Aug . 01, 2024 05:26 Back to list

Understanding the Various Sizes of HDPE Corrugated Pipes for Optimal Industrial Applications

Understanding HDPE Corrugated Pipe Sizes and Their Factory Production

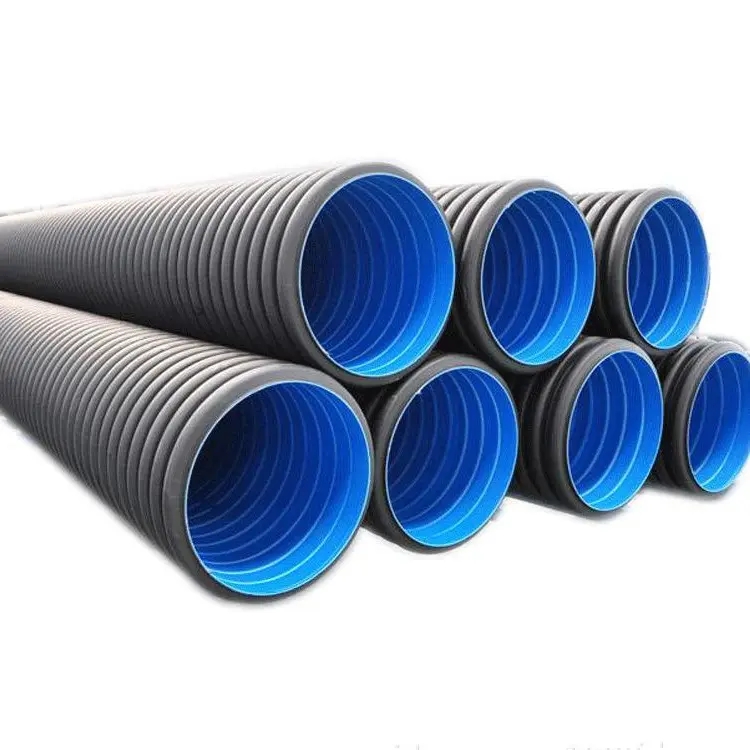

High-Density Polyethylene (HDPE) corrugated pipes have become a staple in modern infrastructure projects due to their durability, flexibility, and corrosion resistance. These pipes are widely used for drainage, stormwater management, and other applications where efficient fluid transport is crucial. This article explores the various sizes of HDPE corrugated pipes manufactured in factories and their specific applications, ensuring that engineering professionals and contractors can make informed decisions.

What is HDPE Corrugated Pipe?

HDPE corrugated pipe is made from high-density polyethylene, a thermoplastic known for its strong molecular structure. This design provides high tensile strength while remaining lightweight. The pipe features a unique corrugated profile that enhances its load-bearing capabilities and resistance to crushing forces. This structure provides an ideal balance between flexibility and durability, making HDPE corrugated pipes suitable for various environments, including agricultural, urban, and industrial settings.

Standard Sizes of HDPE Corrugated Pipes

HDPE corrugated pipes come in various sizes, with diameters usually ranging from 4 inches to 60 inches. The selection of pipe size depends on the specific application and flow requirements.

1. Nominal Diameter The diameter of HDPE pipes is often referred to as the nominal diameter (DN). Common sizes include - Small diameter pipes 4, 6, 8, 10 - Medium diameter pipes 12, 15, 18, 24 - Large diameter pipes 30, 36, 48, 60

2. Wall Thickness The thickness of the pipe walls varies, affecting the pipe's load-bearing capacity and strength. Typical standards are classified to meet different demands, including light duty, medium duty, and heavy-duty applications.

3. Length HDPE corrugated pipes are generally available in 20-foot lengths. However, custom lengths can often be manufactured based on project requirements. Factory settings allow for cut-to-length services, accommodating specific project guidelines.

hdpe corrugated pipe sizes factory

Production of HDPE Corrugated Pipes in Factories

The production of HDPE corrugated pipes takes place in specialized factories equipped with advanced manufacturing technologies. The process begins with the extrusion of HDPE pellets, which are heated until they melt and form a continuous pipe.

- Extrusion Process The extruder shapes the molten HDPE into a tube that is then passed through a mold, creating the corrugated profile. The cooling phase follows where water or air cools the newly formed pipe.

- Quality Control Factories implement rigorous testing procedures to ensure that the pipes meet industry standards. Tests may include checking for pressure resistance, flexibility, and wall thickness. Such quality checks are vital to ensure that the pipes can withstand environmental stresses.

- Custom Sizes and Specifications Many factories offer customization options for pipe sizes, wall thicknesses, and lengths according to client specifications. This flexibility is especially beneficial for large-scale projects that require tailored solutions.

Applications of HDPE Corrugated Pipes

HDPE corrugated pipes find extensive use in various sectors - Drainage Systems Commonly used in agricultural fields, highways, and urban drainage systems to manage excess water efficiently. - Septic Systems These pipes are ideal for conveying wastewater in septic systems due to their resistance to chemicals and durability. - Stormwater Management Used in detention and retention systems to control stormwater runoff effectively.

Conclusion

The versatility of HDPE corrugated pipes, combined with the range of available sizes produced in factories, makes them an excellent choice for a variety of applications. Understanding the specifications and production methods of these pipes allows engineers and contractors to select the best materials for their projects, leading to more effective and sustainable infrastructure solutions. As the construction industry continues evolving, the demand for high-quality HDPE corrugated pipes will undoubtedly grow.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025