Sep . 08, 2024 12:07 Back to list

HDPE Pipe Price List - Quality HDPE Pipes at Competitive Prices

Understanding HDPE Pipe Pricing A Comprehensive Guide

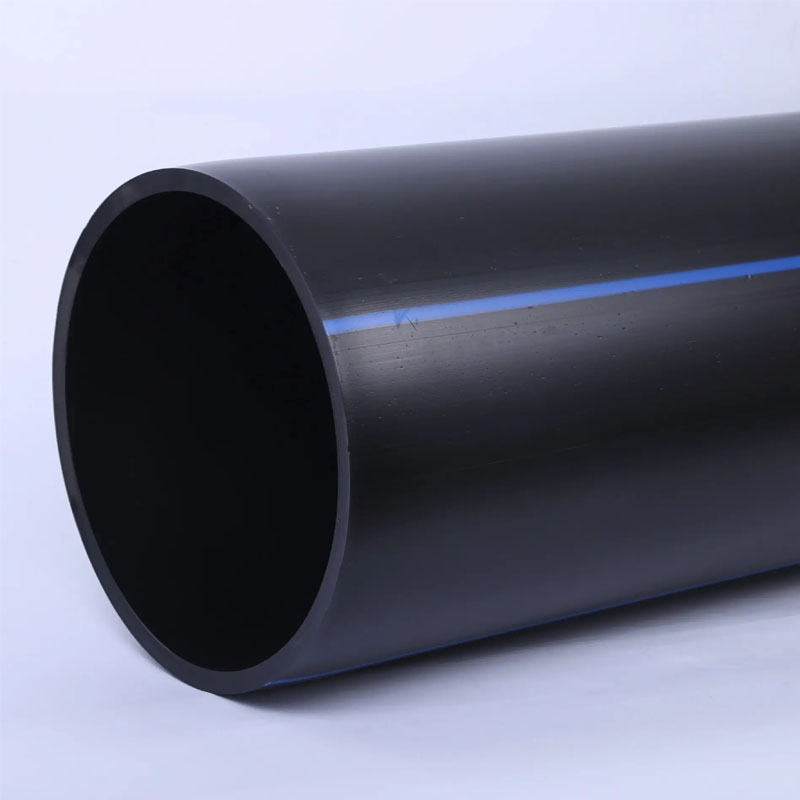

High-Density Polyethylene (HDPE) pipes are widely recognized for their durability, flexibility, and resistance to many chemicals and environmental factors. As a result, they are extensively used in various applications, including water supply, sewage, drainage, and industrial processes. If you're in the market for HDPE pipes, understanding the pricing can help you make informed decisions for your projects.

Factors Affecting HDPE Pipe Prices

Several key factors impact the pricing of HDPE pipes

1. Material Quality The quality of the polyethylene resin used in manufacturing HDPE pipes significantly influences the price. Higher-grade materials typically lead to more expensive pipes but offer better performance and longevity.

2. Pipe Diameter and Wall Thickness The size of the pipe is another crucial determinant of cost. Larger diameter pipes or those with increased wall thickness require more materials and thus come at a higher price.

3. Manufacturing Process The methods used to produce HDPE pipes—such as extrusion and molding—can affect production costs. Advanced manufacturing processes may lead to higher prices but often result in improved product quality.

4. Length of Pipe Standard lengths, typically 20 or 40 feet, can influence the pricing. Custom lengths may incur additional charges due to the need for specific cutting and handling processes.

5. Market Conditions Just like any other commodity, HDPE prices are subject to fluctuations based on supply and demand dynamics, raw material costs, and global market trends. Seasonal demand can also impact pricing, especially in regions with specific weather-dependent applications.

hdpe pipe price list pdf factory

6. Brand Reputation Well-established manufacturers may charge more due to their reputation for quality and reliability. Investing in reputable brands can provide long-term benefits, even if the initial cost is higher.

7. Accessories and Fittings The need for additional fittings, connectors, or specialty products can drive up overall costs. Assessing the complete piping system, including all needed accessories, is essential for budgeting.

Price Range Overview

While specific prices can vary significantly based on the aforementioned factors, a general price range for HDPE pipes might be as follows

- Small Diameter Pipes (1 inch to 6 inches) Prices typically range from $0.50 to $2.00 per linear foot, depending on the quality and specifications. - Medium Diameter Pipes (8 inches to 14 inches) Prices can range from $2.00 to $5.00 per linear foot. - Large Diameter Pipes (16 inches and above) Costs can escalate from $5.00 to $10.00 or more per linear foot for specialized applications.

Conclusion

When sourcing HDPE pipes, it is crucial to consult a price list from reputable manufacturers or suppliers. Typically, a comprehensive pricing document, possibly in PDF format, outlines various pipe specifications and associated costs. This document serves as a crucial tool for contractors, engineers, and project managers to estimate budgets accurately and make informed purchasing decisions.

In summary, while the initial investment in HDPE pipes might seem significant, their long-term benefits—such as durability, low maintenance, and efficiency—often outweigh the upfront costs. By understanding the factors that influence pricing and considering the best quality for your needs, you can ensure that your project is successful and meets all requirements.

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025

-

Flexible 32mm HDPE Pipes in Coil | Durable Water & Gas Lines

NewsAug.12,2025

-

DN50 HDPE Pipes in Coils: Flexible, Durable & Easy Install

NewsAug.11,2025

-

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

NewsAug.10,2025

-

140mm PVC Drilling Pipe: Durable & Efficient Well Casings

NewsAug.09,2025