Dec . 05, 2024 16:40 Back to list

use of ppr pipe factory

The Use of PPR Pipes in Modern Construction A Comprehensive Analysis

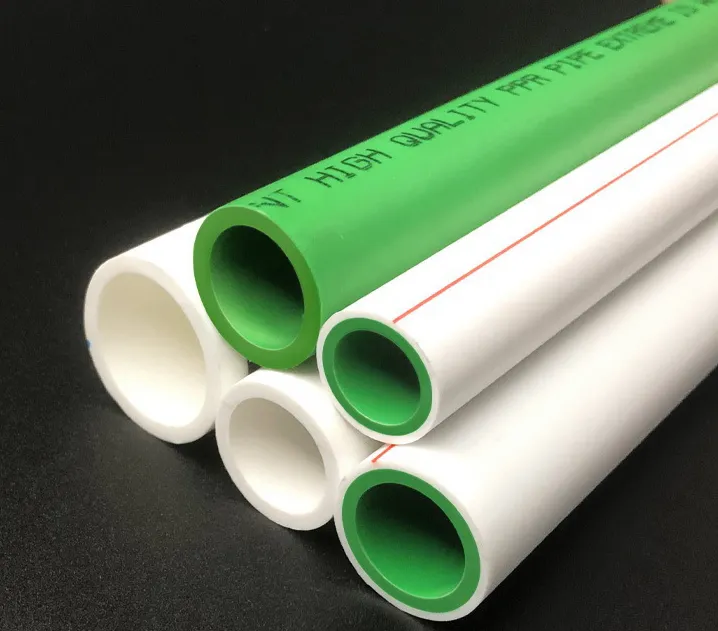

In recent years, the construction industry has seen a significant evolution in the materials used for plumbing and piping systems. Among these materials, Polypropylene Random Copolymer (PPR) has emerged as a preferred choice for many builders and engineers. Its unique properties and benefits make it highly suitable for diverse applications, particularly in water supply systems. This article explores the use of PPR pipes in detail, highlighting their advantages, applications, and considerations for factory production.

Understanding PPR Pipes

PPR pipes are made from a thermoplastic polymer, specifically a copolymer of polypropylene. Known for their excellent durability, resistance to corrosion, and ease of installation, PPR pipes are increasingly utilized in both residential and industrial environments. The production process involves extracting and polymerizing propylene gas, resulting in a lightweight yet robust piping solution that can withstand high temperatures and pressures.

Advantages of PPR Pipes

1. Durability and Longevity One of the most significant advantages of PPR pipes is their durability. Unlike traditional metal pipes, PPR does not corrode or scale, ensuring a long lifespan that often exceeds 50 years. This quality minimizes maintenance costs and reduces the frequency of replacements.

2. Temperature Resistance PPR pipes can handle temperatures ranging from -20°C to 95°C. This makes them suitable for hot and cold water supply systems, including heating systems, without fear of deformation or leakage.

3. Chemical Resistance The non-reactive nature of PPR makes it resistant to a wide range of chemicals, making it ideal for industrial applications where toxic substances may be involved.

4. Lightweight and Easy to Install PPR pipes are significantly lighter than metal alternatives, which simplifies transportation and installation processes. This attribute not only reduces labor costs but also makes it easier for builders to handle the materials on-site.

5. Good Insulation Properties PPR pipes have excellent thermal insulation properties, reducing heat loss in hot water systems and ensuring that the water stays at the desired temperature for longer periods.

use of ppr pipe factory

6. Environmental Impact PPR pipes are an environmentally friendly option, as they are recyclable and do not release harmful substances into the ecosystem. Their production also uses less energy compared to traditional piping systems made from metals.

Applications of PPR Pipes

The versatility of PPR pipes allows them to be used in various applications, including

- Residential Plumbing PPR pipes are increasingly popular for residential plumbing systems, providing reliable hot and cold water supply lines. - Heating Systems Their ability to withstand high temperatures makes PPR pipes suitable for underfloor heating and radiator systems. - Industrial Applications Many industries, including automotive and chemical processing, use PPR pipes due to their chemical resistance and durability. - Irrigation Systems In agricultural settings, PPR pipes are used for irrigation systems because they can convey water efficiently without deteriorating.

Considerations for Factory Production

To maximize the benefits of PPR pipes, it is essential for manufacturers to adhere to strict production standards. The quality of the raw materials used during manufacturing plays a critical role in the final product's performance. Additionally, factories should implement quality control measures to ensure that each batch of pipes conforms to the relevant industry standards and specifications.

Moreover, as the demand for PPR pipes rises, factories need to invest in modern technologies and machinery to enhance production efficiency. This investment not only ensures a consistent supply but also allows for the development of innovations such as multilayered pipes that offer even greater benefits.

Conclusion

In conclusion, the use of PPR pipes in modern construction is a testament to the advancements in materials science and engineering. Their durability, chemical resistance, and ease of installation position them as a superior alternative to traditional piping systems. With continued innovation in manufacturing processes, PPR pipes are set to become an even more integral part of plumbing and piping solutions across various sectors. As the industry evolves, embracing sustainable and efficient materials like PPR will promote not only economic benefits but also a healthier environment for future generations.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025