Feb . 15, 2025 20:38 Back to list

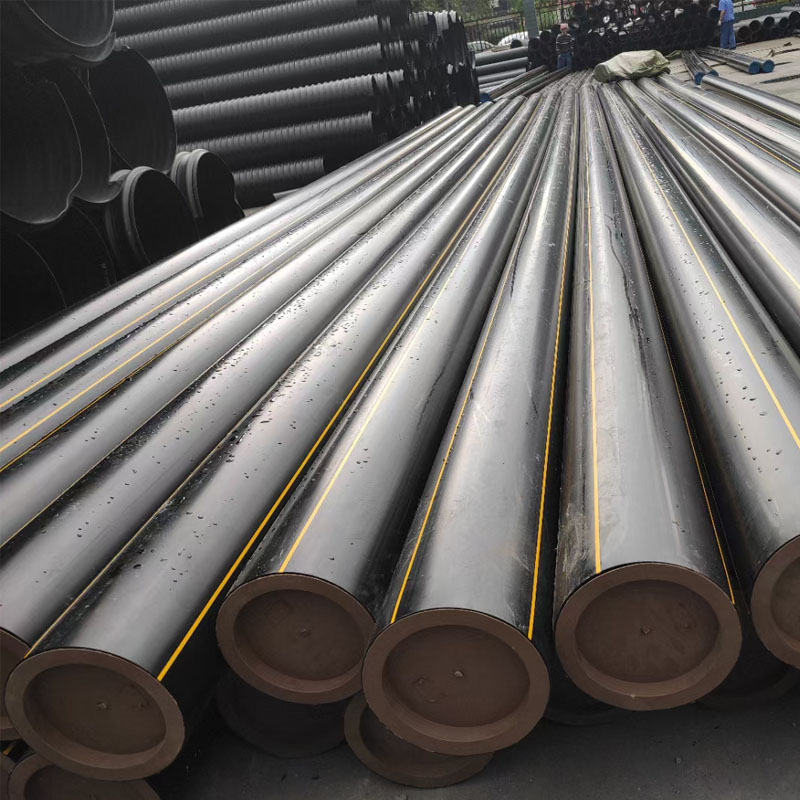

wholesale dn500 hdpe double wall corrugated pipe for sewage drain

Additionally, the corrosion resistance of DN500 HDPE pipes makes them particularly suitable for handling hazardous sewage contents without degradation. This attribute ensures consistent performance in various soil and climatic conditions, reinforcing the pipes' reliability over time. Notably, their resistance to biological growth lessens the risk of blockages common in many drainage systems, thereby enhancing overall system efficiency. Trustworthiness in HDPE pipe manufacturing is predominantly achieved through adherence to international quality standards. Suppliers offering wholesale DN500 HDPE pipes are typically certified, ensuring that their products maintain high quality and safety standards. This certification process involves rigorous testing under simulated environmental conditions, providing assurance of the pipes' performance before they reach the market. The application of DN500 HDPE double-wall corrugated pipes spans multiple sectors, from municipal sewage systems to industrial wastewater management. Their versatility and efficiency ensure they remain the preferred choice for both new installations and rehabilitation projects. Urban planners and civil engineers commend these pipes for facilitating rapid installation in urban environments, where disruptions must be minimized. Furthermore, the seamless integration of HDPE pipes into existing systems highlights their adaptability. Whether replacing aging infrastructure or connecting new developments to city networks, these pipes prove invaluable due to their compatibility with various jointing techniques, such as butt welding and electrofusion. In conclusion, the DN500 HDPE double-wall corrugated pipe represents a pinnacle of innovation in sewage drainage solutions. With compelling attributes of strength, sustainability, and adaptability, they remain indispensable in addressing the modern challenges of wastewater management. For wholesalers and project managers alike, the investment in these pipes guarantees resilience, cost-effectiveness, and an assurance of quality, positioning this product as a superior choice in the infrastructure arena.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025