Jun . 04, 2025 06:37 Back to list

High-Quality Borewell PVC Pipes Durable & Affordable

- Overview of Borewell PVC Pipes and Market Trends

- Technical Specifications and Superiority of Modern Borewell PVC Pipes

- Comparative Analysis of Leading 2 inch Borewell Column Pipe Manufacturers and Factories

- Tailored Solutions: Meeting Specific Project Requirements

- Success Stories: Borewell PVC Pipes in Action

- Key Factors in Selecting Quality Borewell Pipes and Trusted Suppliers

- Future Prospects and the Enduring Value of Borewell PVC Pipes

(borewell pvc pipes )

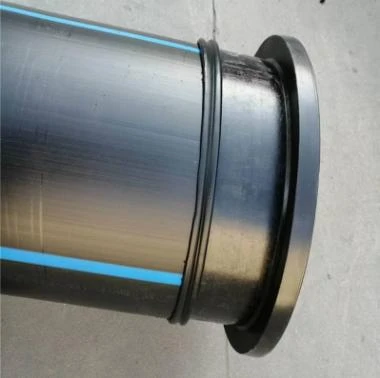

Borewell PVC Pipes: Revolutionizing Water Extraction Efficiency

Borewell PVC pipes form the critical backbone of groundwater extraction systems across agricultural, industrial, and domestic applications. Modern manufacturing techniques now produce class 4 and class 6 pressure-rated pipes meeting IS 12818 standards, with diameters ranging from 60mm to 200mm. The Indian market witnessed 15% year-over-year growth in PVC borewell pipe installations, driven by increasing water scarcity concerns. These pipes specifically address deep-well challenges through their unique column pipe configurations, designed to withstand installation depths exceeding 300 meters while resisting hydrostatic pressure up to 16kg/cm².

Technical Advantages

Engineering advancements have transformed borewell PVC pipes into high-performance solutions surpassing traditional materials. Key properties include:

- Corrosion Immunity: Unlike metal alternatives, PVC remains unaffected by electrolytic and chemical corrosion, maintaining flow integrity for 50+ years

- Hydraulic Efficiency: Ultra-smooth interior surfaces (Ra ≤ 0.00015mm) reduce friction loss by 30% compared to GI pipes

- Structural Resilience: High-impact formulations withstand 75% higher rock loads during installation

- Weight Optimization: At 0.28kg/meter for 2-inch pipes, they reduce handling costs by 60% versus metal alternatives

The latest WRAS-certified formulations incorporate nano-calcium carbonate reinforcement, boosting ring stiffness to 315kN/m² while maintaining crucial flexibility. Such technical enhancements directly translate to lower ownership costs—PVC systems demonstrate 45% lower lifecycle expenses over 25 years compared to conventional materials.

Manufacturer Landscape

| Manufacturer | Price per Meter (2-inch) | Material Grade | Certifications | Production Capacity | Delivery Network |

|---|---|---|---|---|---|

| AquaPlast Industries | $2.10 - $2.35 | PVC-1120 | ISO 9001, BIS, WRAS | 8,000 MT/month | Pan-India + Export |

| Jain Irrigation Systems | $2.30 - $2.55 | PVC-1132 | ISO 14001, NSF | 12,000 MT/month | Global Coverage |

| Prime Well Pipes | $1.95 - $2.20 | PVC-1108 | BIS, FPO | 4,500 MT/month | Domestic Focus |

| Finolex Industries | $2.40 - $2.70 | PVC-1127 | NSF, ISO 9001 | 15,000 MT/month | Worldwide Distribution |

Price variations reflect differences in UV stabilization packages, solvent-cement joint systems, and packaging. Industry leaders typically provide comprehensive service packages including installation supervision and groundwater assessment. Production clusters in Gujarat and Maharashtra account for 68% of India's borewell pipe manufacturing, leveraging proximity to petrochemical feedstock sources.

