Feb . 14, 2025 03:57 Back to list

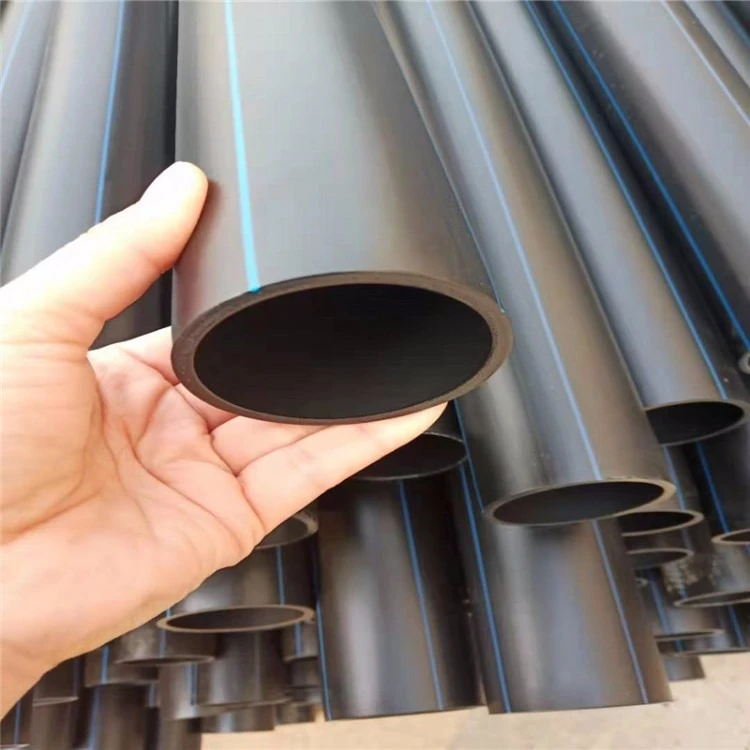

hdpe sprinkler pipe manufacturers

1. Pressure Rating The pipe must be chosen according to the pressure requirements of the system. The strength and durability of HDPE make it suitable for high-pressure applications. However, it’s crucial to select pipes that are rated to handle the expected loads to avoid accidents or system failures. 2. Environmental Compatibility HDPE pipes offer excellent chemical resistance, making them ideal for transporting hazardous materials. Understanding the environmental conditions, such as soil composition and weather patterns, can help in opting for a pipe that offers longevity and minimal maintenance. 3. Regulatory Compliance Staying informed about national and international standards governing the use of HDPE pipes ensures compliance and avoids legal repercussions. Industry certifications and adherence to standards such as ISO and ASTM are indicative of a reliable product. Establishing Authority and Trust in the HDPE Market Building a reputation in the HDPE market relies on consistent delivery of quality products, customer-centric services, and transparent business practices. Buyers are more inclined to trust suppliers who proactively share detailed product specifications, provide customer testimonials, and have a track record of timely deliveries. 1. Supplier Relationships Engaging with reputable manufacturers who uphold ethical practices can enhance a business’s credibility. An authoritative supplier will offer warranties, after-sales support, and technical guidance, contributing to a trusted buyer-seller relationship. 2. Innovative Solutions Encourage the use of innovative technologies that enhance the product's performance. Collaborations in research and development can lead to superior solutions that give a competitive edge. 3. Sustainability Initiatives As the industry moves towards sustainability, incorporating eco-friendly practices, such as recycling or offering products with a reduced carbon footprint, builds trust with consumers who prioritize environmental responsibility. In conclusion, the wholesale pricing of 63mm HDPE pipes is influenced by multiple factors encompassing raw material costs, manufacturing techniques, and market dynamics. By leveraging professional insights and ensuring product quality, businesses can make informed purchasing decisions that optimize their project outcomes while establishing a trustworthy presence in the industry.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025