Feb . 17, 2025 20:28 Back to list

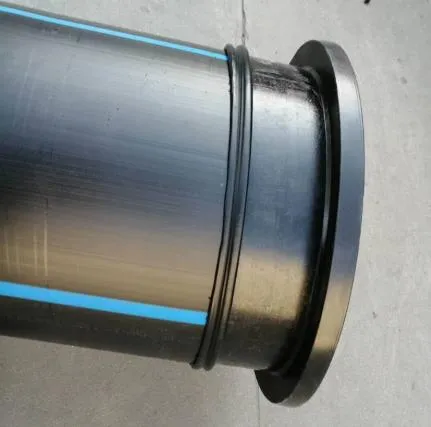

wholesale dn500

The logistics of purchasing wholesale DN500 components cannot be ignored. Transportation considerations such as weight, volume, and handling equipment determine shipping costs and feasibility. Supplier experience in accommodating logistical challenges—including customized inventory management and expedited shipping solutions—can make significant differences in project timelines and budgets. To truly leverage the benefits of DN500 wholesale procurement, partnerships with reputed manufacturers or distributors offering extensive after-sales support are indispensable. Effective after-sales service reduces downtime; consider suppliers committed to timely response and assistance, with capabilities for on-site support if necessary. Strategic alliances with leading suppliers and an in-depth understanding of market fluctuations—such as resin price changes affecting plastic-based pipes, or economic factors influencing metal prices—equip you with the foresight required to make financially sound decisions in DN500 procurement. In this ever-evolving industry, staying abreast of technological advances is vital. Developments in smart pipeline technology, integration with IoT devices for monitoring, or advancements in nondestructive testing methods may all present opportunities for operational efficiency enhancements. Knowledge in these areas will cement your role as an industry leader and a trusted resource for your network. In conclusion, while navigating the wholesale DN500 market can seem daunting, a grounded approach prioritizing expertise, quality assurance, and strategic relationships ensures robust, reliable procurement practices. This strategy not only solidifies your standing in the industry but also enhances the efficiency and effectiveness of your operations, paving the way for long-term success.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025