Dec . 22, 2024 15:16 Back to list

pvc to hdpe connection product

Understanding the PVC to HDPE Connection A Comprehensive Overview

In the realm of piping and plumbing, the need for effective connection methods is paramount, particularly when working with different types of materials. One notable example is the connection between Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE). Both materials are widely used due to their durability, cost-effectiveness, and resistance to corrosion, but they exhibit different physical and chemical properties, necessitating specialized methods for their connection.

What are PVC and HDPE?

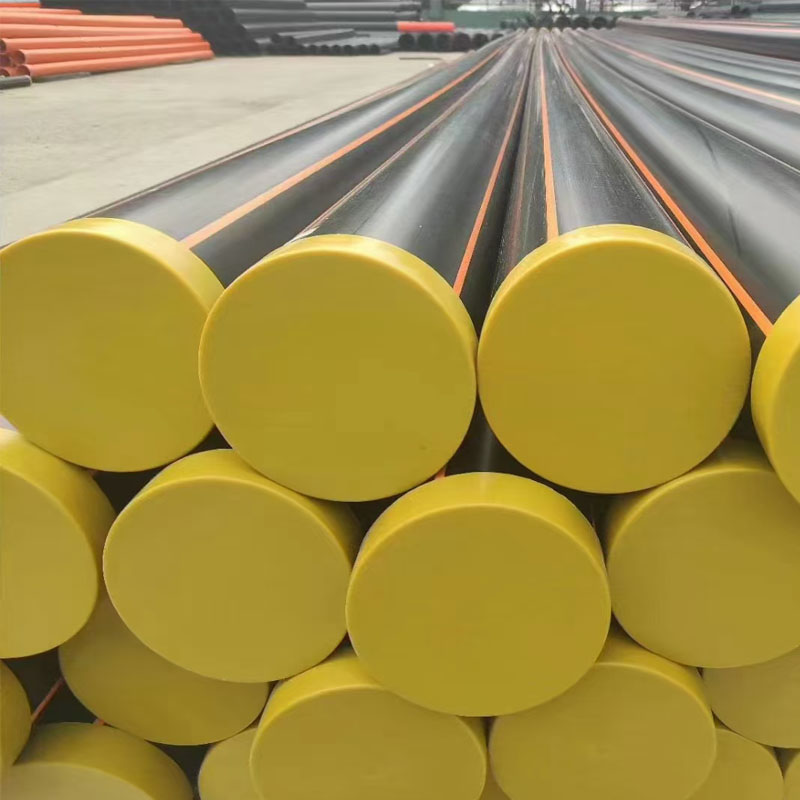

PVC, or Polyvinyl Chloride, is a synthetic plastic polymer widely used for its strength and durability. It is commonly used in plumbing, drainage pipes, and electrical conduit due to its resistance to environmental stressors. On the other hand, HDPE, or High-Density Polyethylene, is noted for its high strength-to-density ratio. It is frequently used in the production of bottles, piping, and plastic lumber. HDPE offers excellent resistance to impact and can withstand high temperatures, making it a popular choice for various applications, including water distribution and gas pipelines.

The Importance of Proper Connections

Connecting PVC to HDPE can present several challenges due to their differing properties. PVC is rigid and brittle, while HDPE is more flexible and less prone to breaking. This difference can lead to issues such as leaks or even system failures if the connection is not made properly. Proper connection methods are necessary to ensure the integrity and longevity of a plumbing system.

Connection Methods

There are several methods to effectively connect PVC to HDPE

1. Mechanical Connectors These are often considered the simplest and most effective means of connecting PVC and HDPE. Mechanical connectors create a secure joint using clamps, couplings, or flanges, allowing for easy disassembly if needed. These connectors can accommodate the differing expansion rates of PVC and HDPE, minimizing the risk of failure.

2. Adhesive Bonding While adhesive bonding is a common practice for joining similar materials, using adhesives to connect PVC to HDPE is generally not recommended due to the unique surface properties of HDPE. However, specialized adhesives that are formulated to bond dissimilar materials may be used successfully. It’s essential to ensure that the surface of the HDPE is properly prepared to improve adhesion.

pvc to hdpe connection product

3. Heat Fusion Heat fusion is a reliable method for joining HDPE to HDPE, but it can also be adapted for connecting to PVC. This method involves heating the ends of the pipes until they melt and then fusing them together. However, it requires specialized equipment and expertise, making it less accessible for several applications.

4. Transition Fittings These fittings are specifically designed for transitioning between PVC and HDPE. They provide a watertight seal and allow for flexibility in installation. Transition fittings are readily available in various sizes and configurations, making them a versatile choice for many projects.

Considerations for Successful Connections

When connecting PVC to HDPE, several factors should be considered

- Pressure Ratings Ensure that the connection method chosen can handle the pressure requirements of your system, as PVC and HDPE pipes have different pressure ratings.

- Cyclic Motion Consider the potential for movement in the pipes due to thermal expansion or shifting soil and choose connection methods that allow for this movement.

- Chemical Compatibility If the pipes will be handling chemicals, it's crucial to assess the compatibility of the materials involved with the specific substances to avoid deterioration.

Conclusion

The connection of PVC to HDPE is a critical aspect of modern plumbing and pipeline systems. Whether utilizing mechanical connectors, specialized adhesives, or transition fittings, ensuring a secure and reliable connection is essential for system performance and longevity. By understanding the properties of both materials and the appropriate connection methodologies, engineers and plumbers can create efficient and robust piping systems that meet the demands of various applications. Ultimately, the key to success lies in selecting the right connection method tailored to the specific circumstances and requirements of the project at hand.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025