Jul . 12, 2024 13:30 Back to list

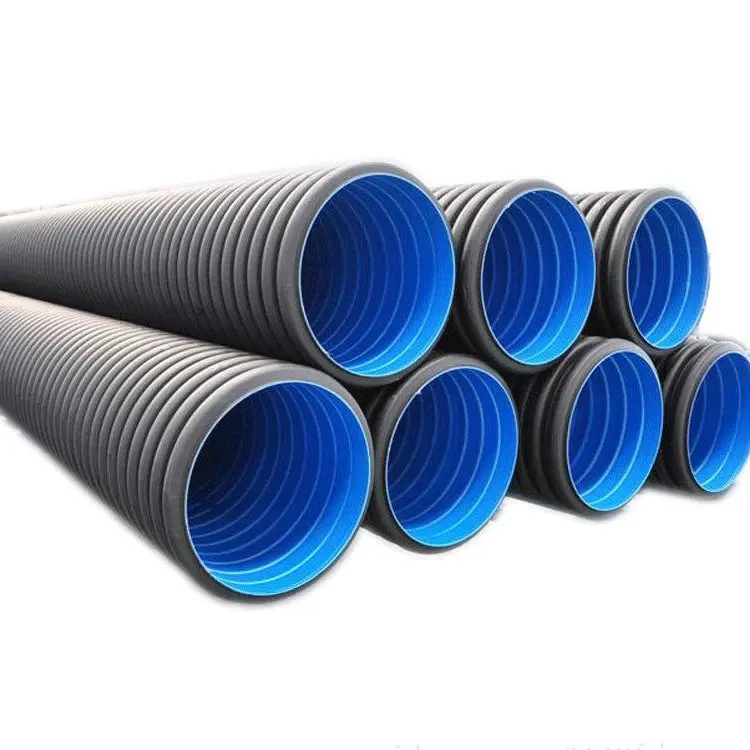

Top HDPE pipe manufacturers offering a variety of products for different applications

hdpe pipe pdf manufacturers. HDPE pipes are able to withstand harsh environmental conditions, making them suitable for use in both above-ground and underground installations. This resistance to abrasion and impact ensures the integrity of the pipe and reduces the risk of leaks and failures. Furthermore, HDPE pipes are highly resistant to chemicals, making them suitable for handling a wide range of substances without compromising the pipe's structural integrity. This chemical resistance also makes HDPE pipes suitable for use in industrial applications where exposure to corrosive materials is common. HDPE pipe manufacturers produce pipes in a variety of sizes and pressure ratings to meet the specific needs of different applications. They also offer a range of fittings and accessories to facilitate the installation and connection of HDPE pipes in various configurations. In conclusion, HDPE pipes offer a reliable and cost-effective solution for a wide range of piping needs in various industries. With their durability, flexibility, lightweight design, and chemical resistance, HDPE pipes have become the preferred choice for many contractors and engineers. As the demand for HDPE pipes continues to grow, the number of HDPE pipe manufacturers is expected to increase, providing customers with more options and ensuring a steady supply of high-quality pipes for their projects.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025