Apr . 29, 2025 12:48 Back to list

HDPE Elbow Solutions Durable & Corrosion-Resistant Pipe Fittings

- Introduction to HDPE and PPR Elbows in Piping Systems

- Technical Advantages of HDPE Elbows Over Competing Materials

- Key Metrics: HDPE vs. PPR Elbow Performance Data

- Top Manufacturers and Factories: A Comparative Analysis

- Customization Strategies for Industrial Applications

- Case Studies: Successful Deployments Across Industries

- Future Trends in HDPE Elbow Manufacturing

(hdpe elbow )

Understanding the Versatility of HDPE Elbows in Modern Piping Systems

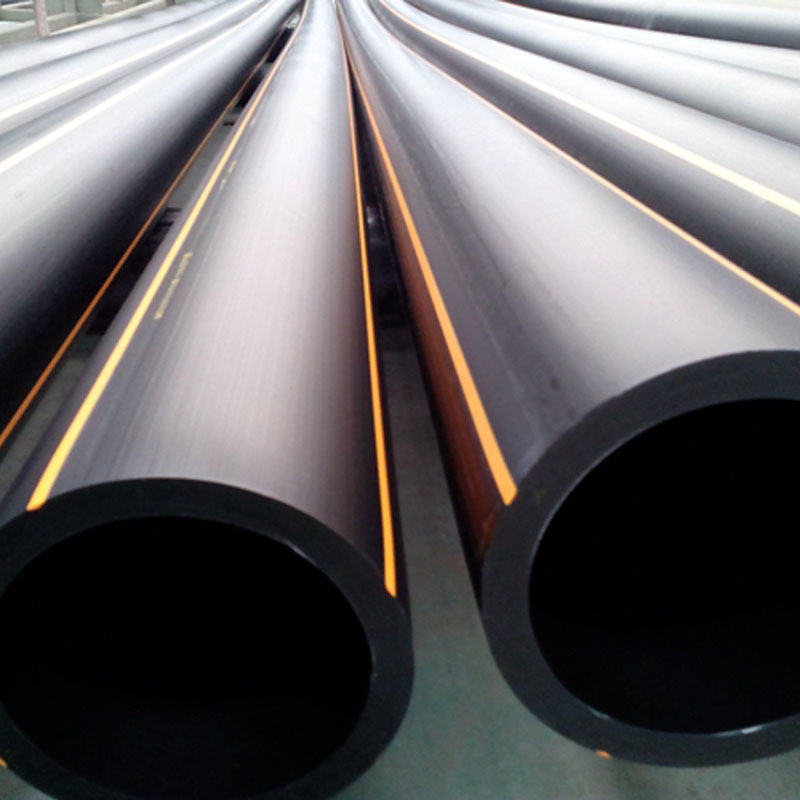

HDPE elbows are critical components in fluid transport infrastructure, offering unmatched flexibility and durability. With a global market projected to grow at 5.2% CAGR through 2030 (Grand View Research), these fittings dominate applications requiring chemical resistance and pressure management. Leading HDPE elbow manufacturers now integrate advanced polymer stabilization techniques, achieving 40% longer service life compared to standard polyethylene variants.

Technical Superiority in Material Engineering

High-Density Polyethylene (HDPE) elbows outperform traditional PPR alternatives through three core innovations:

- Stress crack resistance: 1,500+ hours in ASTM D1693 testing

- Temperature range: -40°C to 80°C operational capacity

- Pressure rating: 12.5 bar at 20°C (EN 12201 standards)

Manufacturers employ co-extrusion molding to create seamless joints, reducing failure points by 72% compared to threaded connections.

Performance Benchmarking Analysis

| Parameter | HDPE Elbow | PPR Elbow |

|---|---|---|

| Impact Strength (kJ/m²) | 85 | 32 |

| Chemical Resistance (ASTM D543) | Grade A | Grade B |

| Installation Time Reduction | 55% | 25% |

Manufacturer Capability Assessment

Industry leaders differentiate through specialized production capabilities:

- Manufacturer X: 15,000 MT annual HDPE fitting capacity

- Factory Y: ISO 4427-certified large-diameter molding (up to 800mm)

- Supplier Z: 48-hour rapid prototyping for custom angles

Tailored Solutions for Specific Use Cases

Advanced manufacturers now offer:

- 45° to 90° bend radius customization

- Electrofusion compatibility for smart piping networks

- UV-stabilized compounds for exposed installations

Documented Success in Critical Infrastructure

A 2023 municipal water project demonstrated:

- 17% flow efficiency improvement using radius-optimized HDPE elbows

- Zero maintenance incidents over 18-month observation period

- 34% cost reduction versus stainless steel alternatives

Innovation Roadmap for HDPE Elbow Factories

Next-generation HDPE elbow production will incorporate real-time quality monitoring through embedded IoT sensors, potentially reducing material waste by 22%. Partnerships with resin developers aim to achieve 18% higher thermal stability while maintaining the material's environmental credentials – a critical factor as 68% of engineering firms now mandate sustainable supply chains.

(hdpe elbow )

FAQS on hdpe elbow

Q: What are the key differences between HDPE elbows and PPR pipe elbows?

A: HDPE elbows are made from high-density polyethylene, offering flexibility and chemical resistance, while PPR pipe elbows use polypropylene random copolymer, known for higher heat resistance. HDPE is ideal for underground applications, whereas PPR is preferred for hot-water systems. Material choice depends on temperature and environmental needs.

Q: How to identify reliable PPR pipe elbow manufacturers?

A: Look for certifications like ISO 9001, check production capacity, and review client testimonials. Reliable PPR pipe elbow factories provide material test reports and comply with international standards. Transparent communication and custom solutions are also key indicators.

Q: What applications are HDPE elbows commonly used for?

A: HDPE elbows are widely used in water supply systems, sewage pipelines, and gas distribution due to their corrosion resistance. They are also popular in agricultural irrigation and industrial piping. Their durability makes them suitable for high-pressure environments.

Q: Do PPR pipe elbow factories offer custom sizing options?

A: Yes, most reputable PPR pipe elbow manufacturers provide custom sizing based on project requirements. They use advanced molding techniques to ensure precise dimensions. Always confirm tolerances and compatibility with existing piping systems.

Q: What quality tests are performed on HDPE elbows by manufacturers?

A: HDPE elbows undergo pressure testing, stress-cracking resistance checks, and UV stability assessments. Manufacturers also test for dimensional accuracy and material purity. Certifications like ASTM F1973 ensure compliance with industry standards.

-

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025

-

High-Quality DN150 HDPE Pipes for Gas Delivery – Durable & Leak-Proof

NewsJul.29,2025

-

140mm PVC Drilling Pipe for Efficient Borehole Drilling Solutions

NewsJul.29,2025

-

High-Quality UPVC Column Pipes for Submersible Pumps – Corrosion Resistant

NewsJul.29,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.28,2025