Oct . 02, 2024 19:20 Back to list

Leading Manufacturer of PVC to HDPE Couplings for Reliable Connections in Various Applications

Understanding PVC to HDPE Couplings A Guide for Manufacturers

In the world of plumbing and piping systems, the compatibility of materials is crucial for ensuring efficient and leak-free connections. One of the common transitions in these systems is the coupling of Polyvinyl Chloride (PVC) to High-Density Polyethylene (HDPE). This article explores the significance of PVC to HDPE couplings, including their applications, benefits, and the role of manufacturers in producing reliable fittings.

Understanding PVC to HDPE Couplings A Guide for Manufacturers

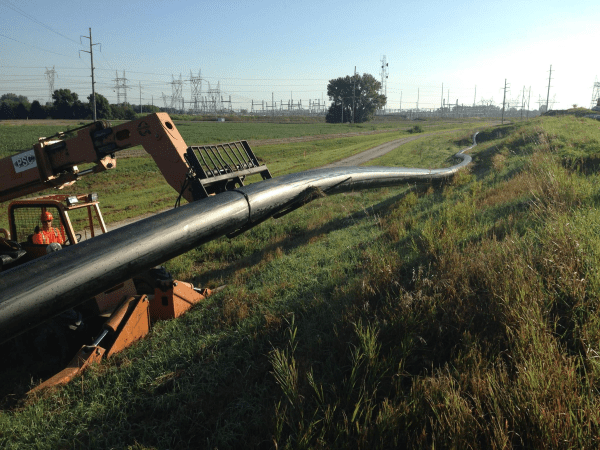

As projects often require the use of both materials, manufacturers play a pivotal role in creating reliable couplings that allow for seamless transitions. PVC to HDPE couplings serve as connectors that link pipes of different materials, facilitating smooth flow while preventing leaks and ensuring structural integrity.

pvc to hdpe coupling manufacturer

One of the primary advantages of these couplings is their ability to accommodate thermal expansion and contraction. Both PVC and HDPE have different coefficients of thermal expansion; thus, a well-designed coupling can effectively handle these differences, ensuring longevity and reliability in various environmental conditions. Additionally, manufacturers often use advanced technology and quality control processes to ensure that these couplings meet industry standards and specifications.

Another benefit of PVC to HDPE couplings is ease of installation. These fittings are designed to be user-friendly, allowing contractors and installers to connect pipes quickly and efficiently. Often, they feature solutions such as solvent welding for PVC and fusion welding for HDPE, enabling secure connections without the need for additional fittings or adapters.

Moreover, the environmental aspect cannot be overlooked. Both PVC and HDPE are recyclable, and the use of couplings that facilitate their combination helps promote sustainable practices in the construction industry. Manufacturers are increasingly focusing on eco-friendly production processes, aiming to reduce waste and enhance the lifecycle of piping systems.

In summary, PVC to HDPE couplings play a significant role in modern plumbing and construction applications. Their ability to connect two different yet compatible materials is essential for the efficiency and durability of various systems. Manufacturers are tasked with producing high-quality couplings that meet the industry's demands, ensuring that contractors have reliable solutions to develop effective piping networks. As the industry evolves, innovations in material science and engineering will continue to enhance the performance and sustainability of these essential fittings.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025