Nov . 12, 2024 19:03 Back to list

hdpe pipe coupling manufacturers

Understanding HDPE Pipe Coupling Manufacturers

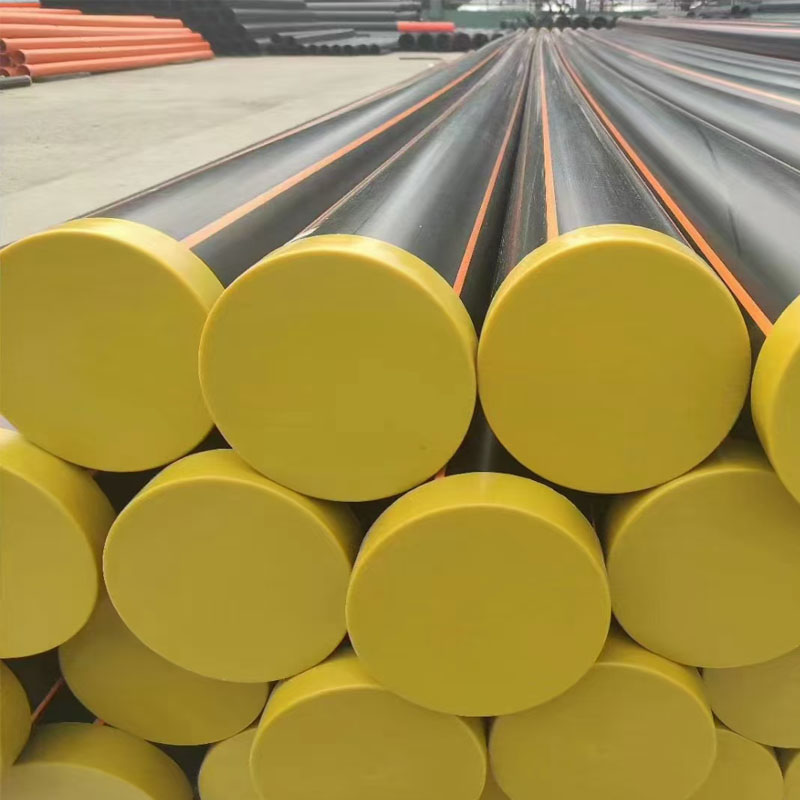

High-Density Polyethylene (HDPE) pipes have gained immense popularity in various industries, including water supply, gas distribution, and sewage systems, due to their durability, flexibility, and resistance to corrosion. Among the essential components in the HDPE piping system are the couplings. They serve as critical connectors that ensure the seamless flow of liquids and gases. This article delves into the role of HDPE pipe coupling manufacturers, highlighting their importance, the manufacturing process, and key considerations when selecting a supplier.

The Role of HDPE Pipe Couplings

HDPE couplings are designed to connect two lengths of HDPE pipes, forming a secure and leak-free joint. They come in various forms, including full couplings, reducing couplings, and transition couplings, which cater to different pipe diameters and applications. The quality of these couplings significantly impacts the overall performance of the piping system. Poorly made couplings can lead to leaks, costly repairs, and even catastrophic failures in some cases.

Manufacturing Process

The manufacturing of HDPE pipe couplings involves several key steps

1. Material Selection HDPE coupling manufacturers use high-quality HDPE resin, characterized by its high tensile strength and flexibility. The resin is typically sourced from reputable suppliers to ensure consistency and reliability in the final product.

2. Molding The selected HDPE resin is heated and then molded into the desired shape. Manufacturers can use different techniques, including injection molding and extrusion, depending on the complexity and size of the couplings being produced.

3. Cooling and Finishing After molding, the couplings are cooled to solidify the plastic. Manufacturers then conduct finishing processes like trimming excess material and surface smoothing to ensure they meet precise specifications.

4. Quality Control Before the couplings leave the factory, they undergo rigorous testing for strength, durability, and dimensional accuracy. This step is crucial to maintain high standards and ensure the product can withstand the stresses of various applications.

hdpe pipe coupling manufacturers

Choosing the Right Manufacturer

When selecting HDPE pipe coupling manufacturers, several factors should be considered

1. Experience and Reputation It’s essential to choose a manufacturer with a proven track record and extensive experience in producing HDPE fittings and components. An established company will likely have refined processes and better quality control measures.

2. Certifications Look for manufacturers that comply with international standards and possess the necessary certifications (such as ISO or ASTM). This ensures that the products meet safety and quality benchmarks.

3. Customization Options Different projects require different specifications. A good manufacturer should offer customization options to cater to unique project requirements, whether it’s the size, shape, or specific performance characteristics of the couplings.

4. Customer Support Reliable customer service is essential. Manufacturers that provide excellent support can assist with technical questions, product selection, and after-sales service, which can be invaluable during installation and maintenance.

5. Competitive Pricing While quality should never be compromised, comparing prices among different manufacturers can help identify a cost-effective option without sacrificing performance and reliability.

Conclusion

HDPE pipe couplings are vital components in modern piping systems, and the role of manufacturers in producing these couplings is critical. Choosing the right manufacturer ensures high-quality products that can enhance the efficiency and longevity of your piping systems. By considering factors such as experience, certifications, customization, customer support, and pricing, you can make an informed decision that meets your project needs. With the right HDPE pipe coupling manufacturers, you can ensure that your infrastructure is robust, reliable, and ready for the challenges of today and tomorrow.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025