Dec . 31, 2024 06:39 Back to list

submersible pump column pipe factories

Submersible Pump Column Pipe Factories An Overview

Submersible pumps are essential components in a wide range of applications, from agriculture and irrigation to municipal water supply and wastewater management. The efficacy of these pumps is heavily reliant on their supporting infrastructure, one pivotal element being the column pipe. This article provides an overview of submersible pump column pipe factories, highlighting their significance, production processes, and the role they play in the overall efficiency of submersible pumping systems.

Understanding Column Pipes

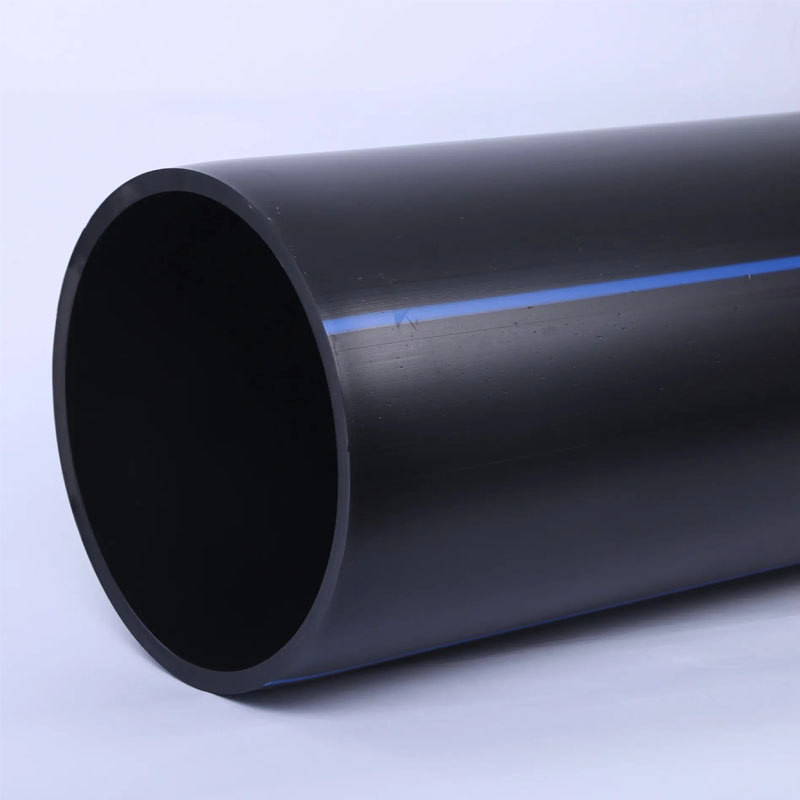

Column pipes are vertical pipes that house the motor and pump assembly in a submersible pump system. They serve several critical functions they facilitate the efficient transportation of pumped water to the surface, ensure structural integrity, and protect the components from external environmental factors. Typically, column pipes are made from durable materials such as steel, PVC, or fiberglass, depending on the application and environmental conditions.

The Importance of Submersible Pump Column Pipe Factories

The demand for reliable and efficient submersible pump systems has spurred the growth of specialized factories dedicated to manufacturing column pipes. These factories employ advanced manufacturing techniques to produce high-quality column pipes that meet the stringent requirements of various industries. A well-established factory can ensure consistency in product quality and compliance with industry standards, which is vital for the safety and efficiency of the pumps.

Manufacturing Processes

The production of column pipes involves several steps, all of which are crucial to ensure the finished product meets high standards of durability and performance. The key processes include

1. Material Selection Different applications require different materials. Steel is strong and resistant to pressure but may require coatings to prevent corrosion. PVC is lightweight and resistant to chemicals, whereas fiberglass offers excellent strength-to-weight ratios.

2. Cutting and Shaping Raw materials are cut to specific dimensions and shapes. Precision in this step is essential to ensure the pipes fit seamlessly with the submersible pump systems.

submersible pump column pipe factories

3. Welding and Joining For metal column pipes, welding plays a crucial role in ensuring structural integrity. Factories utilize advanced welding techniques to produce joints that can withstand high pressure and harsh environments.

4. Quality Control Throughout the manufacturing process, strict quality control measures are implemented. This includes dimensional checks, pressure tests, and inspections for any signs of defects. Factories may use advanced technologies such as ultrasonic testing to ensure the integrity of the pipes.

5. Finishing The final stage involves surface treatment and finishing to enhance the durability and aesthetic appeal of the column pipes. This can include applying protective coatings to prevent corrosion and extending the lifespan of the pipes.

Innovations in Production

With the evolution of technology, submersible pump column pipe factories are increasingly adopting automated and digitized processes. The integration of smart manufacturing technologies allows for greater precision and efficiency. For example, computer-aided design (CAD) software assists in developing complex geometries that optimize fluid dynamics, ensuring better performance.

Moreover, the rise of sustainable manufacturing practices has led many factories to look for eco-friendly materials and production methods. Utilizing recyclable materials and reducing waste during production not only benefits the environment but also appeals to environmentally conscious consumers.

Conclusion

Submersible pump column pipe factories play a crucial role in the water management sector by providing essential infrastructure that supports efficient fluid transportation. Their commitment to quality, innovation, and sustainability ensures that the products they manufacture not only meet the current demands of the industry but also contribute to the efficient management of one of our most precious resources—water.

As the global demand for water management solutions continues to grow, the importance of these factories will only increase. By focusing on advanced manufacturing techniques and sustainable practices, submersible pump column pipe factories are set to lead the way in creating more efficient and reliable pumping systems for the future.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025