Dec . 25, 2024 15:39 Back to list

Top HDPE Pipe Manufacturers for Reliable Water Supply Solutions

The Role of HDPE Pipe Manufacturers in Water Supply Solutions

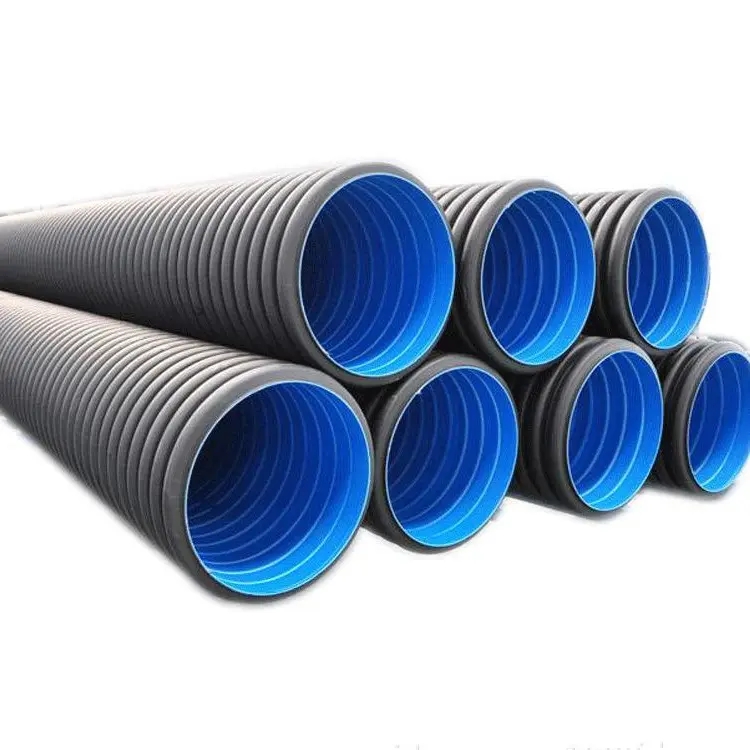

High-Density Polyethylene (HDPE) pipes have revolutionized the infrastructure of water supply systems across the globe. With their robust construction, impressive versatility, and significant cost-effectiveness, HDPE pipes manufactured by specialized companies are an integral part of modern water management projects. This article will explore the critical role that HDPE pipe manufacturers play in ensuring sustainable and efficient water supply solutions.

Advantages of HDPE Pipes

One of the primary reasons HDPE pipes are favored in water infrastructure is their durability. HDPE is a thermoplastic polymer known for its high tensile strength and flexibility. These pipes are resistant to corrosion, chemicals, and UV rays, which makes them ideal for long-term use in various environmental conditions. Moreover, HDPE pipes boast a longer lifespan, often exceeding 50 years with minimal maintenance.

Another key advantage is their lightweight nature, which simplifies transportation and installation. This attribute not only reduces labor costs but also enables quicker project execution. With seamless joints and less risk of leakage compared to traditional piping materials, HDPE pipes contribute significantly to conserving water resources.

Manufacturing Process of HDPE Pipes

The manufacturing process of HDPE pipes involves several critical steps that ensure the final product meets high-quality standards. Initially, raw HDPE resin is melted and extruded through a die to form pipes of different diameters and lengths. The extruded pipes are then cooled and cut to the desired size before being subjected to rigorous quality control tests.

Leading HDPE pipe manufacturers utilize advanced technology to maintain consistent quality throughout the production process. The integration of automation and real-time monitoring systems ensures that every batch produced adheres to industry standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). These manufacturers also focus on sustainability, employing eco-friendly practices in both sourcing and production.

water supply hdpe pipe manufacturers

The Impact of HDPE Pipe Manufacturers on Water Supply Projects

HDPE pipe manufacturers play a crucial role in sustaining the world’s water resources by providing solutions that not only enhance the efficiency of water distribution but also promote conservation. With urbanization and climate change placing unprecedented stress on water supply systems, the demand for reliable piping solutions has surged. Manufacturers are responding by innovating their product lines and offering customized solutions to cater to specific project requirements.

Collaborating closely with engineers, contractors, and municipal planners, HDPE pipe manufacturers help design integrated water supply systems that minimize wastage and maximize delivery efficiency. Their expertise in high-quality materials ensures that infrastructures are resilient to natural disasters, public health issues, and the impacts of climate change.

Future Developments in HDPE Pipe Manufacturing

As technology continues to advance, the HDPE pipe manufacturing industry is evolving with new developments that aim to further enhance the functionality and performance of these pipes. Innovations in additives, recycling processes, and jointing technologies are key areas of research and development. For instance, the introduction of advanced fittings and joining methods may reduce installation time and improve pipe integrity.

Moreover, as environmental concerns grow, manufacturers are increasingly focusing on producing recyclable and biodegradable materials. This commitment to sustainable practices not only fulfills regulatory requirements but also responds to consumer demand for green products.

Conclusion

In conclusion, HDPE pipe manufacturers are fundamental to optimizing water supply systems around the world. Their dedication to producing durable, efficient, and sustainable piping solutions is essential for meeting the challenges posed by contemporary water management. As the industry continues to innovate, the collaboration between manufacturers and other stakeholders will be critical in ensuring the resilience and effectiveness of global water infrastructure. Investing in HDPE technology is not merely a choice but a necessity for a sustainable future.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025