Oct . 13, 2024 16:18 Back to list

Submersible Pump Column Pipe Manufacturing Solutions for Efficient Water Systems

Understanding Submersible Pump Column Pipe Manufacturing

In the world of fluid transportation, submersible pumps play a crucial role, particularly in applications such as dewatering, sewage treatment, and groundwater extraction. These pumps operate underwater, and to effectively manage the fluid they pump, a critical component is the column pipe. This article will provide an insight into the manufacturing processes and considerations associated with submersible pump column pipes.

What Are Submersible Pump Column Pipes?

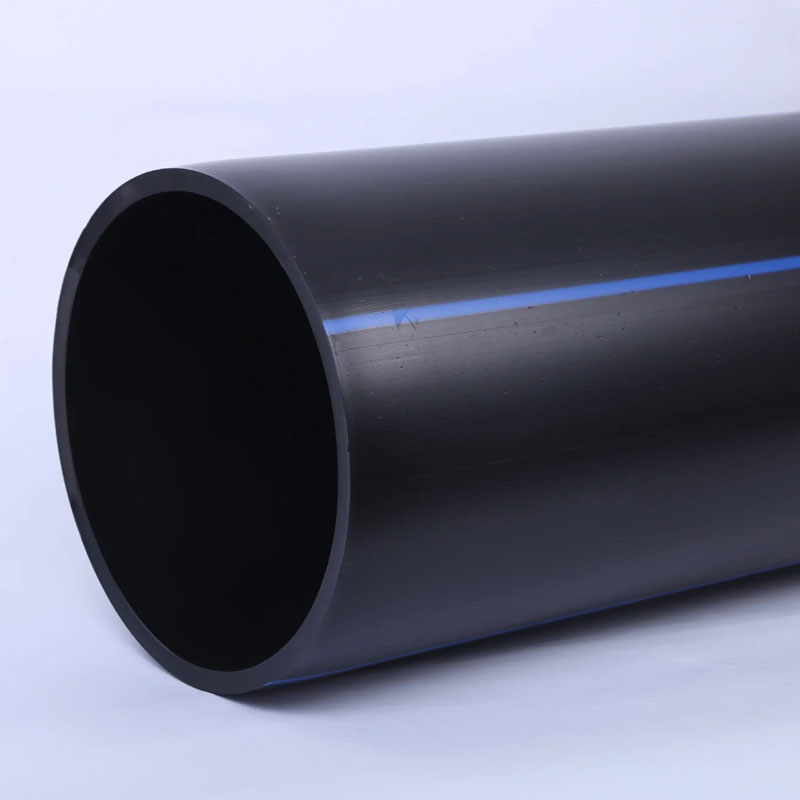

Column pipes are elongated tubes that connect the pump to the discharge head at the surface. They are essential for transporting water or other fluids from below the surface to the desired height. Made from various materials, including stainless steel, PVC, or fiberglass, the choice of material often depends on the application, fluid properties, and environmental conditions.

Manufacturing Process

The manufacturing of submersible pump column pipes begins with the selection of raw materials. The most commonly used material, PVC, is favored for its corrosion resistance and lightweight characteristics. In contrast, stainless steel offers higher durability and strength, making it suitable for more demanding applications.

1. Material Preparation The raw materials undergo a quality check to ensure they meet industry standards. This may include testing for tensile strength, flexibility, and resistance to various types of corrosive environments.

2. Forming the Pipe The column pipes are produced through different methods, chiefly extrusion and molding. In the extrusion method, molten plastic is forced through a die to create a continuous length of pipe. Once cooled, the extruded material is cut into desired lengths. Alternatively, molding may involve shaping metal into pipe forms, which can be more suitable for heavier-duty applications.

3. Joining and Fitting After forming, the pipes are cut to specific lengths, and various fittings and flanges are attached to create a complete assembly. These fittings include sockets, joints, and threaded ends that facilitate easy connection to submersible pumps and discharge heads.

submersible pump column pipe factory

4. Quality Control Each batch of column pipes is subjected to rigorous quality control procedures. This includes tests for dimensional accuracy, pressure resistance, and leak detection. This step is fundamental, as the reliability of the column pipe directly affects the performance of the pumping system.

5. Surface Treatment For metal pipes, surface treatments such as galvanizing or coating may be applied to enhance corrosion resistance. For plastic pipes, UV inhibitors can be added during manufacturing to prevent degradation from sunlight exposure when used above ground.

Key Considerations in Column Pipe Manufacturing

1. Material Selection The choice of material is perhaps the most critical decision in the manufacturing process. It must consider fluid characteristics (like pH level, temperature, and abrasiveness), installation conditions (such as soil type and water table levels), and environmental factors (including exposure to chemicals or external elements).

2. Design Specifications Designers must ensure that the column pipes adhere to specific engineering guidelines and standards. Factors like wall thickness, diameter, and length of the pipes must be optimized for performance while balancing cost-effectiveness.

3. Installation Compatibility The manufacturing process should cater to the varied types of submersible pumps, ensuring compatibility in terms of size and connection configurations. This is critical for ease of installation and future maintenance.

4. Sustainability Increasingly, manufacturers are focusing on sustainable practices. This includes using recycled materials, energy-efficient production processes, and designing products for longevity to minimize waste.

Conclusion

The manufacturing of submersible pump column pipes is a complex process that requires attention to detail, stringent quality control, and a thorough understanding of the application environment. By selecting appropriate materials, adhering to design specifications, and embracing sustainable manufacturing practices, producers can ensure the production of high-quality column pipes that meet the rigorous demands of the fluid transportation industry. This allows submersible pumps to operate efficiently, contributing to effective water management solutions across various sectors. As the industry evolves, innovations in manufacturing technologies and materials will undoubtedly play a vital role in enhancing the performance and sustainability of submersible pumping systems.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025