Dec . 02, 2024 03:29 Back to list

Cost Analysis of HDPE Pipe Products for Various Applications

Understanding HDPE Pipe Costs and Products

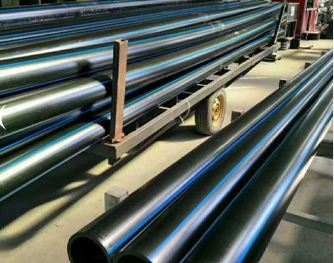

High-Density Polyethylene (HDPE) pipes are a highly versatile and durable option for a variety of applications, including water distribution, sewage, and industrial processes. As infrastructure needs grow, the demand for HDPE pipes continues to rise. Understanding the factors that influence HDPE pipe costs is essential for engineers, contractors, and procurement managers. This article will delve into the various components that determine the cost of HDPE pipes, as well as the advantages they offer.

Factors Influencing HDPE Pipe Costs

1. Material and Production Costs The primary factor affecting the cost of HDPE pipes is the price of polyethylene resin, the raw material used in their manufacturing. The price of resin can fluctuate due to changes in oil prices, manufacturing capacity, and market demand. Additionally, the production process—including extrusion and molding—can impact the overall cost. Manufacturers employ different technologies and methods, which may lead to variations in pricing.

2. Pipe Size and Thickness The dimensions of the HDPE pipe directly influence its cost. Larger diameter pipes require more material and are generally priced higher than smaller ones. Furthermore, pipe thickness, which is measured in Schedule or SDR (Standard Dimension Ratio), also affects cost. Thicker pipes are more expensive but offer greater strength and longevity, suitable for high-pressure applications.

3. Length and Quantity HDPE pipes are typically sold in standard lengths, often 20 or 40 feet. Purchasing in bulk can lead to significant discounts, as manufacturers usually reduce prices when larger quantities are ordered. Additionally, the length of the pipes can influence transport costs, as longer lengths may require special handling.

4. Manufacturing Standards and Certifications Pipes that meet specific industry standards or have additional certifications for safety and performance often come at a higher price. For instance, HDPE pipes certified for potable water use must meet stringent regulations, which may add to the cost due to enhanced testing and quality assurance processes.

5. Market Competition and Regional Variations The competitive landscape can significantly affect pricing. In regions where there are multiple suppliers, prices may be more competitive. On the other hand, in areas where fewer suppliers exist, costs may be higher due to limited options. Shipping costs can also vary by location, impacting the overall price for buyers in different regions.

hdpe pipe cost products

Advantages of Using HDPE Pipes

Despite the various factors affecting costs, there are many reasons why HDPE pipes are a preferred choice in many applications

- Durability and Longevity HDPE pipes are resistant to corrosion, chemicals, and abrasion, which makes them suitable for a wide range of environments. Their longevity often outweighs initial costs by reducing the frequency of replacements.

- Flexibility and Lightweight Their flexibility allows for easier installation, especially in challenging terrains. Additionally, being lightweight reduces transportation and installation costs.

- Low Friction Coefficient HDPE pipes have a smooth interior surface, which leads to lower friction and reduced energy consumption for pumping fluids.

- Environmentally Friendly HDPE is recyclable, and with proper management, it presents a less environmentally damaging option compared to traditional materials.

Conclusion

The cost of HDPE pipes is influenced by a multitude of factors including material prices, pipe dimensions, manufacturing standards, and market conditions. While initial costs may vary, the benefits—such as durability, flexibility, and environmental sustainability—make HDPE pipes a valuable investment in infrastructure projects. When selecting HDPE pipe products, it's essential to consider both immediate and long-term needs to ensure the best value for your project. Understanding these dynamics will help stakeholders make informed decisions in sourcing HDPE piping solutions.

-

HDPE & PPR Pipe Elbows Durable, Corrosion-Resistant Solutions

NewsJun.01,2025

-

HDPE Tee Fittings 48-Inch HDPE Pipe Solutions & Cost Optimization

NewsJun.01,2025

-

Premium PVC Perforated Pipes for Efficient Drainage Trusted Factories

NewsMay.31,2025

-

Premium Perforated PVC Pipes for Drainage Solutions Trusted Factories & Manufacturers

NewsMay.31,2025

-

HDPE Electrofusion Fittings Durable, Leak-Proof Conduit Solutions

NewsMay.31,2025

-

HDPE Compression Fittings Leak-Proof, Corrosion-Resistant Solutions

NewsMay.31,2025