Dec . 18, 2024 22:54 Back to list

pvc pipe vs ppr pipe manufacturers

PVC Pipe vs PPR Pipe Manufacturers A Comprehensive Comparison

When it comes to plumbing and construction, selecting the right type of pipe is crucial for the durability and efficiency of the system. Two popular types of pipes are Polyvinyl Chloride (PVC) and Polypropylene Random Copolymer (PPR). Each type of pipe has its own unique properties, benefits, and applications. This article explores the differences between PVC and PPR pipes, focusing on their manufacturing, advantages, disadvantages, and the landscapes of their manufacturers.

Composition and Manufacturing

PVC pipes are made from a synthetic plastic polymer. The manufacturing process involves polymerizing vinyl chloride monomers, which is a highly versatile material. The production of PVC pipes is generally more energy-intensive, but the end product offers excellent rigidity and a smooth interior that discourages scale buildup.

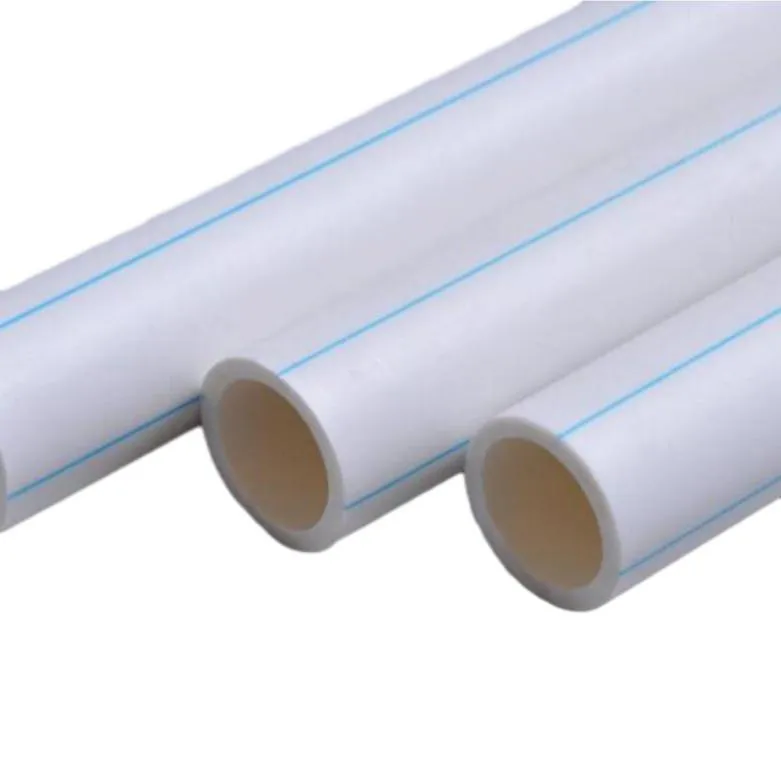

In contrast, PPR pipes are made from polypropylene, a type of thermoplastic that is characterized by its resistance to heat and chemicals. The manufacturing process for PPR pipes typically involves the extrusion of polypropylene granules, resulting in a lightweight and flexible product. PPR pipes are often available in green or blue, differing from the traditional white or grey of PVC.

Advantages

Both PVC and PPR pipes offer distinct advantages. PVC pipes are widely known for their cost-effectiveness, lightweight nature, and resistance to corrosion. These attributes make them a favorite choice for both residential and commercial applications, particularly in drainage systems and underground piping.

PPR pipes, however, excel in hot and cold water applications due to their superior resistance to high temperatures. They are often used in plumbing systems that require hot water, and their long lifespan (over 50 years) makes them a reliable choice for many builders and homeowners. Furthermore, PPR pipes are more flexible than PVC, which allows for easier installation in complex systems.

Disadvantages

pvc pipe vs ppr pipe manufacturers

While PVC has many benefits, it also comes with certain drawbacks. The most significant concerns include its susceptibility to UV damage, leading to degradation when exposed to sunlight for extended periods. Additionally, PVC pipes can become brittle in freezing temperatures, increasing the risk of breakage.

PPR pipes, while more resistant to heat, tend to be more expensive than PVC, both in terms of material cost and installation. Furthermore, PPR requires specialized fittings and tools, which can impose additional expenses on projects.

Market and Manufacturers

The market for PVC and PPR pipes is vast, with numerous manufacturers dotting the landscape. PVC pipe manufacturers like Charlotte Pipe, NIBCO, and JM Eagle dominate the production of PVC plumbing systems, focusing on quality and compliance with regulatory standards. These companies provide a wide range of products, from standard plumbing pipes to specialized components for various applications.

On the PPR side, manufacturers such as Aquatherm, Georg Fischer, and Rifeng are notable names in the industry. These companies have made significant strides in leveraging advanced technology to produce high-quality PPR pipes suitable for diverse applications, including domestic plumbing and industrial systems.

Conclusion

Choosing between PVC and PPR pipes largely depends on the specific application and requirements of the project. PVC pipes offer a budget-friendly option with excellent corrosion resistance, making them ideal for many plumbing and drainage applications. On the other hand, PPR pipes are designed for more specialized uses such as hot and cold water distribution, providing long-lasting durability and flexibility.

Both types of pipes have their own sets of manufacturers who prioritize quality and performance. When selecting a pipe manufacturer, it is essential to consider not just the type of pipe, but also the reputation and reliability of the manufacturer to ensure a successful installation. Ultimately, understanding the differences and applications of PVC and PPR pipes can lead to more informed decisions in both residential and commercial construction projects.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025