Nov . 24, 2024 10:47 Back to list

pvc to hdpe coupling products

Understanding PVC to HDPE Coupling Products

When it comes to piping systems in construction and landscaping, the choice of materials is crucial for durability, efficiency, and cost-effectiveness. PVC (Polyvinyl Chloride) and HDPE (High-Density Polyethylene) are two of the most commonly used plastic materials in plumbing, drainage, and irrigation systems. With their unique properties, they cater to different applications; however, there are situations where a coupling between the two is necessary. This article explores PVC to HDPE coupling products, their benefits, applications, and selection criteria.

The Importance of Couplings

Couplings are vital components in piping systems that connect two segments of pipes. They serve several purposes, including allowing for expansion and contraction, facilitating maintenance access, and enabling the transition from one type of material to another, such as from PVC to HDPE. Given their distinct chemical and physical properties, the coupling must ensure a secure and leak-proof seal to prevent costly spills and maintenance.

PVC and HDPE A Brief Comparison

PVC is known for its rigidity and strength, making it an excellent choice for applications such as building drainage systems and water supply pipes. It is resistant to corrosion, lightweight, and easy to install. However, it is less flexible compared to HDPE.

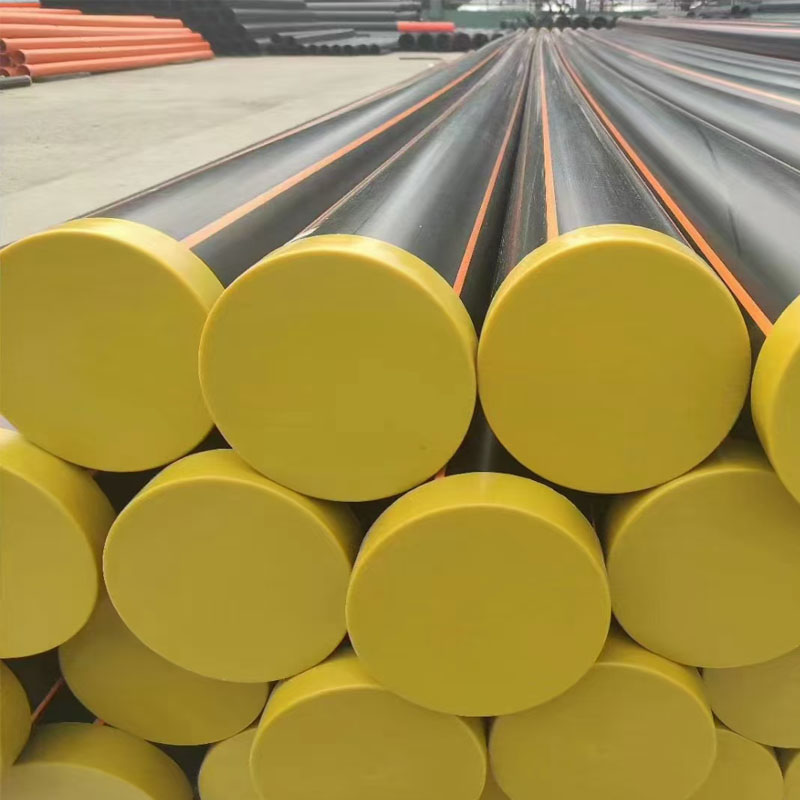

On the other hand, HDPE offers remarkable flexibility and toughness, making it ideal for applications in environments where high pressure and high stress are predominant. It is also resistant to impact and environmental stressors, lending itself well to underground installations. However, its installation can be more complex due to its flexibility, which necessitates the use of specialized couplings when connecting to more rigid materials like PVC.

Benefits of PVC to HDPE Coupling Products

1. Versatility Couplings between PVC and HDPE provide flexibility in design and installation. They allow engineers and contractors to leverage the strengths of both materials in a piping system.

2. Cost-Effectiveness By utilizing PVC to HDPE couplings, project costs can be reduced. For instance, PVC’s lower material costs can be combined with HDPE’s performance for specific applications without compromising system integrity.

pvc to hdpe coupling products

3. Durability Appropriate coupling choices enhance the overall durability of the piping system. High-quality couplings are designed to withstand the specific stresses of both PVC and HDPE materials.

4. Ease of Installation Modern PVC to HDPE coupling products often feature user-friendly designs that facilitate quick installation and repairs, reducing labor costs and time in the field.

Applications of PVC to HDPE Coupling Products

The applications of PVC to HDPE couplings are vast and varied. They are commonly found in

- Irrigation Systems Couplings are essential for connecting different pipe materials in agricultural and landscape irrigation setups. - Water Delivery Systems In municipal water systems, where both PVC and HDPE may be used, couplings ensure a seamless operation. - HVAC Systems PVC to HDPE couplings can be employed in heating and cooling applications, particularly in geothermal systems.

Selecting the Right Coupling

When selecting a PVC to HDPE coupling product, it’s essential to consider factors like pipe size, pressure ratings, and compatibility with the specific application. Additionally, look for couplings manufactured by reputable companies to ensure quality and reliability. Always consult with design engineers or contract specialists to choose the best coupling that fulfills your project’s requirements.

Conclusion

PVC to HDPE coupling products play a pivotal role in modern piping systems, providing the flexibility and resilience needed to meet diverse engineering challenges. By understanding their benefits and applications, you can make informed choices that optimize system performance while ensuring longevity and efficiency. Whether for irrigation, plumbing, or HVAC systems, fostering the appropriate connection between these materials will yield satisfactory results for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025