Aug . 10, 2024 02:50 Back to list

Understanding the Importance of Outside Diameter Measurements for PVC Pipe Products in Construction

Understanding the Importance of Outside Diameter in PVC Pipe Products

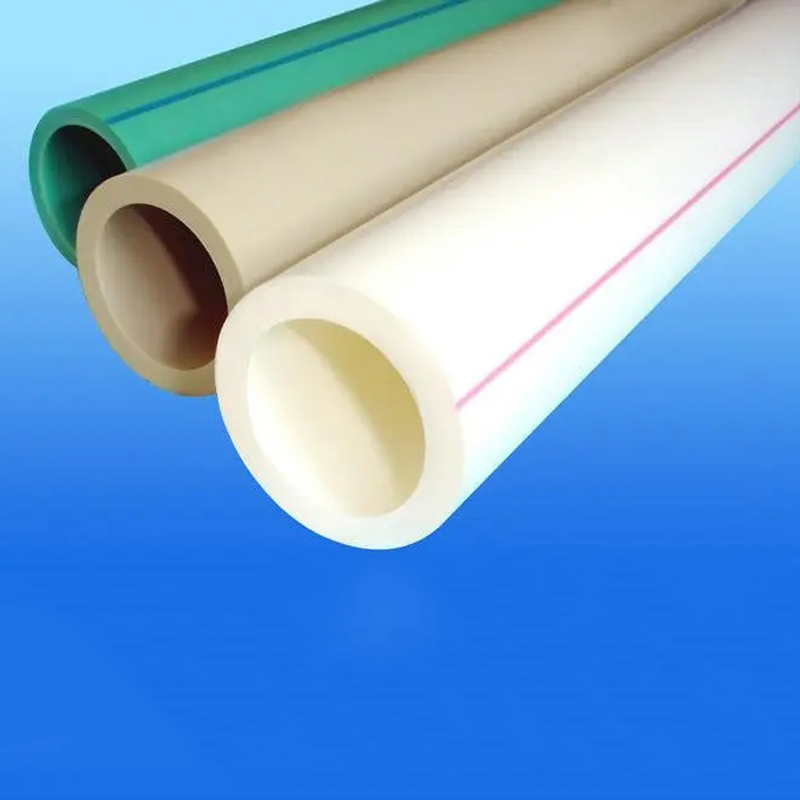

Polyvinyl chloride (PVC) pipe has become an essential material in various industries, including construction, plumbing, and irrigation, due to its durability, lightweight properties, and resistance to corrosion. One of the critical specifications when selecting PVC pipes is the outside diameter (OD), which plays a significant role in the overall performance and suitability of the product for specific applications.

The outside diameter of a PVC pipe refers to the distance across the pipe measured from one outer edge to the opposite edge, encompassing the pipe's complete structure. This measurement is integral to the design and functionality of the piping system, influencing compatibility with fittings, flow rates, and even installation processes. When selecting PVC pipes, it is crucial to consider the outside diameter alongside other parameters such as wall thickness and internal diameter.

Industry Standards and Sizing

PVC pipes are manufactured according to various industry standards, making it easier for engineers and contractors to select the appropriate materials for their projects. The American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM) provide guidelines that dictate the dimensions and tolerances for PVC pipes. These standards ensure that pipes produced by different manufacturers maintain consistent sizing, allowing for interoperability between various components.

Outside diameter sizes can vary depending on the application. For instance, standard residential plumbing may use a 1-inch or 2-inch OD pipe, while larger diameter pipes—such as those used in municipal applications—can reach 12 inches or more. The choice of diameter impacts not only the volume of fluid that can pass through the pipe but also the pressure ratings and connection types used in the piping system.

outside diameter of pvc pipe product

Implications of Outside Diameter on Performance

The outside diameter of PVC pipes has direct implications for their performance. A larger diameter allows for higher flow rates, which is crucial in systems that transport substantial volumes of water or sewage. Conversely, smaller diameters are better suited for applications that require precision and controlled flow. Additionally, the outside diameter impacts the pressure rating of the pipe. Thicker-walled pipes with larger outside diameters can better withstand high-pressure environments, making them preferable for heavy-duty industrial uses.

Furthermore, the compatibility of PVC pipes with fittings and connections is heavily influenced by the outside diameter. Inadequate matching of diameters can lead to leaks, joint failures, and compromised system integrity. Therefore, it is vital to ensure that all components in a piping system are compatible in terms of sizing.

Installation Considerations

From an installation perspective, knowing the outside diameter of PVC pipes aids in planning and executing the piping layout. It allows installers to determine the appropriate supports, joints, and fittings required for a stable and secure system. The installation process also varies depending on the outside diameter, as larger pipes may require additional labor and equipment for handling and connection.

In summary, the outside diameter of PVC pipe products is a fundamental design parameter that significantly influences their application, performance, and installation. Understanding its implications enables engineers, contractors, and homeowners to make informed decisions when selecting the appropriate PVC pipe for their specific needs. As the demand for reliable and efficient piping systems continues to grow, recognizing the critical role of outside diameter in PVC pipe specifications will remain an essential aspect of successful project execution.

-

UPVC Column Pipes for Submersible Pumps: Durable & Corrosion-Free

NewsAug.27,2025

-

Premium DN50 HDPE Pipes in Coils: Flexible, Long-lasting Supply

NewsAug.26,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Solutions

NewsAug.25,2025

-

Hot/Cold DN25 PPR Water Pipes for Kitchen | Durable & Food-Safe

NewsAug.24,2025

-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

NewsAug.21,2025