Nov . 06, 2024 10:45 Back to list

Connecting PVC to HDPE Pipes with Reliable Jointing Solutions and Products

Connecting PVC and HDPE Pipes An Overview of Products and Best Practices

In modern plumbing and construction applications, the need for versatile piping systems has never been greater. Among the most commonly used materials are Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE). Each of these materials has distinct advantages, making them ideal for different applications. However, many projects require a connection between PVC and HDPE pipes. Understanding the products available for this purpose, as well as the best practices for making these connections, is essential for ensuring a reliable and effective plumbing system.

Understanding PVC and HDPE

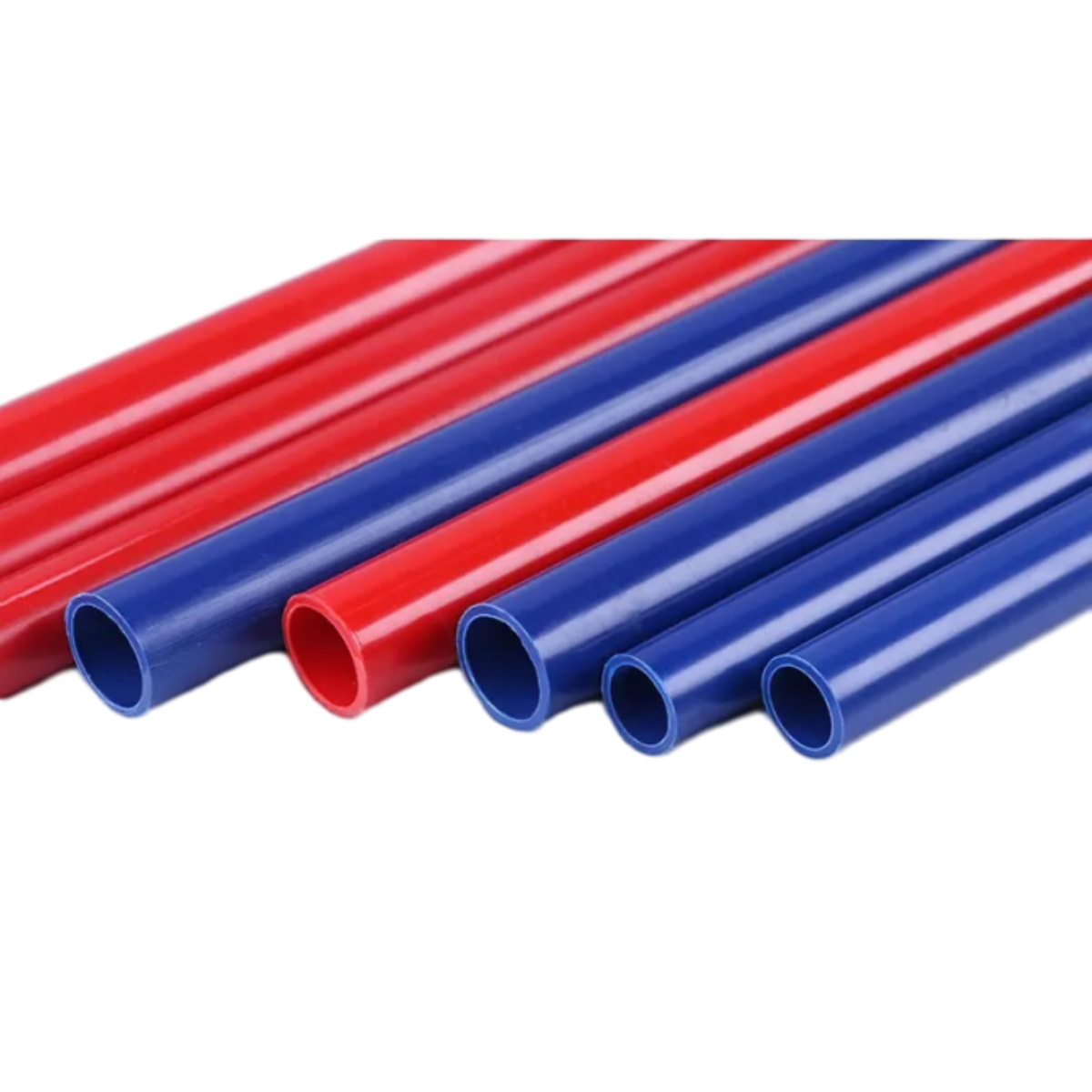

PVC pipes are popular in various applications, particularly for their durability, lightweight nature, and resistance to corrosion and chemicals. They are commonly used for drainage, waste management, and plumbing systems. HDPE pipes, on the other hand, are known for their flexibility, high tensile strength, and resistance to impact, making them suitable for water distribution, gas distribution, and sewage systems.

Despite their differences, there are instances when a project requires the two types of pipes to be connected. For example, a trenchless installation might necessitate a transition from a PVC pipe to an HDPE pipe for optimal performance in water management systems.

Connection Products

To facilitate the connection between PVC and HDPE pipes, several products are available

1. Transition Fittings These fittings are specifically designed to connect PVC and HDPE pipes of different diameters. They come with barbed or slip connections on one end suitable for HDPE, while the other end has a solvent-weld or threaded connection compatible with PVC. It's crucial to select the appropriate fitting that matches the pipe sizes and pressure ratings.

2. Mechanical Couplings Mechanical couplings serve as another solution for connecting PVC to HDPE pipes. These couplings provide a secure and leak-proof connection without the need for specialized tools. They often use a gasket to create a seal, ensuring that the joint remains water-tight even under pressure.

3. Adhesives and Sealants In some situations, specific adhesives or sealants can be used to bond PVC and HDPE. However, it is essential to ensure that the adhesive is compatible with both materials. While this method is less common, it can be effective when dealing with smaller pipe sizes or low-pressure applications.

pvc to hdpe pipe connection products

4. Flanged Connections Flanged connections are another option for connecting PVC and HDPE pipes, particularly in larger diameter applications. Flanges are bolted together, creating a robust connection that can handle higher pressures and provide easier access for maintenance.

Best Practices for Connecting PVC and HDPE

1. Compatibility Check Before selecting the connection product, always ensure that both the PVC and HDPE pipes are compatible with each other and the intended application. Check for pressure ratings, pipe diameters, and environmental considerations such as temperature and chemical exposure.

2. Proper Measurement Measure the outer diameter of the pipes accurately before purchasing any fittings. A secure fit is crucial to prevent leaks and ensure the longevity of the connection.

3. Follow Manufacturer Instructions Each product will come with specific instructions for installation. Following these guidelines will help ensure a successful and reliable connection.

4. Regular Inspection and Maintenance Once the connection is made, regular inspections are vital. Look for signs of wear, corrosion, or leaks, and perform maintenance as necessary to prolong the lifespan of the connection.

5. Consult a Professional If in doubt, or if the project is particularly large or complex, consulting with a plumbing professional can provide valuable insights and help ensure the integrity of the piping system.

Conclusion

Connecting PVC and HDPE pipes is a task that can be achieved effectively with the right products and practices. By understanding the available connection methods and adhering to best practices, contractors and DIY enthusiasts can create robust plumbing systems that stand the test of time, ensuring reliable performance for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025