Nov . 06, 2024 19:47 Back to list

type of hdpe pipe service

Understanding the Types of HDPE Pipe Services

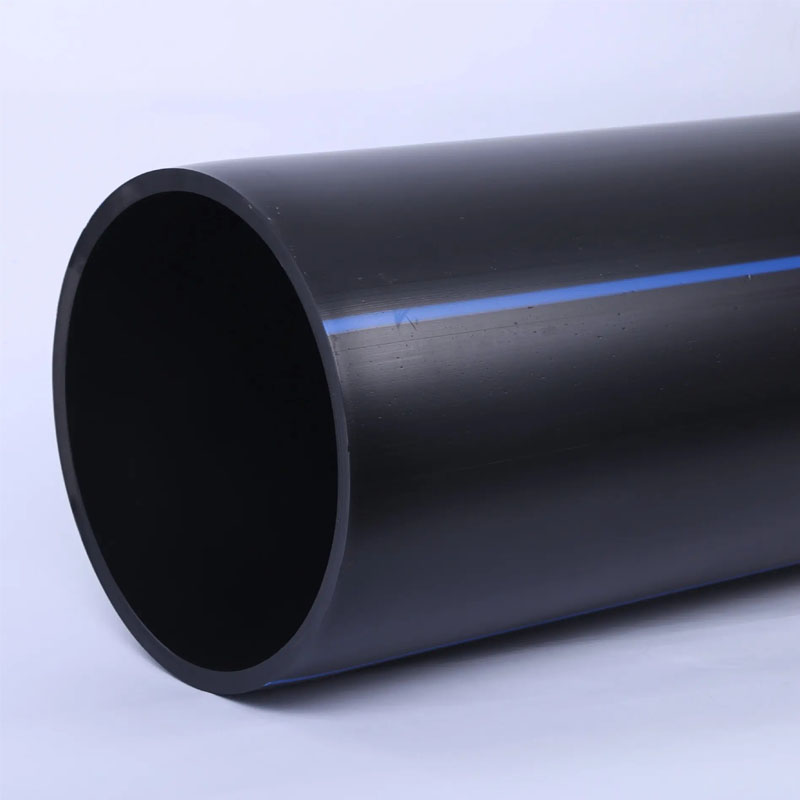

High-Density Polyethylene (HDPE) pipes have become increasingly popular in various industries due to their unique properties and versatility. This thermoplastic polymer is known for its strength, durability, and resistance to corrosion, making it an ideal choice for a wide range of applications, from water supply to gas distribution. In this article, we will explore the different types of services associated with HDPE pipes and their relevant applications.

1. Water Supply Systems

One of the most common uses of HDPE pipes is in municipal water supply systems. These pipes are ideal for transporting potable water due to their non-toxic nature and resistance to bacterial growth. HDPE pipes are also less prone to leaking compared to traditional materials like metal or concrete. The flexibility of HDPE allows for easier installation around obstacles, reducing the need for extensive excavation work. Services available for water supply systems include pipe installation, maintenance, and leak detection.

2. Sewage and Wastewater Management

HDPE pipes are equally important in sewage and wastewater systems. Their resistance to corrosive substances makes them suitable for transporting sewage and industrial effluents. Additionally, these pipes can handle higher flow rates, which is critical in preventing blockages and maintaining efficient wastewater treatment processes. Service offerings in this area typically include the installation of pipe systems, rehabilitative services for aging infrastructure, and routine inspections to ensure optimal performance.

3. Industrial Applications

type of hdpe pipe service

In industrial settings, HDPE pipes are used for various applications, such as chemical processing, mining, and irrigation. The pipes can withstand high temperatures and pressures, making them suitable for transporting aggressive chemicals and materials. Companies providing industrial HDPE services often offer custom solutions, including pipe fabrication, specialized fittings, and corrosion-resistant coatings tailored to specific industry requirements.

4. Gas Distribution

HDPE pipes are also extensively used in the distribution of natural gas. Due to their robustness and ability to resist stress fractures, they are a preferred choice for both underground and above-ground gas lines. The services associated with gas distribution include the installation of HDPE piping systems, regular inspections, and safety audits to ensure compliance with regulatory standards.

5. Telecommunications and Electrical Conduits

In addition to fluid transportation, HDPE pipes are increasingly used as conduits for telecommunications and electrical cables. Their smooth inner surfaces reduce friction and promote efficient cable installation. Service providers in this sector often specialize in trenchless installation techniques, which minimize surface disruption and reduce installation costs.

Conclusion

The versatility of HDPE pipes allows them to serve multiple industries, providing effective solutions for water supply, wastewater management, industrial applications, gas distribution, and telecommunications. As the demand for safe and efficient piping materials continues to rise, the services related to HDPE pipe installation and maintenance will play a critical role in ensuring the longevity and reliability of infrastructure. Organizations looking to utilize HDPE pipes should consider partnering with experienced service providers to leverage their expertise and achieve successful project outcomes.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025