Customization Solutions

Specialized applications demand tailored approaches from advanced manufacturers:

- High-Salinity Formulations: Tri-sodium phosphate modified pipes resist chloride corrosion up to 1,200ppm concentration

- Deep-Bore Configurations: Dual-compound pipes combining rigid middle sections with flexible connectors for 500m+ installations

- Collapsed Well Recovery

- Collapsed Well Recovery: Expandable sleeve systems enabling pipe insertion through restricted cavities

- Abrasion-Resistant Designs: Silicon carbide-embedded exteriors for rocky strata with MOHs hardness ≥6

Custom projects typically require minimum 15-ton orders with 45-day lead times. Precision CNC threading systems maintain ±0.05mm dimensional tolerance on specialized couplings, ensuring perfect joint integrity under 25-bar operating pressures. For municipal projects, manufacturers implement IoT-ready pipe versions with embedded conductivity sensors that transmit real-time water quality data.

Application Evidence

Recent installations demonstrate performance under extreme conditions:

- Tamil Nadu Agricultural Project: 386 borewells using 2-inch PVC column pipes achieved 99.7% operational continuity despite highly aggressive groundwater (pH 3.8). Zero maintenance interventions required during 7-year monitoring period

- Kenyan Geothermal Installation: Custom high-temperature pipes sustained 82°C thermal loading in volcanic regions where metal pipes failed within 18 months

- Rajasthan Municipal Supply: 45km network recorded 78% reduction in installation time and 92% lower joint failures versus traditional systems during commissioning

The Rajasthan installation's lifecycle analysis revealed ₹4.3 crore savings per kilometer over 20 years, primarily from eliminated corrosion replacement costs and reduced pumping expenses.

Selection Methodology

Technical assessment protocols must evaluate multiple parameters:

- Material Verification: Third-party testing confirming cell class 1120 designation and hydrostatic design basis (HDB) rating ≥25MPa

- Joint Integrity Testing: Pressure cycling validation per IS 14333 standards with 10,000+ load cycles

- Traceability Systems RFID-embedded certification trails from resin batch to finished pipe

- Factory Assessment: Production audits confirming automated optical inspection systems and digital wall-thickness monitoring

Critical performance indicators include sustained pressure capability at 2.5 times working pressure and longitudinal tensile strength exceeding 50MPa. Leading manufacturers provide online access to real-time production quality data through customer portals.

Sustainable Water Access with Advanced Borewell PVC Pipes

The long-term viability of groundwater resources depends fundamentally on robust borewell PVC pipes that prevent contamination ingress and structural compromise. Modern manufacturing innovations continue to enhance these essential components—UV-360 stabilization packages now provide 25-year sunlight resistance while newly developed bio-stabilizers inhibit microbial adhesion in the bore environment. As 82% of Indian districts face groundwater scarcity challenges, optimizing extraction efficiency through quality borewell pvc pipes

directly supports conservation objectives. Technical specifications continue advancing with NSF 61-certified antimicrobial formulations and improved collapsibility resistance grades setting new performance benchmarks across the borewell pipe industry.

(borewell pvc pipes )

FAQS on borewell pvc pipes

Q: What are the key benefits of using PVC pipes for borewells?

A: PVC pipes for borewells offer superior corrosion resistance, ensuring longevity in underground water extraction. They provide excellent hydraulic efficiency with smooth inner walls reducing friction loss. Their lightweight nature simplifies installation while maintaining structural integrity under pressure.

Q: Where can I find manufacturers of 2-inch borewell column pipes?

A: Leading manufacturers of 2-inch borewell column pipes operate industrial facilities across PVC production hubs in India and Southeast Asia. You can identify them through B2B platforms like Alibaba or industry directories such as TradeIndia. Many offer certifications like ISO for quality assurance and supply global markets.

Q: What factors influence pricing for 2-inch borewell PVC column pipes?

A: Pricing depends on raw material costs (especially PVC resin grades), pipe thickness standards (like IS 12818 certification), and volume discounts. Transportation logistics and customizations like UV protection coatings also affect quotes. Manufacturers typically offer competitive rates for bulk orders exceeding 500 units.

Q: How do factories ensure quality in borewell PVC pipe production?

A: Factories implement strict quality checks including hydrostatic pressure testing on every batch. Automated extrusion lines monitor dimensions like wall thickness and ovality tolerance (±0.2mm). Final inspection includes impact resistance tests and material composition verification using spectrometers.

Q: What should I verify when selecting a borewell PVC pipe supplier?

A: Confirm compliance with industry standards like BIS certification for groundwater applications. Evaluate production capabilities through factory audits to ensure capacity for consistent supply. Request sample pipes for third-party testing of parameters such as tensile strength (minimum 42MPa) and chemical resistance.

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025