Feb . 17, 2025 16:14 Back to list

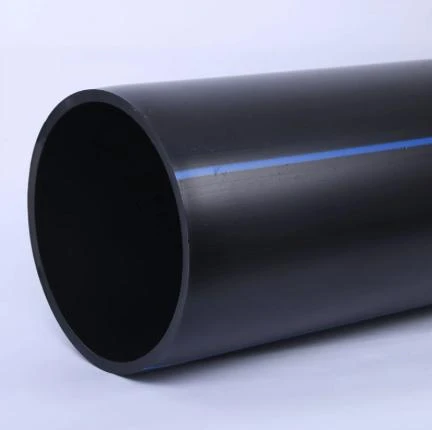

wholesale hdpe pipe price list

Authoritativeness in this domain requires acknowledging the regulatory landscape influencing HDPE pipe production and distribution. Compliance with international standards such as ASTM and ISO ensures that pipes meet necessary safety and quality benchmarks, influencing production costs. By selecting suppliers who adhere to these standards, businesses safeguard against future liabilities and align with best practices, enhancing trustworthiness and fostering long-term partnerships. Furthermore, building credibility involves leveraging real-world experiences to inform procurement strategies. Companies that have successfully navigated the HDPE pipe market often engage in direct communication with manufacturers, fostering relationships that can result in more favorable pricing terms and insights into upcoming market shifts. For instance, construction firms might share testimonials about projects where HDPE pipes significantly outperformed traditional materials, highlighting their adaptability in challenging environments. These narratives not only provide authentic endorsements of product capability but also build a reliable knowledge base for other industry players considering similar investments. Lastly, transparency and clarity in pricing are crucial for fostering trust within the market. Providing detailed price lists that break down costs by pipe dimensions, pressure ratings, and additional features allows customers to make informed decisions. Suppliers who prioritize openness and ease of access to pricing information are better positioned to build loyal client bases and gain a competitive edge. In conclusion, comprehending the wholesale price dynamics of HDPE pipes involves a multifaceted approach, balancing material and market considerations with technological advancements and regulatory compliance. By integrating these elements into their operational strategy, businesses can ensure that they align with best practices, optimize their procurement processes, and maximize the efficiency and longevity of their infrastructure projects. Insightful analysis, strategic planning, and steadfast adherence to industry standards will remain key to navigating the complexities of the HDPE pipe market successfully.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025