Nov . 13, 2024 08:05 Back to list

type of ppr pipe factory

Types of PPR Pipe Factory An Overview

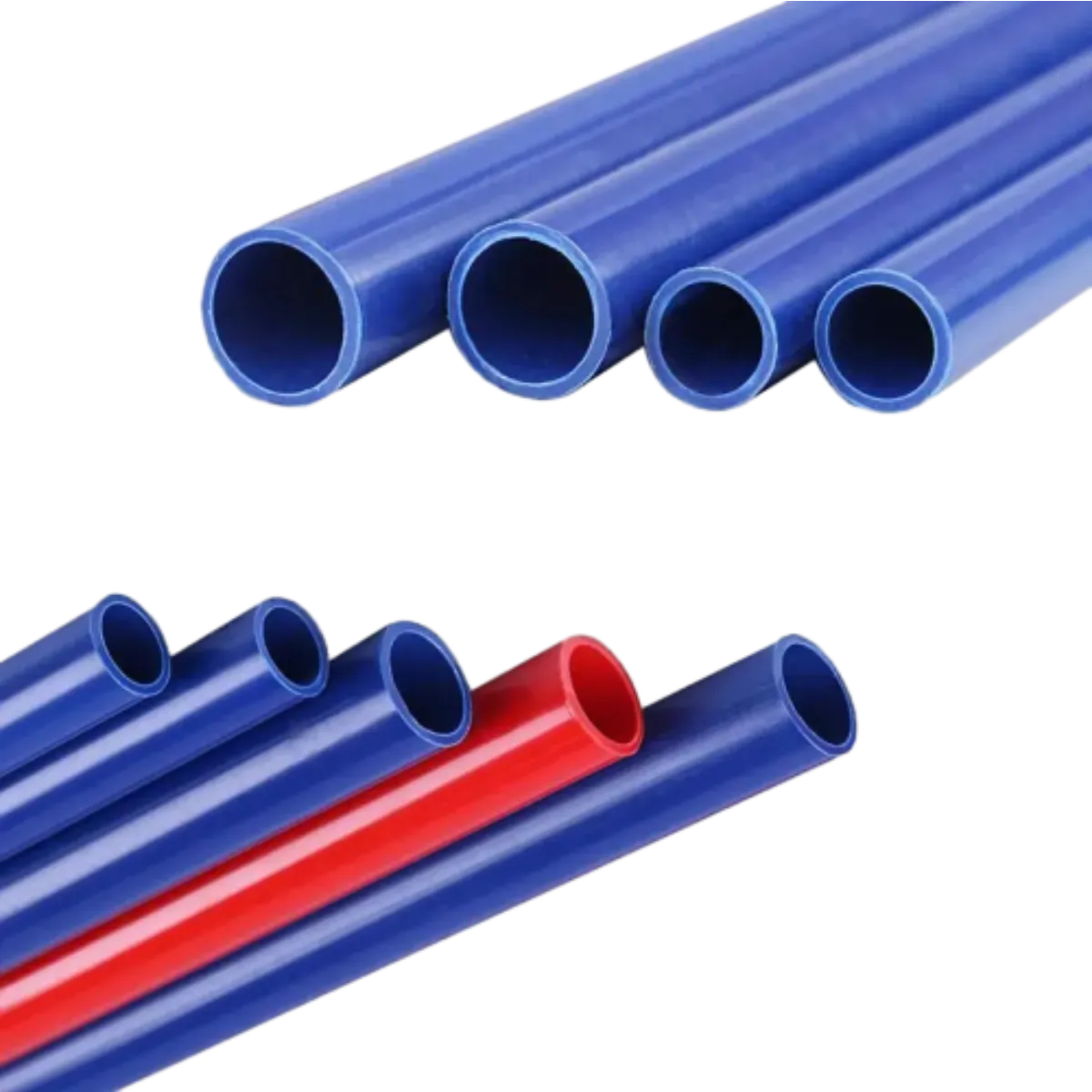

PPR (Polypropylene Random Copolymer) pipes have become increasingly popular in various sectors, including plumbing, heating, and cooling systems, owing to their durability, chemical resistance, and cost-effectiveness. The PPR pipe factory plays a crucial role in the production of these essential components, offering various types tailored for specific applications.

PPR pipes are primarily manufactured in different pressure ratings, sizes, and colors. The most common types include

Types of PPR Pipe Factory An Overview

2. PPR Pipe Fittings In addition to the pipes themselves, a wide range of fittings, including elbows, tees, couplings, and valves, are produced in PPR pipe factories. These fittings are essential for creating a complete piping system, enabling changes in direction, branching, or connecting to other systems.

type of ppr pipe factory

3. Glass Fiber Reinforced PPR Pipes This advanced type incorporates glass fibers into the polypropylene matrix, enhancing the pipe's strength and thermal stability. These pipes are ideal for applications requiring higher pressure tolerance and temperature variations, making them suitable for industrial settings or regions with extreme climates.

4. Anti-Static PPR Pipes As industries increasingly focus on safety, especially in environments where flammable gases may be present, anti-static PPR pipes have gained popularity. These pipes are designed to prevent the accumulation of static electricity, reducing fire hazards.

Inside a PPR pipe factory, advanced machinery and technology are utilized to ensure the precision and quality of the pipes produced. Automated extrusion lines, injection molding machines, and rigorous quality control measures are essential components of the manufacturing process. Factories often employ skilled technicians who oversee these operations, ensuring compliance with international standards.

To cater to the ever-growing demand for PPR pipes, many factories are adopting environmentally friendly practices. This includes recycling waste materials, using energy-efficient machinery, and implementing sustainable production methods. Such initiatives not only reduce the environmental impact but also enhance the brand reputation of the manufacturers.

In conclusion, the variety of PPR pipes and fittings produced in a PPR pipe factory caters to a wide range of applications, making them an essential part of modern infrastructure. By focusing on quality, innovation, and sustainability, these factories continue to play a vital role in meeting global plumbing needs.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025