Nov . 09, 2024 11:33 Back to list

Submersible Pump Column Pipe Maintenance and Operational Guidelines for Optimal Performance

The Importance of Submersible Pump Column Pipe Service

Submersible pumps are essential components in various water extraction and management systems, offering efficiency and reliability. These pumps are designed to be submerged in the fluid they are pumping, making them ideal for applications such as groundwater extraction, sewage pumping, and irrigation. However, for these pumps to function optimally, the column pipe that connects them to the surface plays a crucial role.

The column pipe serves as the conduit through which the pumped fluid travels from the submersible pump to the surface. Its proper installation and maintenance are vital for the overall efficiency and longevity of the submersible pump system. A failure in the column pipe can lead to significant issues, including reduced pump performance, increased energy consumption, and ultimately, costly downtimes for repairs or replacements.

Key Functions of the Column Pipe

1. Fluid Transport The primary function of the column pipe is to transport water or other fluids from the pump to the discharge point above ground. The pipe must be appropriately sized to accommodate the flow rate required by the system while minimizing friction losses.

2. Structural Support The column pipe provides necessary support for the submersible pump, ensuring that it remains securely in place within the well or borehole. This structural integrity is essential, especially in deep installations, where significant weight and pressure exerted by the water can lead to shifting or damage if not properly secured.

3. Pressure Management When a submersible pump operates, it generates pressure within the system. The column pipe must be able to withstand this pressure without deforming or rupturing. Choosing the right materials and thickness for the column pipe is crucial to ensure it can handle the pressure without compromising its integrity.

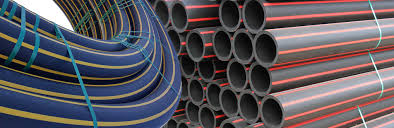

4. Protection from Corrosion Depending on the application, the water being pumped may contain corrosive elements that could deteriorate the column pipe over time. Selecting materials that are resistant to corrosion—such as stainless steel or high-density polyethylene—can greatly extend the life of the column pipe and, in turn, the pump itself.

submersible pump column pipe service

Regular Maintenance and Services

To ensure the reliability of the submersible pump system, regular maintenance of the column pipe is essential

. Here are some key maintenance practices1. Inspection Periodic visual inspections can help identify any signs of wear, corrosion, or leaks in the column pipe. Early detection of issues can save time and expense in repairs.

2. Cleaning Sediment and debris can accumulate in the column pipe over time, potentially restricting flow and reducing pump efficiency. Regular cleaning can help maintain optimal flow rates.

3. Pressure Testing Conducting pressure tests can help verify that the column pipe is functioning correctly and can handle the operational pressures generated by the submersible pump.

4. Replacement If any significant damage or wear is detected during inspections or cleaning, timely replacement of damaged sections of the column pipe is crucial to prevent failures that could lead to operational downtime.

Conclusion

The column pipe service associated with submersible pumps is critical to the efficiency and reliability of fluid transport systems. Proper maintenance, material selection, and regular inspections are key components to ensure that both the column pipe and the submersible pump perform optimally over their lifespan. Investing in routine service will not only enhance the performance of the pump system but also help ensure seamless operations, ultimately leading to cost savings and reduced downtime in critical applications. By prioritizing the health of the column pipe, users can enjoy the benefits of their submersible pump systems with peace of mind.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025