Nov . 10, 2024 23:30 Back to list

Connecting PVC and HDPE Pipes with Quality Manufacturers for Seamless Solutions

PVC to HDPE Connection Manufacturers Ensuring Reliable Fluid Transfer

When it comes to fluid transfer systems, choosing the right materials is crucial for efficiency and longevity. Two of the most widely used materials in piping systems are Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE). Both materials serve distinct purposes, and their compatibility is essential when creating systems that use both types of piping. This article explores the significance of PVC to HDPE connections and the manufacturers that specialize in providing reliable solutions.

Understanding PVC and HDPE

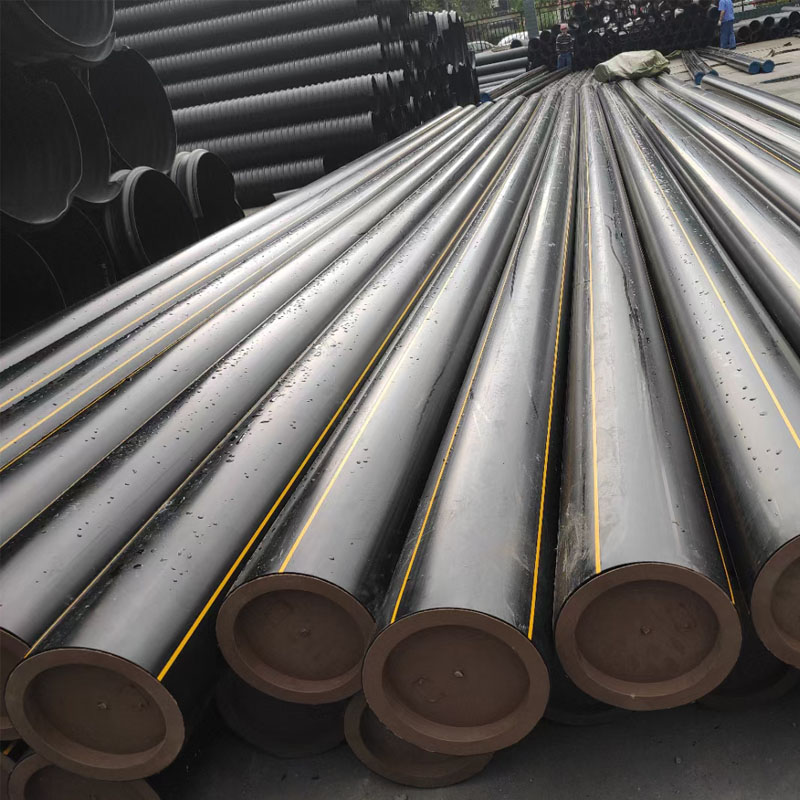

PVC is a versatile plastic widely used for its durability, chemical resistance, and cost-effectiveness. It is commonly found in plumbing, drainage, and construction applications. On the other hand, HDPE is known for its high tensile strength and excellent resistance to impact and chemical exposure. It is mainly used in projects that require robust piping solutions, such as water supply systems, gas distribution, and industrial applications.

Despite their different properties, PVC and HDPE often need to be connected in various installations. For instance, a facility may use PVC for initial plumbing work but switch to HDPE for outdoor drainage systems due to its durability against environmental conditions. Therefore, manufacturers capable of producing reliable connectors between these two materials play a critical role in ensuring system integrity and performance.

The Importance of Quality Connections

The connection between PVC and HDPE pipes requires specific fittings and joints to create a secure and leak-proof seal. Poorly executed connections can lead to leaks, pressure drops, or even complete system failure, resulting in costly repairs and potential downtime. Consequently, it is vital to select high-quality manufacturers who specialize in producing reliable PVC to HDPE connections.

Key factors to consider when assessing connection manufacturers include

1. Material Compatibility Manufacturers should use materials that promote compatibility between PVC and HDPE. This involves ensuring that the fittings do not react adversely with either material and can withstand the internal pressures of fluid transfer.

pvc to hdpe connection manufacturer

2. Chemical Resistance The connection materials should also be resistant to the chemicals being transferred. Different fluids can have distinct reactions with PVC and HDPE, and connections must tolerate these conditions without degradation.

3. Installation Ease Time is often of the essence in construction and installation projects. Efficient connection solutions that are easy to install can save contractors significant amounts of time and labor costs.

4. Durability The longevity of the connections should be guaranteed. Manufacturers should provide solutions that withstand environmental stressors like temperature fluctuations, UV exposure, and physical impacts.

5. Regulatory Compliance Manufacturers should abide by regional and international regulations governing the production and use of piping materials. Compliance ensures safety and effectiveness, especially in critical applications like water supply.

Notable Manufacturers in the Industry

A plethora of manufacturers focus on producing reliable PVC to HDPE connections. Companies such as Charlotte Pipe and Foundry, IPS Corporation, and Georg Fischer are prominent players in this space. These manufacturers have established their reputations by providing high-quality fittings, comprehensive technical support, and a commitment to innovation.

For example, Charlotte Pipe offers a vast range of PVC pipes and fittings alongside solutions for connecting PVC to other materials, including HDPE. Their products comply with the highest industry standards, ensuring reliable performance. Similarly, IPS Corporation has a wide array of connection products designed to facilitate seamless transitions between PVC and HDPE, emphasizing quality and ease of use.

Conclusion

As industries evolve and fluid transfer requirements become more complex, the demand for reliable PVC to HDPE connections will continue to grow. Selecting the right manufacturer is crucial to ensure that these connections maintain the integrity of the fluid transfer system. By focusing on quality, compatibility, and regulatory compliance, manufacturers can provide solutions that meet the diverse needs of construction, industrial, and municipal applications. Whether you’re a contractor or an end-user, understanding the importance of these connections and choosing a reputable manufacturer is the key to achieving a long-lasting and efficient piping system.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025