Jul . 07, 2024 06:40 Back to list

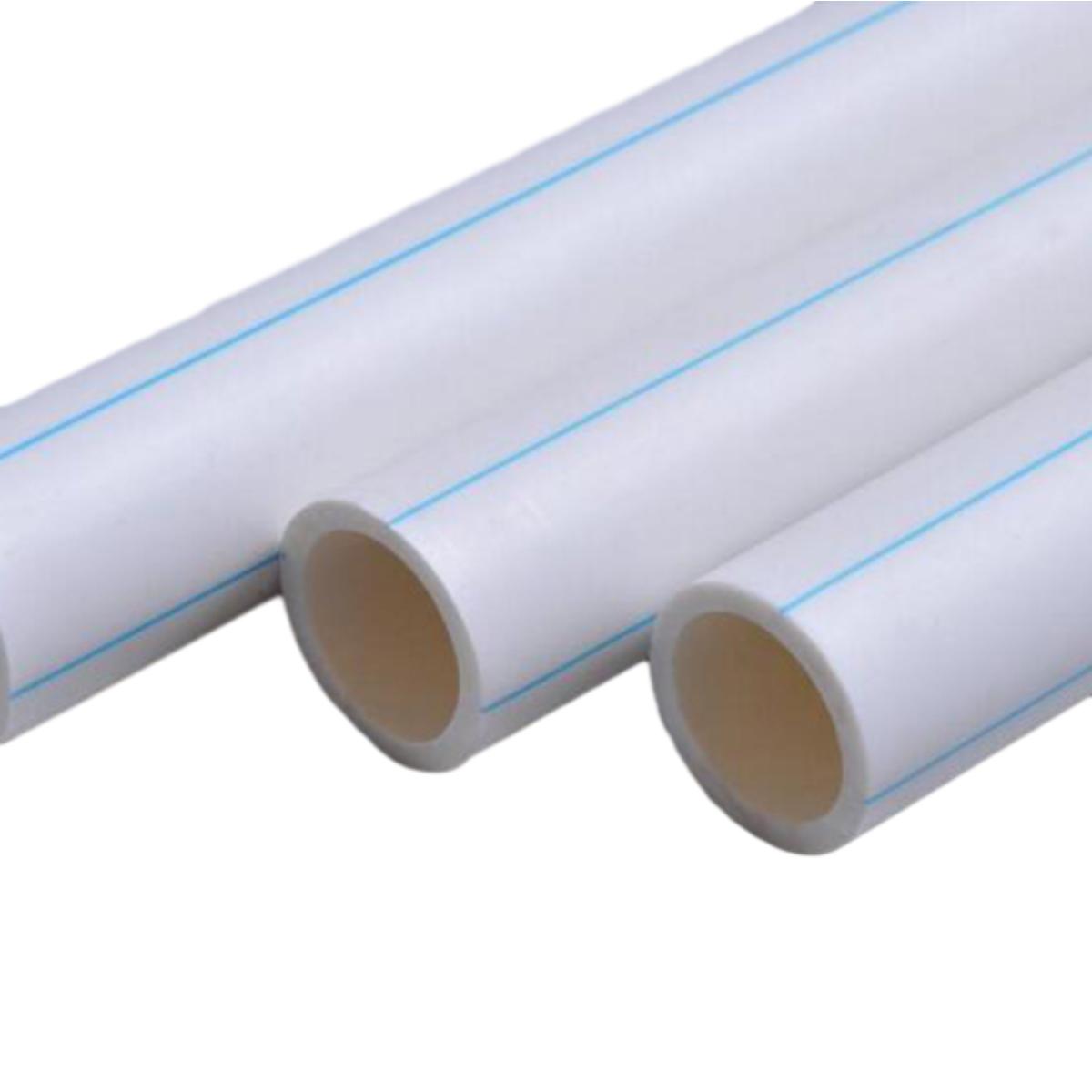

Factory producing under sink water pipes for plumbing systems in residential buildings

After the pipes are molded, they are cooled and inspected for any imperfections

After the pipes are molded, they are cooled and inspected for any imperfections

After the pipes are molded, they are cooled and inspected for any imperfections

After the pipes are molded, they are cooled and inspected for any imperfections water pipes under sink factory. Any faulty pipes are discarded, and only the highest quality pipes are selected for installation. The pipes are then coated with a protective layer to prevent corrosion and ensure a long lifespan.

Once the pipes are manufactured and inspected, they are packaged and shipped to retailers or wholesalers. From there, they are sold to homeowners, contractors, and plumbers who install them in homes and buildings. The installation process is relatively straightforward, but it requires knowledge and skill to ensure that the pipes are properly connected and sealed to prevent leaks.

Overall, water pipes under the sink are an essential component of our plumbing system. Without them, we would not have access to clean and safe drinking water in our homes. The manufacturing process is a highly specialized and intricate one that requires attention to detail and quality control at every step. By using high-quality materials and skilled craftsmanship, manufacturers can create durable and reliable water pipes that will last for years to come.

water pipes under sink factory. Any faulty pipes are discarded, and only the highest quality pipes are selected for installation. The pipes are then coated with a protective layer to prevent corrosion and ensure a long lifespan.

Once the pipes are manufactured and inspected, they are packaged and shipped to retailers or wholesalers. From there, they are sold to homeowners, contractors, and plumbers who install them in homes and buildings. The installation process is relatively straightforward, but it requires knowledge and skill to ensure that the pipes are properly connected and sealed to prevent leaks.

Overall, water pipes under the sink are an essential component of our plumbing system. Without them, we would not have access to clean and safe drinking water in our homes. The manufacturing process is a highly specialized and intricate one that requires attention to detail and quality control at every step. By using high-quality materials and skilled craftsmanship, manufacturers can create durable and reliable water pipes that will last for years to come. -

HDPE & PPR Pipe Elbows Durable, Corrosion-Resistant Solutions

NewsJun.01,2025

-

HDPE Tee Fittings 48-Inch HDPE Pipe Solutions & Cost Optimization

NewsJun.01,2025

-

Premium PVC Perforated Pipes for Efficient Drainage Trusted Factories

NewsMay.31,2025

-

Premium Perforated PVC Pipes for Drainage Solutions Trusted Factories & Manufacturers

NewsMay.31,2025

-

HDPE Electrofusion Fittings Durable, Leak-Proof Conduit Solutions

NewsMay.31,2025

-

HDPE Compression Fittings Leak-Proof, Corrosion-Resistant Solutions

NewsMay.31,2025