Nov . 12, 2024 19:14 Back to list

2 inch borewell column pipe price factory

Understanding the Pricing of 2% Borewell Column Pipes from Factories

When it comes to borewell drilling, the choice of materials, especially the column pipes used, can significantly affect the efficiency and longevity of the water extraction system. Among the various sizes available, the 2% borewell column pipe stands out as a popular option for many applications. Understanding the pricing of these pipes from factories is crucial for anyone involved in setting up borewell systems. This article delves into the factors that influence the price of 2% borewell column pipes and highlights the importance of making informed purchasing decisions.

What Are Borewell Column Pipes?

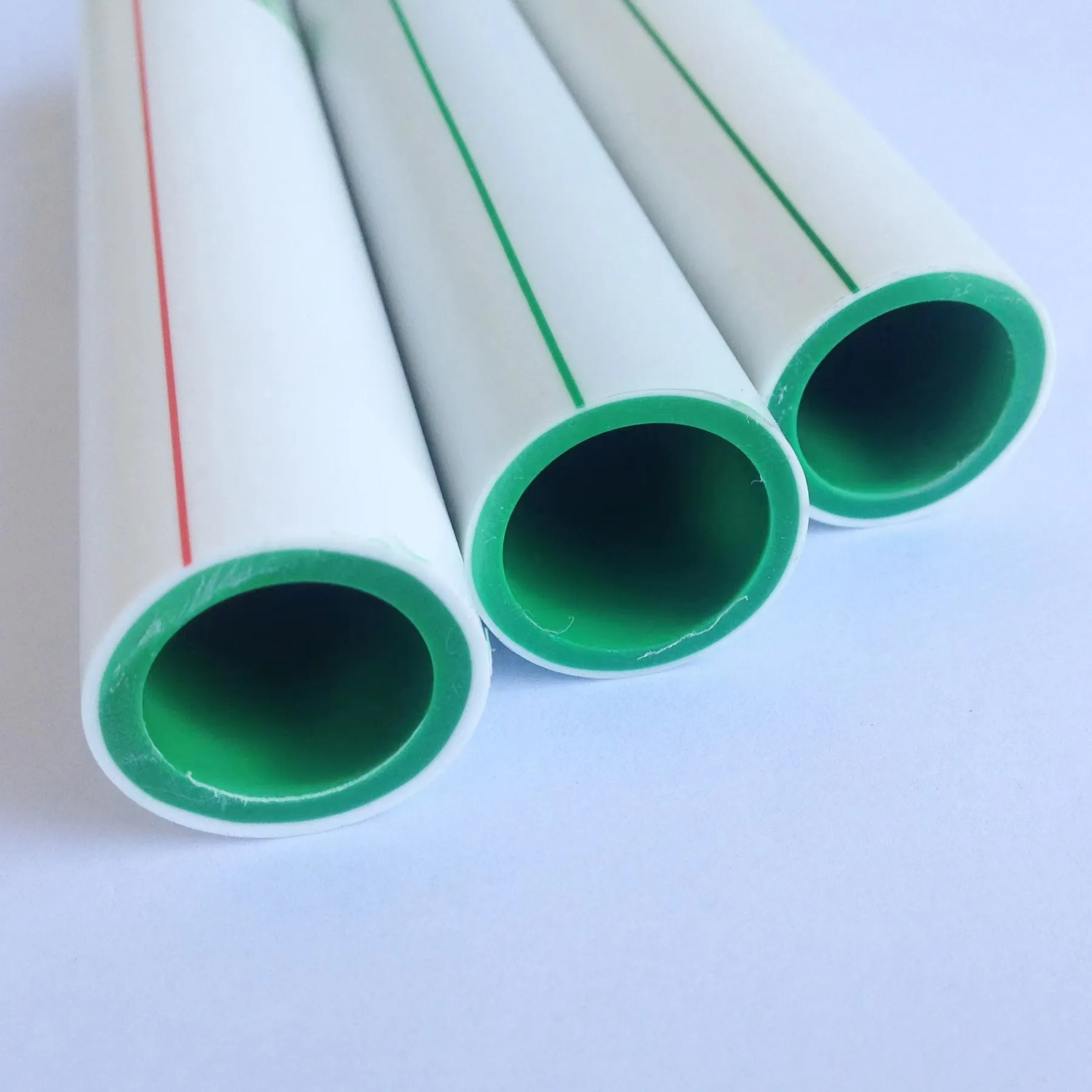

Borewell column pipes are essential components of borewell systems, which are used to extract groundwater from deep underground reserves. These pipes are submerged in the borewell and help in delivering water to the surface. The 2% borewell column pipe, typically made from high-quality materials like PVC or stainless steel, is designed to withstand high pressure and corrosion, ensuring a reliable and safe supply of water.

Factors Influencing the Price

1. Material Quality The primary factor that affects the price of borewell column pipes is the material used in their manufacturing. Pipes made from high-grade stainless steel tend to be more expensive due to their durability and resistance to corrosion. On the other hand, PVC pipes are a more budget-friendly option, though they may not offer the same longevity.

2. Pipe Specifications The diameter, thickness, and length of the 2% borewell column pipe also play a crucial role in determining its price. Custom specifications generally come at a premium. Buyers should carefully assess their needs to avoid overspending on unnecessary features.

2 inch borewell column pipe price factory

3. Manufacturing Process The technology and techniques used in the manufacturing process can impact the price. Pipes produced through advanced methods that ensure better quality and consistency may cost more but can provide better performance over time.

4. Brand Reputation Well-established brands often charge a premium for their products due to their reputation for quality and reliability. Conversely, newer or lesser-known brands may offer lower prices but could compromise on quality, making it essential for buyers to conduct thorough research.

5. Market Demand and Supply The fluctuations in market demand and supply also affect pricing. In times of high demand, prices may increase, while surplus stock might lead to discounts. Seasonal trends can significantly impact the cost, especially in agriculture-dominated regions.

6. Location and Transportation Costs The geographical location of the manufacturer and the transportation logistics can influence the final price. Pipes produced closer to the point of sale may incur lower shipping costs, while distant manufacturers might add extra charges.

Conclusion

When considering the purchase of 2% borewell column pipes from factories, it’s essential to evaluate all factors influencing the price, including material quality, specifications, manufacturing processes, brand reputation, market dynamics, and transportation costs. By doing so, buyers can make well-informed decisions that align with their budget and project requirements.

Investing in the right borewell column pipe is crucial for ensuring a consistent and safe water supply. Therefore, taking the time to explore options, compare prices, and assess the quality of products can lead to significant savings and enhanced performance in the long run.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025