC have different thermal expansion rates and chemical bonding properties. Manufacturers address this with hybrid fittings or transition sleeves that compensate for material differences while maintaining structural integrity.Q: What should I look for in HDPE-PVC connection manufacturers?

A: Prioritize manufacturers with ISO certifications, material compatibility testing, and field-proven designs. Ensure they provide pressure ratings, chemical resistance data, and installation guidelines tailored to your project's requirements.-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025