Mar . 13, 2024 10:45 Back to list

PPR PIPES-Connection Method HDPE Pipe

Connection Method HDPE Pipe

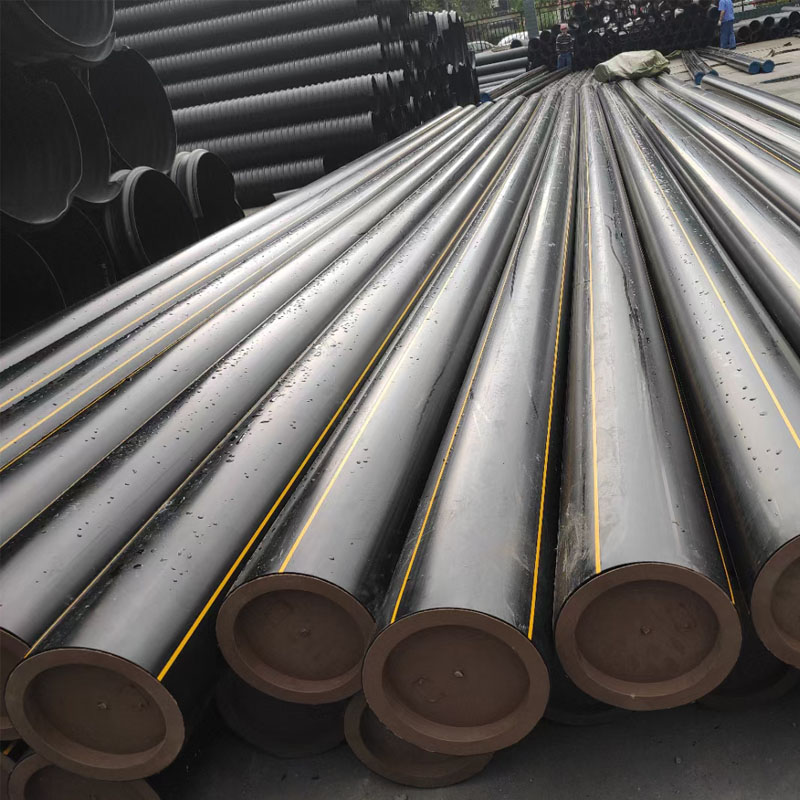

On this occasion we would like to share Information on the method of CONNECTING HDPE pipe. Withtheemits thermoplastic properties, an HDPE pipe connection is done by the heating process. This process makes the connection part have the equivalent strength of the pipe body, so it is not easily damaged and leaked. Before further discussing the process of connecting HDPE pipe, let us understand the nature of the thermoplasticmaterial. This ingredient is very special, so make plastic pipe products have the strength even better than the iron pipe products. Excerpted from the free encyclopedia discussinga Indonesia – wikipedia, thermoplastic is a process of processing plastic materials in a heated way. This process will make the material soft and easy to be formed and connected.

The excess, after the cooling process and the temperature back to normal, the material will harden. Uniquely, the process of heating is done once again will re-create the material soft, so that the process is commonly associated with recycled materials, or materials can be processed into other materials. In terms OF HDPE pipe products, PE-HD (HDPE) material is a branch with two recycling code. This material is known as tough material, Lembab and rigid with a relatively better LEVEL of flexibility than PVC.

Why thermoplastic become an important part in pipe products from HDPE material? Because it is related to the process of connecting HDPE pipe. The thermoplastic properties make the connection part have equal strength to the pipe body. This makes the pipeline uneasily damaged to leak and have a longer usage life. Not only that, the lack of chemical substances such as solvent cement and so make HDPE pipe is recommended for clean water ducts standard food grade. In general, here are some recommended HDPE pipe connection procedures and you learned:

Bonding pipe HDPE Butt Fusion

Bonding pipe HDPE Butt Fusion or commonly known by the process of connecting from end to end (butt) between pipes or accessories fittings. This connection process is done using a heating machine or commonly known as welding machine for HDPE type pipe. Before further, we will discuss how welding machine works for HDPE pipes. This equipment essentially works to connect the pipe end with pipes or accessories with precision heating techniques. We call precision because the pipe part should be connected to one another appropriately. The installation process error will make the connection part not installed perfectly (not precise) and will make the risk of damage and drain leakage very large.

To avoid this, welding machine has a a vise section that is tasked with locking pipes or fittings that will be connected. This process is done so that the pipes or fittings do not move except fore and backward. In addition, to get the result of the perfect connection HDPE pipe, the part to be connected should have a flat shape. This makes the process of heating two tips in one perfect run time. To ensure this, the machine is equipped with a two-way Absorut tool. The function of leveling two ends at a time simultaneously before the heating process.

An important part in welding machine is the heating plate. Like the Ambuting tool, this section has two right and left sections. So the heating process can be done at one time. These three parts are very important function and become the secret to the success of the connection of HDPE pipe, especially butt fusion Models. This type of connection Model is suitable for HDPE pipe type rods. Nevertheless, this can also be done for some pipe (roll) products of a certain diameter.

Bonding pipe HDPE Joint Mechanical

The process of bonding PIPE HDPE Mechanical Joint can be a way PenyaMBOf The easiestand simplein the bandIng two other ways. Because this process can be done without the use of chemicals and machinery (heaters) connectors. This is done entirely with a special compression jointfitting. These accessories consist of several inner locking pipes, rubber seals to prevent connection leaks and mechanical locking that can be tightened with the dratting process. To start, you can insert the end of the pipe to be connected. Lock it with a locking section, and refine it by closing the rubber seal parts to avoid leakage. After that, you can tighten with a mechanical dratt locking, which can be fastened manually (by hand or using the appliance).

The connection process in this way is suitable for the type of pipe roll, and suitable for installation process in difficult areas. The area that makes you impossible to carry HDPE pipe connecting machine or Welding Mahchine. To realize the channel line according to the needs, HDPE pipe fittings Compression Joint available in a wide variety of forms. Such as Elbow, reducer, coupler, tee, stub flange and various other types of accessories. All are designed with the same locking process, and are installed without the use of machines and other chemicals.

Connecting HDPE pipe Electro Fusion

Connection of HDPE pipe This type can be a combination of two methods that we have discussed earlier. Because it uses a special connecting machine and use pipe accessories that support this connection process. Electro Fusion Machine works as a source of electrical energy. The machine has two panels, which can be applied with two khsus panels that are also in the fittings section. This electrical energy is then converted into hot energy. Thermal energy is revamped from electrical energy through electro fusion accessories. The way with a coil of the education in the inside of the accessories. This part will heat up and make the inside of the fittings and the outer pipe melt.

As a result, the inside of the fittings and outer pipes will be perfectly compound. The result of the connection will be properly blocked, so it has a very small risk of leakage. This connection is recommended for HDPE pipes that are applied as gas lines. Each connection has its own criteria, so it has its own weaknesses and advantages. And the bonding process of HDPE pipe can be done in various ways, depending on what kind of pipe you use. The correct pipe product selection and bonding process will make the process run perfectly. So that the connection part will be properly blocked and the pipeline has a longer usage age.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025