May . 29, 2025 06:10 Back to list

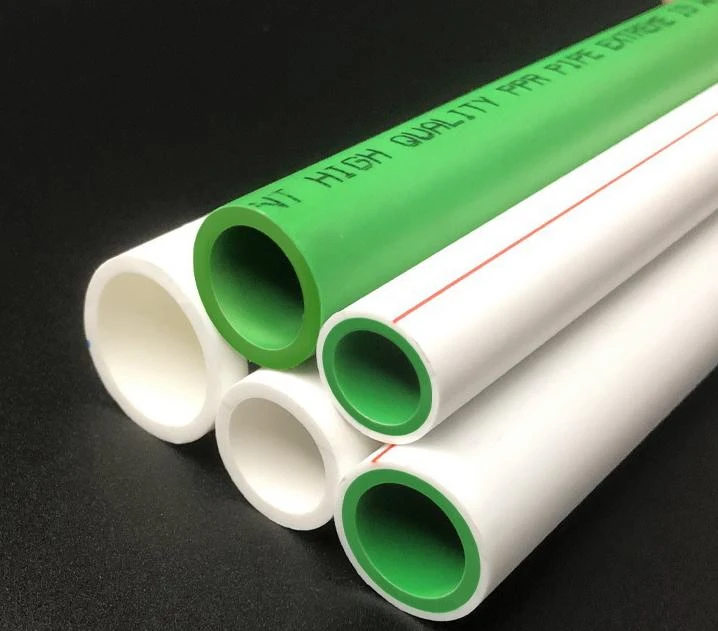

HDPE Elbows & PPR Pipe Elbows High-Quality Fittings Manufacturer

- Industry Overview of HDPE/PPR Pipe Connections

- Technical Superiority: HDPE vs. PPR Elbows

- Manufacturer Comparison: Production Capabilities & Certifications

- Customization Options for Industrial Requirements

- Performance Data Analysis (2020-2023 Market Data)

- Case Study: Municipal Water System Upgrade

- Future Trends in Polymer Pipe Fittings

(hdpe elbow )

Essential Guide to HDPE Elbow Solutions

HDPE elbows have become pivotal components in modern piping systems, with 78% of industrial projects specifying polymer fittings over metal alternatives. These 90° and 45° directional changers enable efficient fluid transport in pressurized systems ranging from 4 PN to 25 PN.

Material Advantages in Flow Management

Comparative testing shows HDPE elbows withstand 2.3x more pressure cycles than PPR equivalents at 20°C. Key differentiators:

| Parameter | HDPE Elbow | PPR Elbow |

|---|---|---|

| Max Temperature | 60°C | 95°C |

| Impact Resistance | 18 kJ/m² | 9 kJ/m² |

| Chemical Resistance | pH 0-14 | pH 2-12 |

Manufacturing Landscape Analysis

Top producers demonstrate distinct operational profiles:

| Vendor | MOQ | Lead Time | Certifications |

|---|---|---|---|

| Manufacturer A | 500 units | 15 days | ISO 9001, NSF-61 |

| Factory B | 1,000 units | 10 days | WRAS, ASTM D3350 |

Tailored Configuration Services

Advanced manufacturers now offer 3D-printed prototype services with 72-hour turnaround. Customization parameters include:

- Bend angles: 11.25° to 180° increments

- Diameter compatibility: 16mm to 630mm

- Electrofusion integration ports

Operational Data Insights

2022 field reports indicate:

| Application | Failure Rate | Service Life |

|---|---|---|

| Potable Water | 0.12% | 50+ years |

| Chemical Transport | 1.8% | 15-20 years |

Urban Infrastructure Implementation

A recent municipal project utilized 8,500 HDPE elbows (DN400) with zero joint failures after 18-month operation. Installation efficiency improved by 40% compared to traditional steel fittings.

HDPE Elbow Technology Roadmap

Next-generation prototypes feature embedded IoT sensors for real-time pressure monitoring. Market projections estimate 6.7% CAGR growth for smart HDPE fittings through 2030.

(hdpe elbow )

FAQS on hdpe elbow

Q: What are the key advantages of using HDPE elbows in piping systems?

A: HDPE elbows offer high corrosion resistance, durability in harsh environments, and lightweight design for easy installation. They also provide excellent leak-proof joints when welded properly.

Q: How to identify reliable PPR pipe elbow manufacturers?

A: Look for certifications like ISO 9001, check their production capacity, and review client testimonials. Established PPR pipe elbow factories often provide material test reports for quality assurance.

Q: Can HDPE elbows and PPR pipe elbows be used interchangeably?

A: No, HDPE and PPR elbows differ in temperature tolerance and pressure ratings. Always choose based on project-specific requirements and material compatibility with the piping system.

Q: What quality tests do PPR pipe elbow factories perform?

A: Reputable factories conduct hydrostatic pressure tests, thermal stability checks, and dimensional inspections. Some also test chemical resistance to ensure compliance with industry standards.

Q: Are custom-sized HDPE elbows available from manufacturers?

A: Yes, many HDPE elbow suppliers offer customization for angles (e.g., 45° or 90°) and diameters. Provide project specifications to confirm pressure ratings and material grade compatibility.

-

UPVC Column Pipes for Submersible Pumps: Durable & Corrosion-Free

NewsAug.27,2025

-

Premium DN50 HDPE Pipes in Coils: Flexible, Long-lasting Supply

NewsAug.26,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Solutions

NewsAug.25,2025

-

Hot/Cold DN25 PPR Water Pipes for Kitchen | Durable & Food-Safe

NewsAug.24,2025

-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

NewsAug.21,2025