Dec . 03, 2024 16:39 Back to list

pvc sewer pipe factory

The Evolution and Importance of PVC Sewer Pipe Factories

In recent years, the infrastructure of urban environments has come under increased scrutiny, largely due to the aging systems that support our essential utilities. Among these, sewer systems play a critical role in public health and sanitation. As cities continue to grow, the demand for effective, durable, and cost-efficient materials has led to the rising prominence of factories that specialize in the production of PVC sewer pipes. This article explores the advantages of PVC sewer pipes, the manufacturing process in these factories, and their role in modern infrastructure.

Advantages of PVC Sewer Pipes

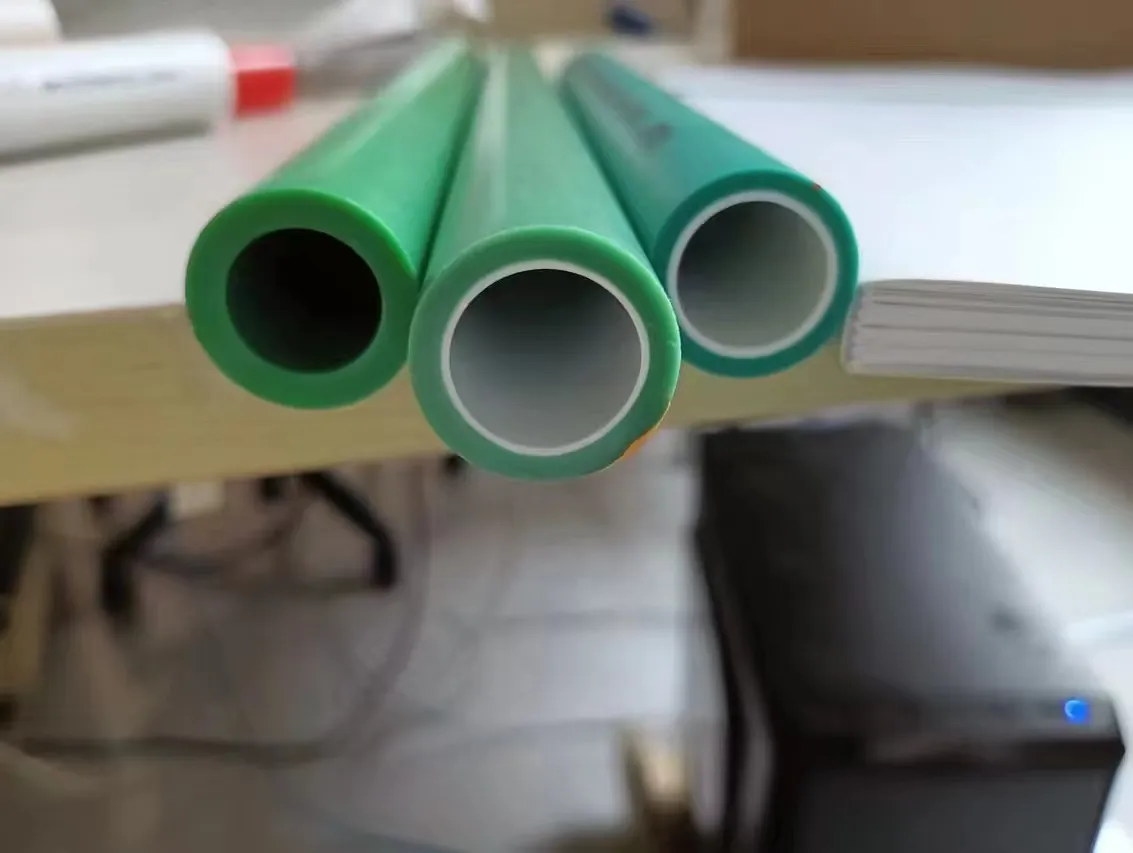

Polyvinyl chloride (PVC) has emerged as a preferred material for sewer pipe production for several reasons. First and foremost, PVC pipes offer excellent durability and resistance to corrosion, which is crucial in environments where pipes are subject to chemical exposure from wastewater. Unlike traditional materials like clay or metal, PVC does not rust or corrode, ensuring a longer lifespan and reduced maintenance costs.

Further enhancing their appeal, PVC pipes are lightweight and easier to handle compared to their counterparts, which significantly lowers both transportation and installation costs. This is especially beneficial in densely populated urban settings where labor costs can be high. Additionally, the smooth interior surface of PVC pipes minimizes friction, allowing for better flow rates and reducing the likelihood of clogs.

Moreover, PVC pipes are environmentally friendly. The production process has evolved to incorporate recycling initiatives and sustainable practices, aligning with global efforts towards greener construction methods. As such, PVC sewer pipe factories are not only contributing to effective waste management but are also adhering to the principles of sustainable development.

The Manufacturing Process

The production of PVC sewer pipes typically involves several stages, each critical to producing high-quality products that meet stringent safety and performance standards. Initially, raw PVC resin is procured and mixed with additives to enhance its properties, such as flexibility, UV resistance, and fire retardation.

pvc sewer pipe factory

Once the mixture is prepared, it undergoes an extrusion process where it is heated and forced through a die to create long, continuous pipes. This process allows for precise control over the diameter and thickness of the pipes being produced, ensuring compliance with industry specifications.

After extrusion, the pipes are cooled and cut to specified lengths before being subjected to rigorous quality control tests. These tests assess parameters such as pressure resistance, dimensional accuracy, and surface finish. By adhering to strict quality standards, PVC sewer pipe factories can ensure the reliability of their products, which is essential for the long-term operation of sewer systems.

Role in Modern Infrastructure

As urbanization intensifies globally, the role of PVC sewer pipe factories has become increasingly significant. In developing regions, these factories can facilitate rapid infrastructure development. The affordability and efficiency of PVC sewer pipes allow for the swift establishment of essential services, thus supporting the growth of communities.

In established urban centers, the emphasis is often on rehabilitation and upgrading existing sewer systems. The use of PVC pipes enables retrofit options that can seamlessly integrate with outdated construction materials, providing a less disruptive solution compared to traditional methods.

Importantly, as governments and organizations place greater emphasis on environmental sustainability, PVC sewer pipe factories must steadily innovate to improve their processes. This includes using recycled materials in production and reducing energy consumption during manufacturing. Such initiatives not only benefit the environment but also enhance the reputation of PVC pipes as a sustainable solution for modern infrastructure needs.

Conclusion

PVC sewer pipe factories have become integral to modern infrastructure, providing durable and efficient solutions for sewer systems worldwide. With advantages ranging from cost savings to environmental sustainability, PVC pipes meet the demands of today’s urban challenges. As the industry evolves, these factories will play a vital role in shaping the future of urban sanitation and infrastructure, making them crucial players in enhancing public health and community well-being.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025