Jan . 14, 2025 13:00 Back to list

hdpe sprinkler pipe manufacturers

Market Insights and Innovations The competitive landscape of China's HDPE pipe industry is characterized by continuous innovations. The adoption of advanced manufacturing technologies such as extrusion methods and improved resin compositions has resulted in HDPE pipes with enhanced physical properties and extended lifecycle. Chinese manufacturers are also pioneering environmentally sustainable practices in production, a vital consideration for eco-conscious businesses worldwide. As the demand for eco-friendly infrastructure materials grows, so does the adaptability of HDPE pipes, making them an integral component of green building projects. Purchasing Strategies and Supplier Networks For procurement professionals and project managers, choosing the right HDPE pipe size requires strategic supplier engagement. China's expansive network of suppliers offers a variety of customization options. Engaging with suppliers who provide detailed consultation can facilitate the selection of optimal pipe sizes tailored to specific project requirements. Evaluating historical performance, client testimonials, and after-sales support are integral to choosing a trustworthy supplier. Additionally, leveraging partnerships with local distributors can enhance order customization and reduce delivery lead times, crucial for maintaining project schedules. Conclusion China's HDPE pipe size range is extensive and designed to cater to a myriad of industrial and commercial needs. For businesses and infrastructure planners, understanding these sizes, alongside the innovative approaches adopted by Chinese manufacturers, can significantly influence project success. Trust in quality assurance, coupled with strategic purchasing strategies, positions stakeholders to optimize the benefits derived from HDPE pipes, thereby achieving durable, efficient, and cost-effective infrastructural solutions.

-

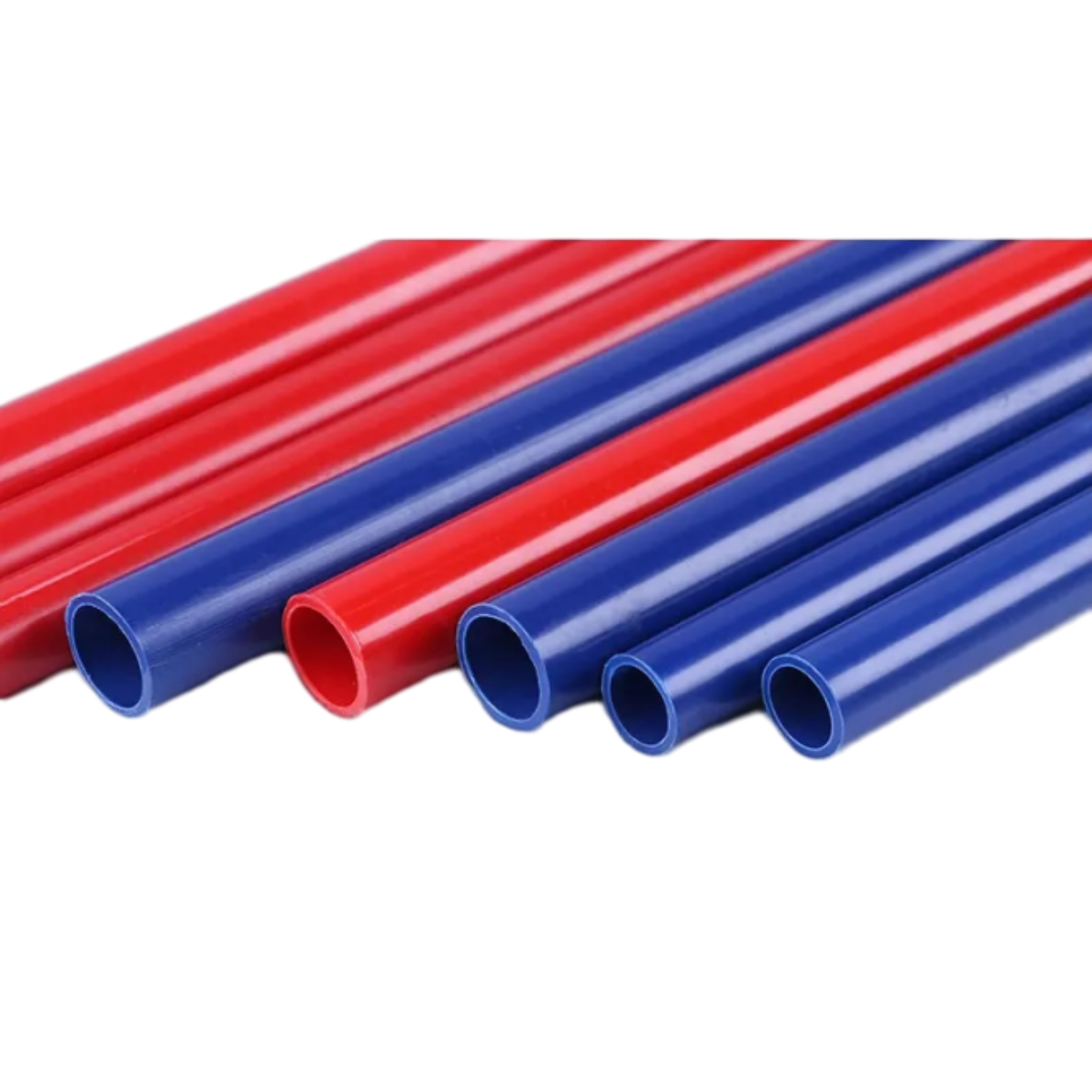

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025

-

High-Quality DN150 HDPE Pipes for Gas Delivery – Durable & Leak-Proof

NewsJul.29,2025

-

140mm PVC Drilling Pipe for Efficient Borehole Drilling Solutions

NewsJul.29,2025

-

High-Quality UPVC Column Pipes for Submersible Pumps – Corrosion Resistant

NewsJul.29,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.28,2025