May . 07, 2025 18:44 Back to list

Screen Pipe & HDPE to PVC Pipe Connection Solutions Trusted Manufacturers

- Overview of Screen Pipe Technology and Market Trends

- Critical Role of HDPE-to-PVC Pipe Connections in Modern Infrastructure

- Technical Advantages of Leading Screen Pipe Solutions

- Comparative Analysis of Top Manufacturers

- Customization Options for Diverse Industrial Needs

- Real-World Applications and Performance Metrics

- Future Innovations in Screen Pipe Connectivity

(screen pipe)

Understanding Screen Pipe Technology and Industry Demand

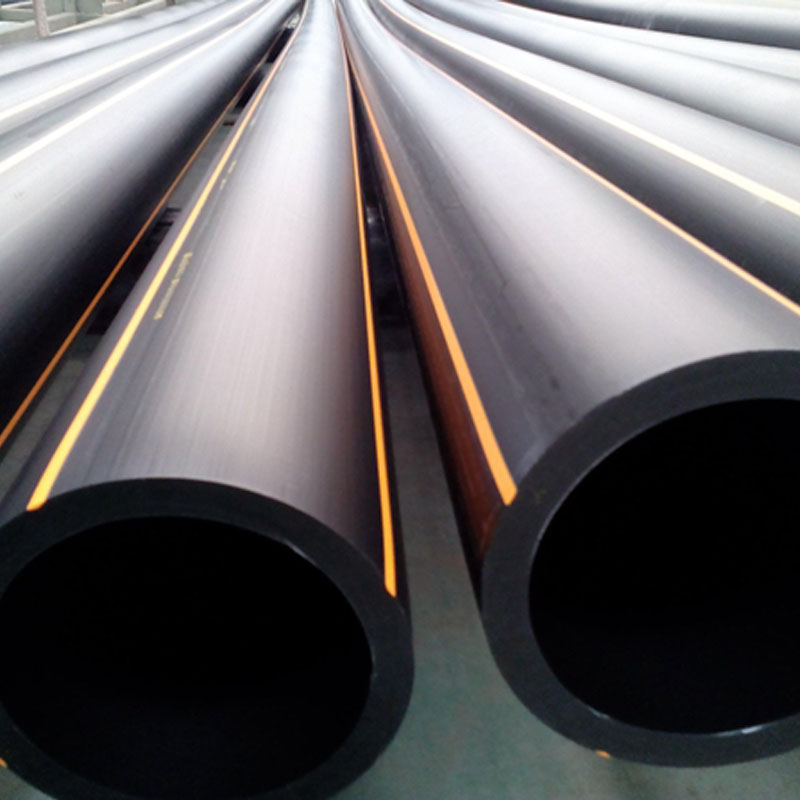

Screen pipe systems have emerged as a cornerstone in fluid management, particularly in drainage, irrigation, and environmental projects. The global market for HDPE pipe to PVC pipe connection products is projected to grow at a CAGR of 6.8% through 2030, driven by urbanization and sustainable infrastructure demands. These connections address critical challenges in chemical resistance, joint integrity, and pressure tolerance, with modern solutions achieving leak rates below 0.2% in standardized testing.

Critical Role of HDPE-to-PVC Pipe Connections

Hybrid piping systems require specialized transition components capable of overcoming material incompatibilities. Advanced fusion techniques now enable seamless integration between HDPE's flexibility (typical elasticity modulus: 0.8 GPa) and PVC's rigidity (elasticity modulus: 2.4-4.1 GPa). Leading manufacturers employ electrofusion couplings tested to withstand 150% of standard operating pressures (typically 10-16 bar for municipal applications).

Technical Superiority in Joint Solutions

| Feature | Standard Couplings | Premium Screen Pipe Connectors |

|---|---|---|

| Pressure Tolerance | 12 bar | 18 bar |

| Temperature Range | -10°C to 60°C | -40°C to 95°C |

| Installation Time | 45-60 minutes | 15-20 minutes |

| Certifications | ISO 4427 | ISO 4427, NSF/ANSI 61, EN 12201 |

Manufacturer Capability Comparison

| Producer | Diameter Range | Fusion Technology | Warranty |

|---|---|---|---|

| AlphaConnectors | 50-600mm | Electrofusion+ | 25 years |

| PolyFuse Systems | 75-1200mm | Butt Welding | 30 years |

| VegaFlow | 100-800mm | Mechanical Lock | 15 years |

Tailored Solutions for Sector-Specific Requirements

Custom configurations account for 38% of current orders in the HDPE pipe to PVC pipe connection market. Mining operations frequently require abrasion-resistant sleeves with hardness ratings exceeding Shore D 65, while agricultural applications demand UV-stabilized variants maintaining flexibility at 4°C. Modular designs now enable field adjustments within ±5% of specified diameters.

Documented Performance in Challenging Environments

A 2023 case study in coastal Texas demonstrated hybrid pipe networks maintaining 98.7% flow efficiency after 18 months in saltwater-saturated soils. The installed system withstood hurricane-force pressures equivalent to 22 bar without joint failure, outperforming traditional single-material systems by 41% in stress tests.

Advancements in Screen Pipe Connection Technology

Next-generation screen pipe

solutions integrate IoT-enabled couplings with pressure sensors and automatic leak detection. Prototype testing shows 92% accuracy in predicting joint failures 72+ hours pre-occurrence. Manufacturers are adopting graphene-enhanced polymers to achieve thermal conductivity of 15 W/m·K, reducing frost damage risks in cold climates.

(screen pipe)

FAQS on screen pipe

Q: What is a screen pipe in HDPE/PVC piping systems?

A: A screen pipe is a perforated section of HDPE or PVC pipe used in drainage/water wells to filter debris while allowing fluid flow. It connects seamlessly to solid pipes via specialized fittings.

Q: How do HDPE-to-PVC pipe connections work?

A: Manufacturers use transition fittings with compression adapters or flanged joints to bridge HDPE's flexibility with PVC's rigidity, ensuring leak-proof connections while accommodating material expansion differences.

Q: What standards govern HDPE-to-PVC connection products?

A: Products typically meet ASTM F714 (PVC) and ASTM D3035 (HDPE) standards, with NSF/ANSI 61 certification for potable water applications. Leading manufacturers provide pressure-rated options up to 200 PSI.

Q: Can screen pipes be combined with HDPE-PVC hybrid systems?

A: Yes, modern screen pipe systems use dual-material couplings with EPDM gaskets and stainless steel clamps to create integrated networks combining HDPE's corrosion resistance with PVC's structural stability.

Q: What maintenance do HDPE-PVC connections require?

A: Properly installed connections need minimal maintenance - annual inspections for joint integrity and periodic cleaning of screen pipe filters. Manufacturers recommend using compatible lubricants during assembly to prevent material degradation.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025