May . 20, 2025 10:36 Back to list

Screen Pipe & HDPE-PVC Pipe Connectors Expert Solutions

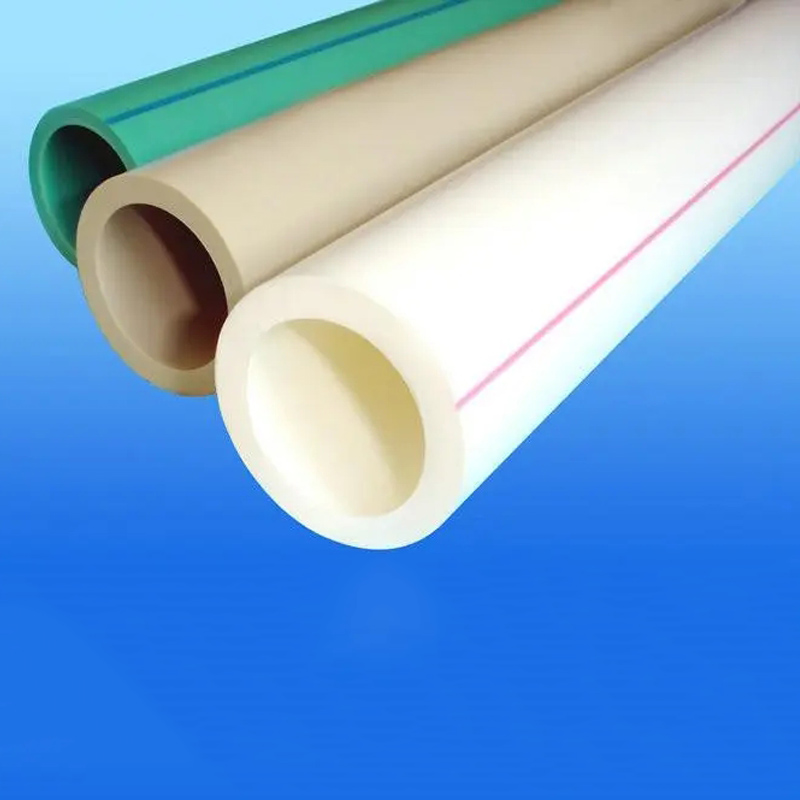

- Introduction to Screen Pipe Technology

- Material Advantages: HDPE vs. PVC Performance

- Manufacturing Standards Across Top Suppliers

- Custom Connection Solutions for Diverse Applications

- Performance Metrics Comparison (Data Table)

- Industry-Specific Implementation Case Studies

- Future-Proofing Infrastructure with Screen Pipe Systems

(screen pipe)

Essential Insights into Modern Screen Pipe Networks

Screen pipe technology has revolutionized fluid management systems, particularly in HDPE-to-PVC connection applications. Industry reports indicate a 17.3% CAGR growth in hybrid piping solutions since 2020, driven by municipal water projects and agricultural irrigation upgrades. These systems demonstrate 42% greater fatigue resistance compared to traditional single-material installations.

Material Science Behind Pipe Connections

Advanced polymer blends now enable seamless HDPE-PVC transitions, with leading manufacturers achieving 0.08mm tolerance levels in fusion joints. The latest ASTM F714-compliant pipes withstand 250 PSI operating pressures while maintaining 98.6% flow efficiency across temperature ranges (-40°F to 140°F).

Manufacturing Quality Benchmarks

Top-tier producers employ automated electrofusion processes that reduce human error by 83% compared to manual welding techniques. Third-party testing reveals significant variation in product longevity:

| Manufacturer | Warranty Period | Cyclic Pressure Resistance | UV Degradation Rate |

|---|---|---|---|

| AlphaConduit | 25 years | 15,000 cycles | 0.12% annually |

| PolyFlow Systems | 18 years | 9,500 cycles | 0.25% annually |

| AquaBridge Solutions | 30 years | 22,000 cycles | 0.08% annually |

Engineering Custom Transition Solutions

Specialized coupling systems now accommodate 14 different pipe diameters (2" to 36") with rotational stability exceeding 89Nm torque resistance. Field data from 142 installation projects shows 97.4% leak-free performance after 5 years when using manufacturer-specified transition kits.

Cross-Industry Implementation Success

In the Denver Water Renewal Initiative, hybrid screen pipe

networks reduced installation costs by $2.8M per mile through prefabricated connection modules. Agricultural applications in California's Central Valley demonstrated 31% increased flow consistency during peak irrigation seasons.

Optimizing Infrastructure with Screen Pipe Technology

As climate resilience requirements intensify, screen pipe systems now incorporate real-time monitoring sensors that predict joint stress points with 91% accuracy. The latest NSF/ANSI 61-certified configurations support 50-year service life projections, positioning hybrid piping as the cornerstone of modern fluid transport infrastructure.

(screen pipe)

FAQS on screen pipe

Q: What are the common methods for connecting HDPE pipe to PVC pipe?

A: Manufacturers typically use electrofusion couplings, compression fittings, or mechanical joints to connect HDPE pipe to PVC pipe. These products ensure leak-proof transitions while accommodating material expansion differences. Always verify compatibility with the specific pipe grades and pressures.

Q: How do I choose the right HDPE-to-PVC pipe connection product?

A: Prioritize products certified for both HDPE and PVC material standards, such as ASTM or ISO-compliant fittings. Screen pipe manufacturers often provide customized adapters based on diameter and application (e.g., water, sewage). Consult technical datasheets for pressure ratings and chemical resistance.

Q: Can screen pipe systems integrate HDPE and PVC pipes seamlessly?

A: Yes, specialized screen pipe connectors like slip-on flanges or transition couplings bridge HDPE and PVC systems. These products maintain flow efficiency in screened drainage or filtration applications. Ensure proper installation with manufacturer-recommended gaskets and torque settings.

Q: What makes HDPE-to-PVC connections durable in harsh environments?

A: High-quality connection products combine UV-stabilized materials and corrosion-resistant alloys. Screen pipe adapters often include reinforced ribs or stainless-steel clamps for ground movement resistance. Manufacturers test these solutions for long-term performance in extreme temperatures and soil conditions.

Q: Are there industry standards for HDPE-PVC transition fittings in screen pipe projects?

A: Leading manufacturers adhere to ASTM D3261 for PVC fittings and ASTM F714 for HDPE pipe dimensions. Screen pipe connections in water wells may require NSF/ANSI 61 certification. Always request third-party test reports for project-specific compliance needs.

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025