Dec . 09, 2024 18:02 Back to list

HDPE Pipe Manufacturing for Efficient Water Supply Solutions in Diverse Applications

The Role of HDPE Pipes in Water Supply Systems

Water is an essential resource for human survival, agricultural productivity, and industrial activities. The efficient distribution of this precious commodity relies heavily on a robust infrastructure, where the choice of piping materials plays a crucial role. Among various options, High-Density Polyethylene (HDPE) pipes have emerged as a preferred choice for water supply systems due to their numerous advantages. This article explores the benefits of HDPE pipes, their manufacturing processes, and their implications for sustainable water management.

Understanding HDPE Pipes

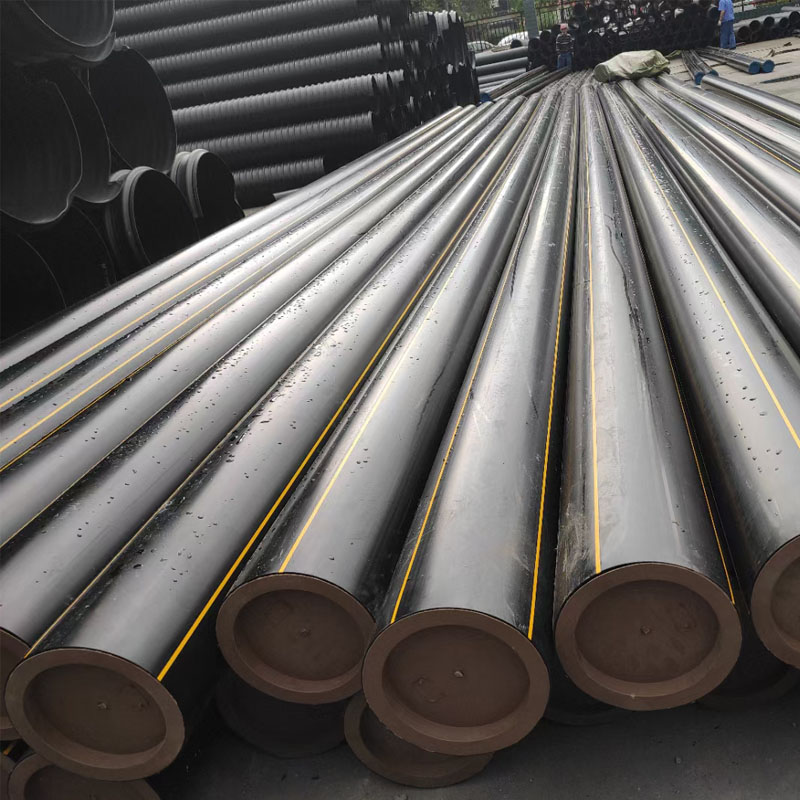

HDPE pipes are made from high-density polyethylene, a thermoplastic polymer known for its high strength-to-density ratio. These pipes are lightweight, flexible, and resistant to various chemicals, making them ideal for transporting potable water as well as wastewater and stormwater. The durability of HDPE pipes is a crucial factor for municipal water supply systems, where longevity and reliability are paramount.

Advantages of HDPE Pipes

1. Durability and Longevity HDPE pipes are highly resistant to corrosion, chemicals, and environmental stressors. When properly installed, these pipes can last for over 50 years, significantly reducing the need for frequent replacements. This characteristic is particularly beneficial in regions with harsh environmental conditions.

2. Flexible and Lightweight The flexibility of HDPE pipes allows for easy installation even in challenging terrains. Their lightweight nature reduces transportation costs and simplifies handling during installation. Moreover, less heavy equipment is required during the installation process, leading to lower overall project expenses.

3. Joint Integrity HDPE pipes can be joined using various methods, including heat fusion, electrofusion, and mechanical fittings. The fusion process creates a seamless joint, which enhances the pipe's overall strength and reduces the risk of leaks. This aspect is vital for maintaining the quality of the water being transported and minimizing groundwater contamination.

water supply hdpe pipe factory

4. Low Maintenance Costs Due to their inherent resistance to corrosion and the absence of rusting, HDPE pipes require significantly less maintenance compared to traditional materials like metal or concrete. This results in lower operational costs for water supply facilities, freeing up resources for other critical infrastructure projects.

5. Environmental Impact The production of HDPE pipes involves less energy consumption compared to other materials, making them an eco-friendlier option. Furthermore, they are fully recyclable, contributing to a circular economy. By choosing HDPE pipes, municipalities can reduce their carbon footprint and promote sustainable water management practices.

The Manufacturing Process of HDPE Pipes

The production of HDPE pipes involves several steps, starting with the polymerization of ethylene, which is sourced from petroleum. The polymer is then processed and extruded into pipe form. Quality control measures are implemented throughout the manufacturing process to ensure the pipes meet industry standards and regulations.

Manufacturers often utilize advanced technologies to produce HDPE pipes of various diameters and thicknesses tailored to specific applications. Stringent testing ensures that the pipes can withstand the pressures associated with water distribution systems.

Conclusion

As the demand for clean and reliable water supply continues to grow, the importance of efficient pipeline systems cannot be overstated. HDPE pipes represent a significant advancement in water supply infrastructure, offering a blend of durability, flexibility, and cost-effectiveness. Their environmental benefits and low maintenance requirements position them as a sustainable option for modern water distribution.

In an era where water scarcity is becoming a pressing issue, investing in HDPE piping systems is not just a choice; it is a necessity for ensuring access to safe and clean water for future generations. As communities and governments seek to modernize their water supply networks, HDPE pipes will undoubtedly play a vital role in shaping a sustainable future.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025