Dec . 09, 2024 22:21 Back to list

China HDPE Reducing Coupling for Piping Systems and Water Management Solutions

Understanding China’s HDPE Reducing Coupling Market

In recent years, the demand for high-density polyethylene (HDPE) reducing couplings has seen substantial growth, especially within China’s burgeoning industrial sector. As a critical component in various piping systems, HDPE reducing couplings serve to connect pipes of differing diameters, ensuring a seamless transition and maintaining the integrity of fluid transfers. This article explores the significance of HDPE reducing couplings in industrial applications, the manufacturing landscape in China, and the trends shaping this market.

The Importance of HDPE Reducing Couplings

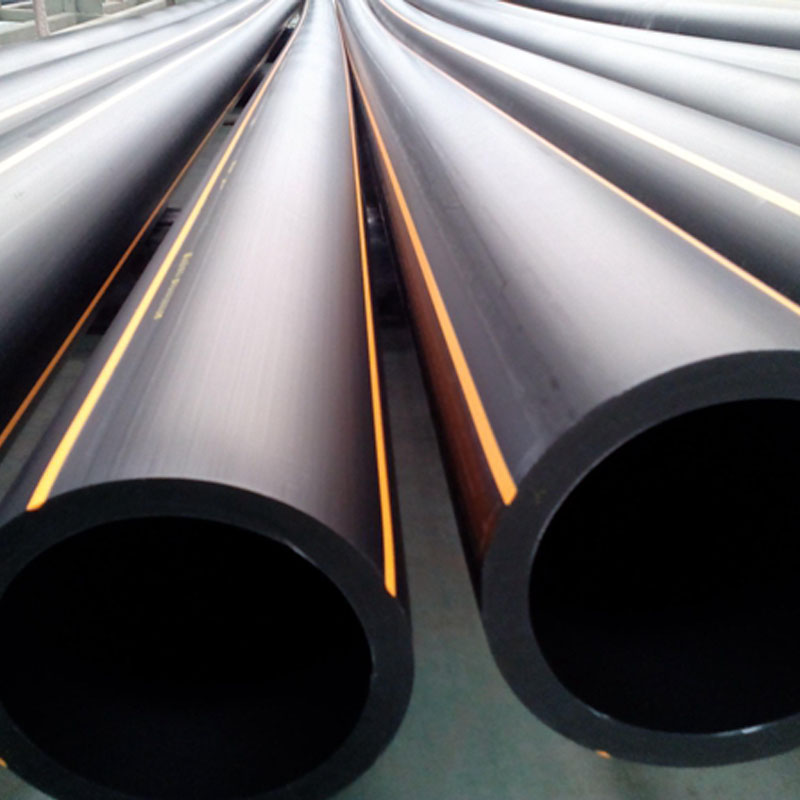

HDPE reducing couplings are indispensable in a multitude of applications ranging from water distribution systems to gas supply networks and even in chemical processing plants. Their primary function is to facilitate a strong, leak-free connection between pipes of varying sizes, which is crucial for maintaining system pressure and functionality. The use of HDPE material offers several advantages, including resistance to corrosion and chemicals, flexibility, and ease of installation. Additionally, HDPE reducing couplings are lightweight compared to metal options, making transport and handling significantly more manageable.

Moreover, the effective integration of these couplings can help in minimizing flow restrictions, enhancing the overall efficiency of the fluid transfer processes. Industries such as agriculture, construction, and municipal waterworks rely heavily on these fittings to ensure reliable and secure pipeline systems.

Manufacturing Landscape in China

China is one of the largest producers of HDPE products globally, and the manufacturing of HDPE reducing couplings is no exception. The country's advanced industrial infrastructure, coupled with the availability of raw materials, has positioned it as a leader in the production of plastic fittings. A variety of manufacturers, ranging from small enterprises to large corporations, contribute to the thriving HDPE coupling market.

china hdpe reducing coupling

Key players in this market focus on utilizing modern techniques and technologies to enhance the quality and durability of their products. Many companies have adopted automated processes that streamline production and reduce costs, allowing them to offer competitive pricing while maintaining high standards of quality. Additionally, strict regulations concerning product quality and safety in China have driven manufacturers to invest in research and development, resulting in innovative designs and improved manufacturing processes.

Trends Influencing the Market

Several trends are influencing the HDPE reducing coupling market in China. Firstly, increasing environmental awareness is prompting industries to adopt more sustainable practices. HDPE, being recyclable, aligns well with these environmental goals, thus driving the demand for products made from this material.

Furthermore, urbanization and infrastructure development in China have led to a surge in the construction of water supply and drainage systems. As cities expand, the need for effective piping solutions grows, leading to greater demand for HDPE reducing couplings. The government's focus on improving water management systems further supports this trend, with initiatives aimed at upgrading existing infrastructure to more efficient and sustainable alternatives.

Additionally, the global push for energy-efficient systems is encouraging industries to shift towards HDPE materials. This move not only improves operational efficiency but also contributes to reduced energy consumption throughout the lifecycle of the products.

Conclusion

The market for HDPE reducing couplings in China is thriving, bolstered by a combination of industrial growth, technological advancements, and an increasing emphasis on sustainability. As the demand for efficient and reliable pipeline solutions continues to rise, China is poised to maintain its status as a key player in this segment. Manufacturers who embrace innovation and sustainability will likely lead the market, positioning themselves favorably in the ever-evolving landscape of industrial materials. With ongoing trends supporting the use of HDPE products, the future looks promising for reducing couplings and their role in modern infrastructure development.

-

HDPE & PPR Pipe Elbows Durable, Corrosion-Resistant Solutions

NewsJun.01,2025

-

HDPE Tee Fittings 48-Inch HDPE Pipe Solutions & Cost Optimization

NewsJun.01,2025

-

Premium PVC Perforated Pipes for Efficient Drainage Trusted Factories

NewsMay.31,2025

-

Premium Perforated PVC Pipes for Drainage Solutions Trusted Factories & Manufacturers

NewsMay.31,2025

-

HDPE Electrofusion Fittings Durable, Leak-Proof Conduit Solutions

NewsMay.31,2025

-

HDPE Compression Fittings Leak-Proof, Corrosion-Resistant Solutions

NewsMay.31,2025