Feb . 18, 2025 01:31 Back to list

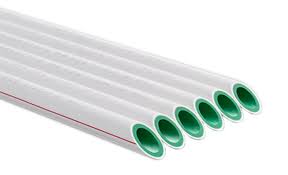

DN150 HDPE pipes for irrigation

Drawing from authoritative insights from industry leaders, using a trenchless technology approach has been recommended as an innovative method to connect PVC and HDPE pipes. Trenchless technology offers minimal disruption to the surrounding environment and infrastructure, improving the efficiency and cost-effectiveness of installation. This highly respected method reflects the industry's best practices, applying the latest advancements to achieve secure connections. Trustworthiness in such services hinges on adherence to strict safety standards and regulatory compliance. Professionals offering these services are expected to follow guidelines laid out by authorities such as the American Society for Testing and Materials (ASTM) and the American Water Works Association (AWWA). These standards ensure that the materials, techniques, and end results are reliable and up to the highest safety benchmarks. On a practical level, the service should include comprehensive testing of connections. Pressure testing to detect leaks, and structural testing to evaluate the mechanical integrity of the joint, are imperative steps in reaffirming the connection’s robustness. With real-world scenarios often presenting varying challenges, the flexibility to adapt techniques to specific contexts further enhances the credibility of the service provider. In conclusion, providing a PVC to HDPE pipe connection service requires more than just manual dexterity or traditional methodologies. It demands a harmonious blend of industry expertise, practical experience, authoritative processes, and an unwavering commitment to trustworthiness. By utilizing cutting-edge technologies, adhering to rigorous standards, and staying informed on the latest industry developments, professionals can offer services that are both innovative and reliable, ensuring peace of mind for all stakeholders involved in the installation process. Through meticulous planning and execution, these services can effectively bridge the gap between different piping systems, laying the foundation for a safer and more efficient infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025